Metal halide perovskites have emerged as promising materials for developing photovoltaic technology due to their advantageous optoelectronic properties. Recent studies have demonstrated metal halide perovskite-based solar cells (PSCs) with power conversion efficiencies (PCEs) above 25.8%, rivaling some solar technologies on the market today. However, the existing fabrication processes for these solar cells are far from ideal. This article explores a recent breakthrough in fabricating metal halide perovskite solar cells with PCEs above 25% in ambient air conditions.

To achieve high PCEs above 25%, metal halide perovskite solar cells have traditionally been fabricated in an inert atmosphere, such as within a nitrogen glovebox. This requirement poses a significant limitation to large-scale production and deployment, as it adds additional fabrication costs. Moisture-induced decomposition of the perovskite layer is a major issue, as it leads to the degradation of the material and limits the device efficiency.

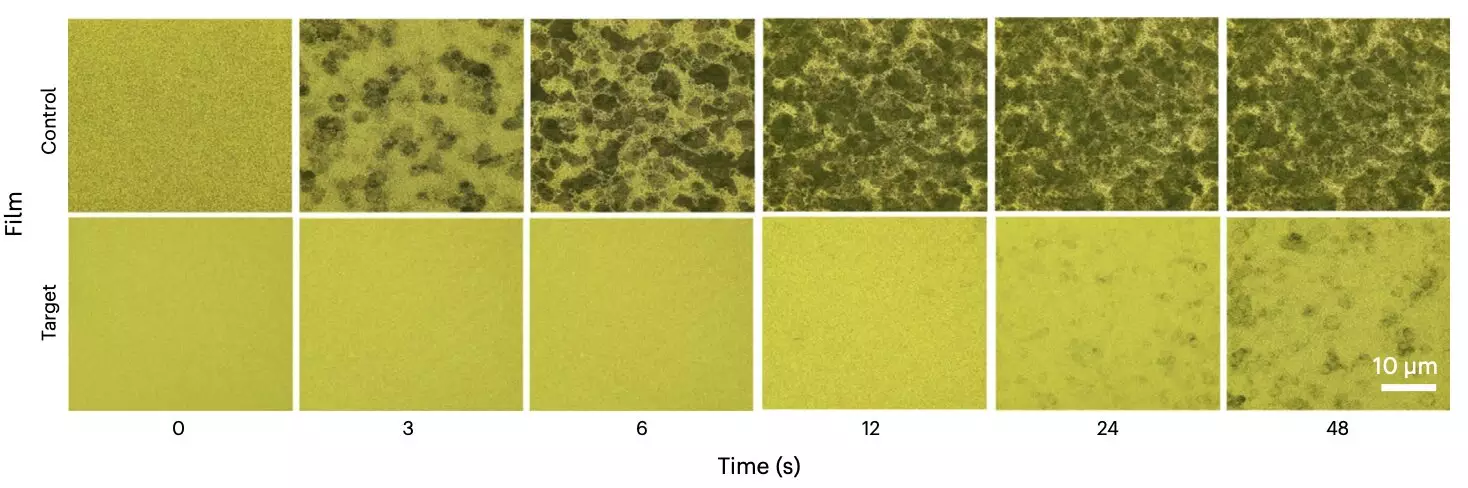

In a groundbreaking paper published in Nature Energy, researchers at North China Electric Power University introduced a strategy to fabricate metal halide PSCs with PCEs above 25% in ambient air conditions. The team, led by Luyao Yan and Hao Huang, successfully blocked the pathway through which the perovskite layers become hydrated, using the acetate salt form of the chemical compound guanabenz, known as GBA. This innovative approach eliminates both cation and anion vacancies, allowing the crystallization of a high-quality film in ambient air.

Initial tests of the proposed fabrication strategy yielded remarkable results, demonstrating the successful creation of stable metal halide perovskite solar cells with commercially viable PCEs above 25%. These solar cells also maintained their performance over time, even after operating in humid environments. After 2,000 hours of aging in ambient air and 500 hours of operating at the maximum power point under simulated air mass in a nitrogen atmosphere, the PSCs without encapsulation retained around 96% of their initial efficiency. Encapsulated devices retained 85% of their initial efficiency even after 300 hours under damp heat conditions. These findings showcase the potential of metal halide PSCs fabricated in ambient air for long-term stability.

The breakthrough achieved by Yan, Huang, and their colleagues at North China Electric Power University offers a new avenue for the low-cost fabrication of metal halide perovskite solar cells. By overcoming the limitations of traditional fabrication processes, this strategy paves the way for large-scale production and deployment of these highly efficient solar cells. Furthermore, the researchers anticipate that their innovative approach can be further adapted and perfected to enhance the performance of metal halide PSCs in the future, driving their commercialization.

Metal halide perovskite solar cells hold great promise for the future of photovoltaic technology. The recent breakthrough in fabricating these solar cells in ambient air conditions, achieving PCEs above 25%, is a significant step toward their commercialization. By eliminating the need for an inert atmosphere during fabrication, the new strategy offers a cost-effective approach for mass production. The remarkable stability demonstrated by these solar cells further strengthens their potential for long-term use. As researchers continue to refine and optimize the fabrication process, metal halide perovskite solar cells may soon become a competitive and sustainable solution in the renewable energy landscape.

Leave a Reply