In a groundbreaking study, a team of chemical engineers and materials scientists at Zhejiang University in China has made a remarkable discovery – a new type of aerogel fiber that surpasses the warmth of traditional down when woven into a sweater. Published in the prestigious journal Science, their research outlines the inspiration behind their groundbreaking fibers, the innovative production process, and the exceptional performance observed in cold environments. This monumental breakthrough has the potential to revolutionize the textile industry and redefine our understanding of warmth and durability.

Aerogels, an innovation dating back to the 1930s, have captivated scientists due to their exceptional thermal properties. These unique materials are gels in which the liquid component is replaced with air, resulting in a substance with remarkable insulating capabilities. NASA space vehicles have leveraged the properties of aerogels, highlighting their immense value as an insulating material in extreme conditions. Consequently, materials scientists have long sought to harness the potential of aerogels to develop warm textiles. However, their efforts have been impeded by challenges related to moisture permeability and strength.

In their quest to overcome these obstacles, the Chinese research team embarked on an ambitious journey to replicate the thermal properties of polar bear fur. They recognized that the dense shell and porous core of the fur’s hairs enable these resilient creatures to withstand freezing temperatures. Drawing inspiration from nature, the team developed an encapsulated aerogel fiber by initiating a sol-gel transition with a frozen precursor. Subsequently, through a meticulous freeze-drying process and the application of a semi-hard shell, the team successfully created thin, round fibers with customizable lengths. Most intriguingly, no post-processing was necessary to produce textiles, making the production of these innovative fibers a more cost-effective option compared to existing alternatives.

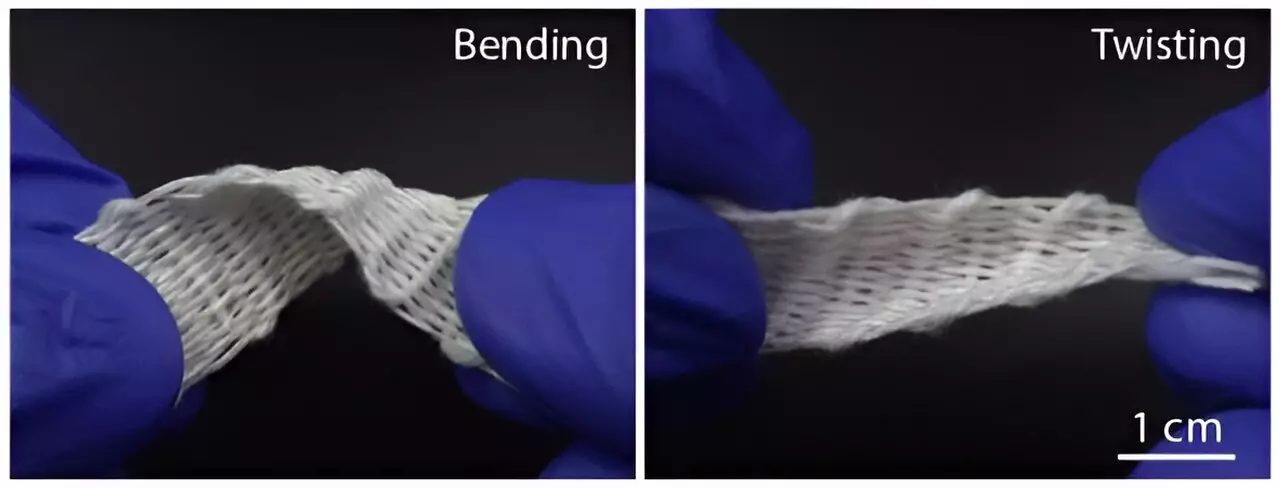

Building on their groundbreaking work, the researchers produced batches of their fibers in long strands, which were then expertly woven into a sweater. Testing the limits of their creation, the team exposed the sweater to bone-chilling temperatures as low as -20°C. The findings were astounding – the aerogel fiber-infused sweater demonstrated superior thermal protection when compared to traditional sweaters made from down, wool, or cotton. Even after subjecting the sweater to 10,000 stretching cycles, it remained remarkably robust with minimal damage. The remarkable properties of these fibers extend beyond their insulation capabilities – they possess the unique ability to be stretched, dyed, and flexed, making them an incredibly versatile material for textile applications.

The advent of aerogel fibers represents a monumental advancement in the textile industry. With their superior warmth and durability, these fibers possess the potential to redefine our expectations of winter clothing. Beyond sweaters, the applications for aerogel fiber textiles are limitless – coats, gloves, and hats infused with this revolutionary material could offer unparalleled protection against the harshest of environments. Moreover, the cost-effective production process of these fibers ensures that warmth, comfort, and functionality need not come at an exorbitant price. As researchers continue to unlock the full potential of aerogel fibers, the future of innovative and high-performance textiles looks exceptionally promising.

The breakthrough achieved by the team of chemical engineers and materials scientists at Zhejiang University in China represents a significant milestone in the quest for warmer and more durable textiles. Inspired by the thermal properties of polar bear fur, they successfully developed encapsulated aerogel fibers that outperform traditional materials in terms of warmth and resilience. This ground-breaking innovation not only paves the way for a new generation of winter clothing but also redefines our understanding of what is possible in the field of materials science. As we stand on the cusp of a new era in textile engineering, the rise of aerogel fibers promises a future where warmth, durability, and versatility coexist harmoniously.

Leave a Reply