The world of automotive technology is rapidly evolving, with modern cars now being filled with a plethora of electronics and assistance systems. However, managing these complex systems poses a significant challenge, as the weight of the car continues to increase due to the sheer number of cable harnesses required. In response to this, Fraunhofer researchers have embarked on a groundbreaking research project known as CeCaS. The primary aim of this project is to develop a revolutionary systems architecture that centralizes the management of all electronic components from a single supercomputing platform. This paradigm shift will simplify the construction of highly automated and connected vehicles, ushering in a new era of automotive innovation.

Real-Time Ethernet Backbone

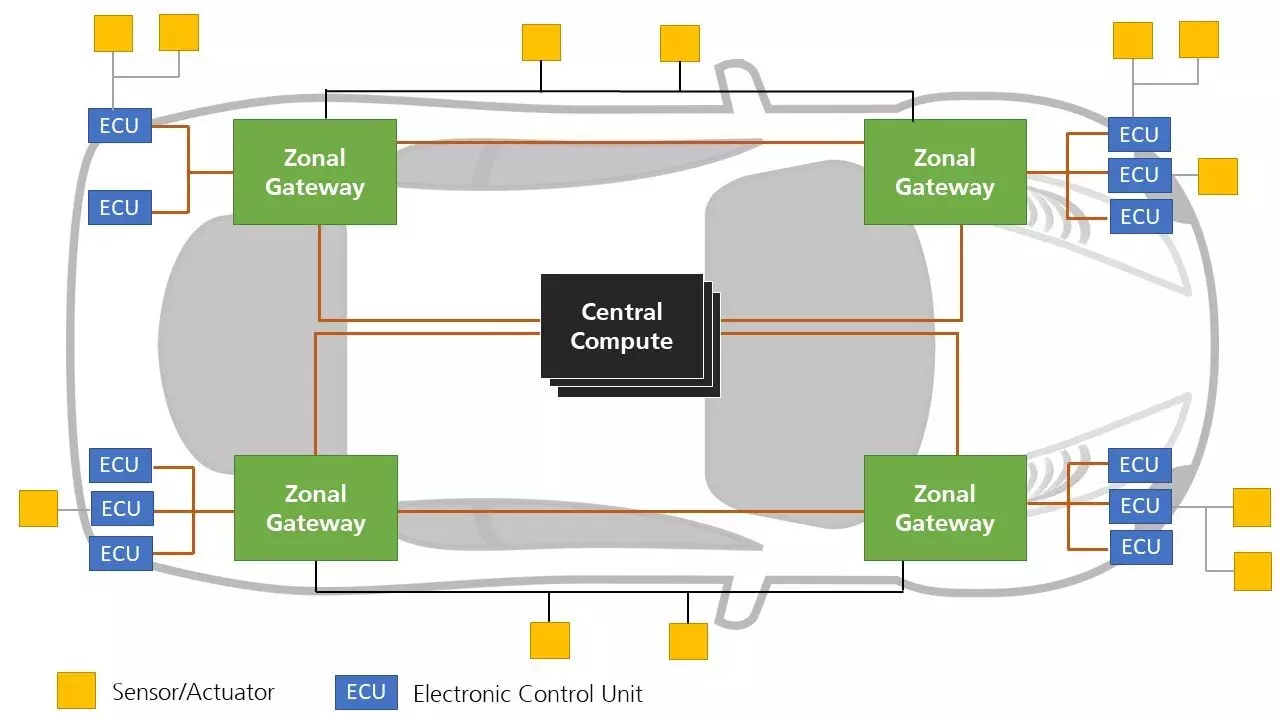

One of the key components of the Fraunhofer technology being developed is an incredibly reliable Ethernet backbone that operates in real-time. This innovative approach envisions a future where cars are controlled from a central supercomputing platform, as opposed to the current intricate web of interconnected computer systems. Imagine being able to update your vehicle wirelessly via Wi-Fi, without the need for a trip to the mechanic. Moreover, with this centralized approach, new functionalities can easily be integrated as needed, providing unparalleled flexibility and adaptability in the automotive industry.

The CeCaS project has garnered support from the German federal government, underlining the urgent need for a new computer architecture in cars. With trends such as automation and connectedness driving the demand for increased data volumes in vehicles, manufacturers are actively seeking solutions to streamline vehicle technologies, centralize component management, optimize system communication, and provide high-speed computing capabilities in real-time. The collaboration between the Fraunhofer Institute for Photonic Microsystems IPMS and partners from the automotive industry underscores the importance of interdisciplinary cooperation in driving technological advancements in the automotive sector.

The Dresden-based Fraunhofer researchers are focusing on Time-Sensitive Networking (TSN) as a core technology for the CeCaS project. By enhancing their existing IP cores with TSN capabilities, the team aims to imbue Ethernet-based network technology with real-time capabilities, ensuring robustness and reliability in all operating conditions. Dr. Frank Deicke, head of Data Communication and Computing, emphasizes the importance of TSN in achieving real-time performance and reliability through advanced system time synchronization, smart process queue management, and task prioritization. This ensures that critical commands, such as those related to the brake system, take precedence over less urgent tasks like adjusting the air conditioning.

Advantages of Centralized Architecture

The benefits of the centralized architecture model being developed in the CeCaS project extend beyond real-time communication and system reliability. The ability to update vehicles wirelessly via Wi-Fi, similar to updating a laptop or desktop PC, opens up a world of possibilities for seamless integration of new functionalities. Additionally, the streamlined central control system reduces the need for extensive cable harnesses, resulting in cost savings and a lighter overall vehicle. Dr. Deicke further highlights the scalability and adaptability of Ethernet technology, particularly when combined with Fraunhofer’s IP cores, allowing for easy customization across different vehicle sizes, performance categories, and functions.

The ambitious computer architecture developed in the CeCaS project represents a fundamental shift in conventional construction methods for cars. Moving from domain-based control of components to zone-based management, the new approach enables a few high-performance computing platforms to oversee numerous modules simultaneously. This holistic approach covers a wide range of systems, including safety-critical components like the engine, gearbox, and brakes, as well as various sensors, motors, climate control systems, and entertainment features. By centralizing control and adopting a zone-based management strategy, the automotive industry is poised to enter a new era of innovation and efficiency.

Leave a Reply