The conductivity of metals has long been understood based on conventional wisdom. However, a recent discovery has defied these conventional notions, as materials scientist Keerti Kappagantula and her colleagues at the Pacific Northwest National Laboratory (PNNL) have found that graphene, a common carbon compound, can enhance an important property of metals called the temperature coefficient of resistance. This groundbreaking finding challenges the traditional understanding of how metals conduct electricity and opens up possibilities for improving electricity distribution and enhancing the performance of electric vehicles and industrial equipment.

The research team at PNNL used an advanced manufacturing platform called ShAPE to add 18 parts per million of graphene to electrical-grade copper. Surprisingly, this addition decreased the temperature coefficient of resistance by 11 percent without compromising electrical conductivity at room temperature. This is particularly significant for the manufacturing of electric vehicle motors, as even a 1 percent gain in motor efficiency can have a substantial impact. In contrast to the expected behavior, where additives increase the temperature coefficient of resistance, this research shows that graphene has the opposite effect, leading to increased conductivity in the manufactured copper wire.

To understand the mechanism behind this enhanced conductivity, the research team performed detailed structural and computational studies. The solid-phase processing used to extrude the composite wire creates a uniform, near pore-free microstructure with graphene flakes and clusters. It is believed that these flakes and clusters are responsible for decreasing the coefficient of resistance. The presence of both flakes and clusters seems to be essential for improving conductors for high-temperature operations. This discovery provides a new and exciting understanding of the behavior of metals when graphene is introduced.

The potential applications for the copper-graphene composite are vast. One significant area is in electric motors and generators, where coiled copper wire forms are used. The current limitations of operating within a specific temperature range may be overcome with this new composite, allowing for higher temperature operation without loss of conductivity. Additionally, the copper wiring used to bring electricity from transmission lines into homes and businesses could be made more conductive, meeting the increasing demand for power in high-density urban settings. Electrical transmission and distribution systems could become more efficient with the implementation of this technology.

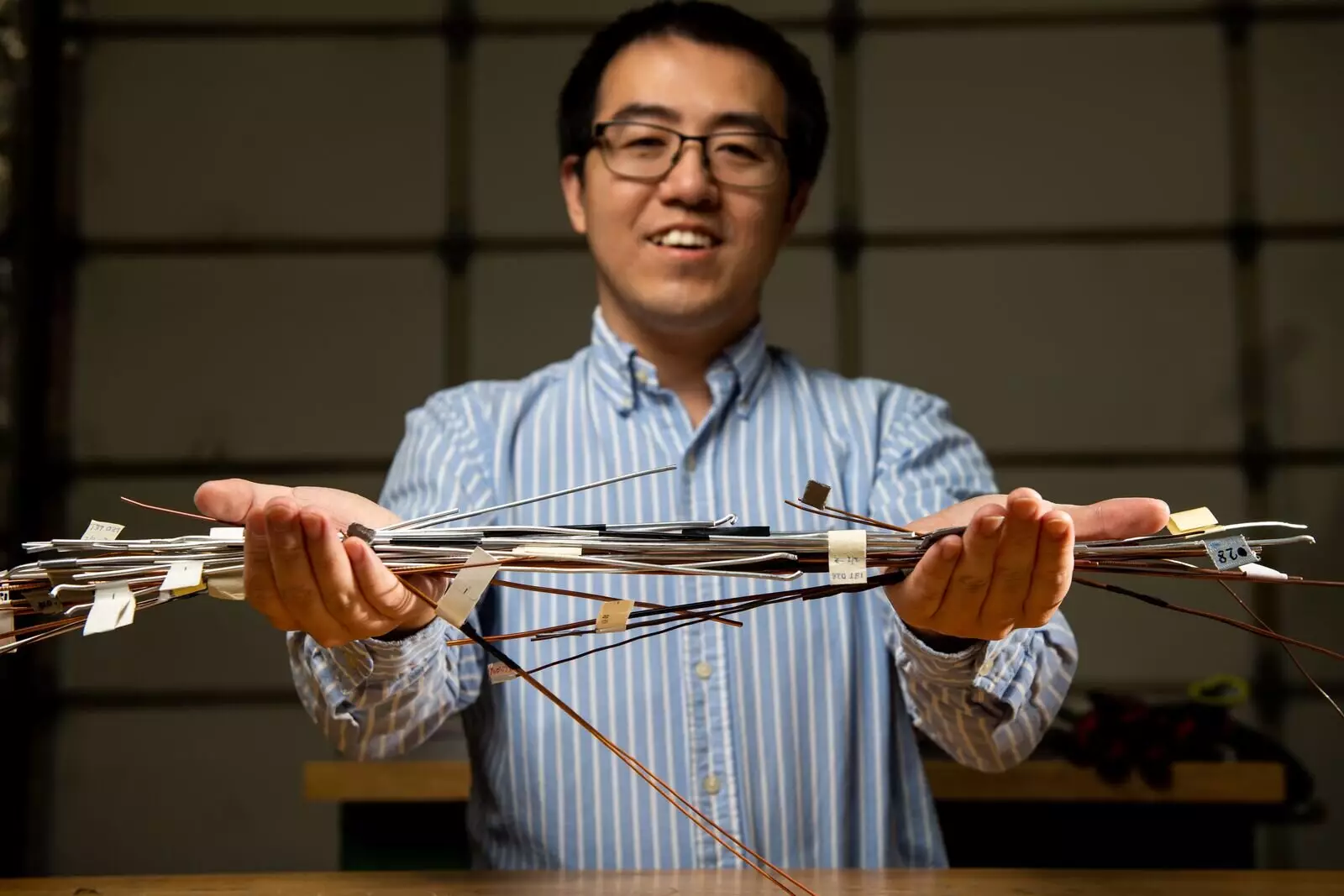

The research team at PNNL is continuing their work to further customize the copper-graphene material and measure other essential properties such as strength, fatigue, corrosion, and wear resistance. These properties are crucial for qualifying the material for various industrial applications. With ongoing experiments on wires about the thickness of a US penny, the team aims to ensure that the composite meets the necessary criteria for widespread use in different sectors.

The discovery of the role of graphene in enhancing electrical wires has opened up a world of possibilities. This breakthrough challenges long-held beliefs about metal conductivity and offers opportunities for improvements in electricity distribution, electric vehicle efficiency, and industrial equipment performance. As the research team at PNNL continues to fine-tune the copper-graphene composite and explore its properties, the future looks promising for a new generation of highly conductive materials. With the potential for enhanced efficiency and cost savings, the integration of graphene into copper wires represents a significant advancement in the field of electrical engineering.

Leave a Reply