Robotics systems have already made significant advancements in the industrial and manufacturing sectors, where they aid human workers in assembly line and warehouse operations. In recent years, researchers in the field of robotics and computer science have been working towards developing more advanced systems that can improve human-robot interactions in these settings. One such breakthrough is the introduction of a digital twin system by researchers at Nanjing University of Aeronautics and Astronautics in China. This system, outlined in their paper published in Robotics and Computer-Integrated Manufacturing, has the potential to revolutionize human-robot collaboration in manufacturing and industrial environments.

The current methods of constructing a human digital twin model in industrial settings often require personnel to wear motion capture devices. These devices are cumbersome and hinder the principle of flexible interaction advocated for human-robot collaboration (HRC). Additionally, these methods do not model humans and robots in a unified space, making it difficult to perceive and understand the overall environment. To address these limitations, the researchers propose a novel digital twin system for HRC.

The Digital Twin System

The digital twin system developed by Zhang, Ji, and their team creates a virtual replica of a scene where a human and robot agent collaborate. This virtual map of the real-world environment enables the system to plan and execute suitable robot behaviors that align with the human agent’s actions. Unlike previous digital twin systems that rely on motion capture sensors, this system takes into account occlusions, allowing for a more comprehensive understanding of the environment even when objects or agents are outside the sensors’ field of view or hidden behind obstacles.

Overcoming Obstacles with Innovative Techniques

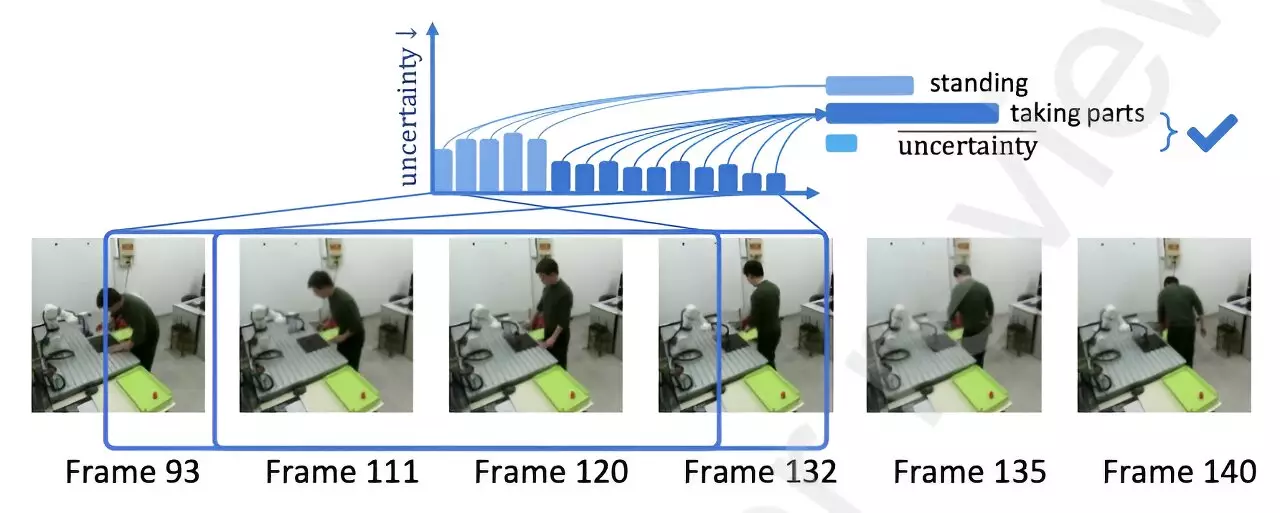

The researchers incorporated a human mesh recovery algorithm into their digital twin system to reconstruct occluded human bodies accurately. This computational technique complements the system’s ability to deliver precise collaborative strategies. Additionally, an uncertainty estimation technique was introduced to enhance the performance of the action recognition algorithm, mitigating the risk of errors. This algorithm is trained to recognize different human actions, further improving the overall system’s effectiveness.

The researchers conducted a series of experiments in laboratory settings using a robot designed for industrial deployment to assess the new digital twin system’s performance. The system demonstrated superior capabilities in enhancing collaboration between the robot and human agents across various tasks such as polishing, picking up objects, assembling, and placing down objects. The experiments highlighted the effectiveness of the proposed methods and validated the feasibility of the human-robot collaboration system through a case study involving component assembly.

Future Implications and Further Research

The digital twin system developed by Zhang, Ji, and their colleagues has significant potential for implementation in other industrial robots and further experimentation. The system’s ability to improve the collaboration between humans and robots in manufacturing and industrial tasks suggests a promising future application in real-world settings. Continued research and development in this area will contribute to the development of more advanced and efficient human-robot collaboration systems in industrial environments.

The innovative digital twin system introduced by the researchers at Nanjing University of Aeronautics and Astronautics offers exciting possibilities for enhancing human-robot collaboration in manufacturing. By addressing limitations of current methods and incorporating advanced techniques, this system demonstrates improved performance in a range of tasks. As this technology is implemented and tested further, it holds the potential to transform industrial environments and redefine the capabilities of human-robot collaboration.

Leave a Reply