The quest for finding sustainable alternatives to replace petroleum-based plastic films has gained momentum in recent years. In a remarkable breakthrough, researchers from North Carolina State University have discovered that materials derived from crustaceans and seaweed can play a crucial role in creating next-generation packaging films. This pioneering research has focused on combining chitosan, a biopolymer found in crab shells, and agarose, a biopolymer extracted from seaweed, to develop unique biopolymer composite films that possess enhanced strength, biodegradability, antibacterial properties, water-repellence, and transparency. These findings have the potential to revolutionize the packaging industry, leading to the development of sustainable films for food and consumer goods.

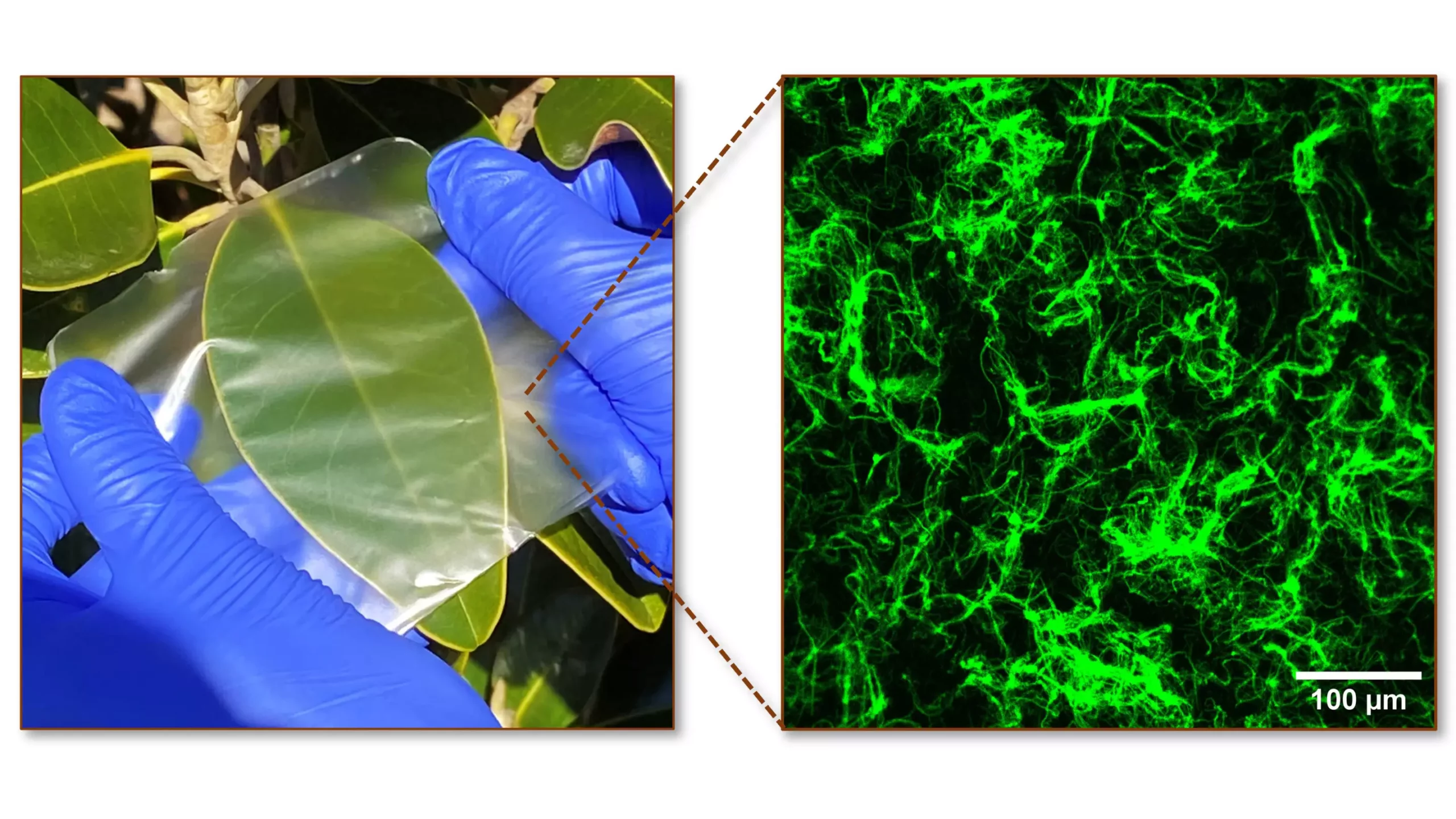

The blending of chitosan and agarose alone does not yield the desired results. Previous attempts to create such mixtures resulted in films with improved properties, but they often lacked the necessary strength. To overcome this challenge, the research team took a different approach and reinforced agarose films with fibrillated colloidal scale material, known as soft dendritic colloids, made from chitosan. The incorporation of chitosan micro- and nanoscale fibrils with hierarchically branched structures provided the necessary strength and stability to the agarose film.

When it comes to modifying natural polymers, such as chitosan and agarose, chemical alterations are often challenging. However, by altering their morphology and utilizing them as composites, researchers have successfully enhanced their properties. The compatibility of chitosan dendritic particles with agarose matrix plays a vital role in achieving desirable mechanical properties. Additionally, the opposite charge of chitosan particles to agarose allows for neutralization, resulting in improved resistance to water. This innovative approach has resulted in biopolymer composites that are about four times stronger than agarose films alone.

One of the remarkable properties of the biopolymer composites is their biodegradability, which sets them apart from traditional plastic films. The research shows that a sheet made from these composite films significantly degrades after a month underground. In contrast, a common plastic sandwich baggie remains intact under the same conditions. Initially, the biopolymer composites exhibit strong antibacterial properties. However, due to their natural composition, bacterial colonization occurs over time, resulting in biodegradation. This characteristic aligns with sustainable packaging practices that prioritize environmental impact.

Although the biopolymer composites have shown immense potential, further research is necessary to achieve properties comparable to synthetic polymer films. The research team acknowledges the importance of impermeability to oxygen and water for packaging applications. Natural materials inherently possess permeability, which calls for continuous efforts to enhance the impermeability of the films to meet industry standards. Future studies will focus on optimizing the structure of the biopolymer composite films to achieve the desired properties.

Apart from improving the properties of the biopolymer composites, another critical aspect is increasing the scalability of the production process. The researchers highlight the need for a continuous and rapid manufacturing process to meet the demands of large-scale production. Comparable to the process of papermaking, developing a seamless and efficient manufacturing process is crucial for advancing the commercial viability of these sustainable packaging films.

The research conducted by the team at North Carolina State University indicates a promising future for sustainable packaging. By harnessing the potential of materials derived from crustaceans and seaweed, biopolymer composite films are revolutionizing the industry. These films offer enhanced strength, biodegradability, antibacterial properties, water-repellence, and transparency. Continued research and development are necessary to achieve properties comparable to synthetic polymers and to improve the impermeability of the films. Moreover, scaling up the production process holds the key to making these innovative packaging films commercially viable on a large scale. With these advancements, a new era of sustainable packaging is on the horizon, bringing us closer to reducing our reliance on petroleum-based plastics and promoting a greener future.

Leave a Reply