Plastic has long been a cause for concern due to its detrimental impact on the environment and human health. From its pervasive presence in soil and oceans to the discovery of microplastics in the human body, the urgent need to reduce plastic usage has become increasingly evident. In response to this global challenge, a team of molecular engineers from the University of Chicago, in collaboration with colleagues from the US DEVCOM Army Research Laboratory, Aberdeen Proving Ground, the National Institutes of Standards and Technology, and the NASA Glenn Research Center, have spearheaded a groundbreaking innovation – a shape-shifting plastic that can be transformed through tempering.

To achieve the malleability required for shape-shifting, the research team developed a unique plastic using a dynamic cross-linked approach. This approach is grounded in the reversible addition of thiols to benzalcyanoacetates, otherwise known as a “Michael addition.” Through this composition, the plastic possesses the ability to be modified through the process of tempering – a technique commonly associated with metalwork.

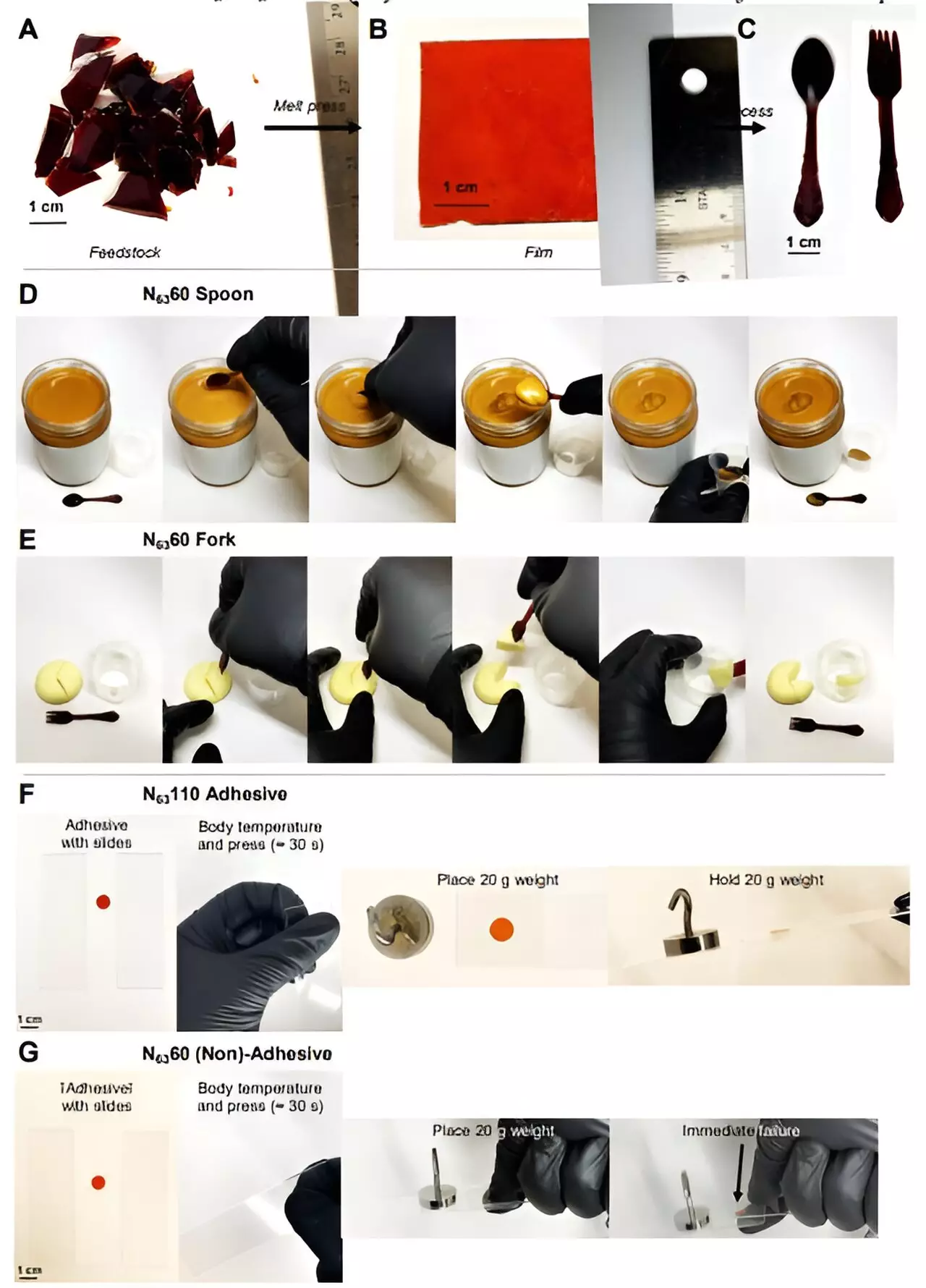

The process of tempering involves subjecting a material to specific temperature conditions before rapidly cooling it. In the case of this shape-shifting plastic, the researchers discovered that by heating it to temperatures ranging between 60°C and 110°C and subsequently transferring it to a standard food freezer, they could mold it into various forms. The plastic sample underwent a metamorphosis, transforming from a spoon to a fork to an adhesive substance capable of bonding two glass panes together.

Despite its groundbreaking potential, this shape-shifting plastic does face certain limitations. After undergoing numerous transformations, the plastic starts to degrade, rendering it less efficient and structurally compromised. Extensive testing revealed that the maximum number of transformations achievable was seven, beyond which the material’s integrity was compromised.

While this new innovation in plastics offers tantalizing possibilities for a more sustainable future, it is crucial for further research and development to address the limitations found in the shape-shifting plastic. By delving into the underlying factors that cause degradation after a certain number of transformations, the durability and longevity of such materials can be significantly enhanced. This breakthrough is undeniably an important step towards reducing plastic waste and promoting a circular economy – one in which plastic products can be repurposed and reinvented rather than discarded.

This remarkable discovery signals a potential revolution in the world of plastic. Imagine the possibilities in reducing plastic waste if everyday items, such as food bags, could be easily transformed into reusable utensils or functional objects. By harnessing the power of tempering, we can unleash the true potential of plastic as a versatile and sustainable material.

The team of molecular engineers at the University of Chicago, in collaboration with esteemed institutions, has unlocked a new era for plastic with their shape-shifting innovation. Through the clever use of tempering and a dynamic cross-linked approach, they have created a plastic capable of multiple transformations. While limitations exist, this breakthrough paves the way for a more sustainable future, where plastic products can be effectively repurposed and contribute to a circular economy. As we continue to confront the challenges posed by plastic waste, this remarkable invention offers hope and inspiration for a cleaner and greener world.

Leave a Reply