Ceramic materials have long been utilized in various industrial applications due to their mechanical strength, chemical inertness, and ability to withstand high temperatures. However, their inherent brittleness has limited their use in certain scenarios where plastic deformability is required. Researchers in Purdue University’s College of Engineering have made significant strides in overcoming this limitation by developing a groundbreaking method to enhance the plasticity of ceramics at room temperature.

Haiyan Wang and Xinghang Zhang, along with their team at Purdue University, have devised a patent-pending technique to introduce high-density defects in brittle ceramics under elevated temperatures. This method aims to increase the plastic deformability of ceramics, ultimately imparting ductility – the ability to be shaped without breaking – to these traditionally brittle materials. By preloading ceramic samples with dislocations at high temperatures and then cooling them, the researchers have successfully improved the plasticity of ceramics at room temperature.

The research conducted by Wang, Zhang, and their team has the potential to revolutionize the industrial applications of ceramics. With enhanced plastic deformability, ceramics can be utilized in a wider range of industries, including aerospace, transportation, power generation, and manufacturing. The ability to draw ceramics into near-net shapes opens up new possibilities for their use in bearings, capacitors, electrodes, and thermal barrier coatings, among other applications.

Despite the numerous advantages of ceramic materials, their brittleness at room temperature has always posed a challenge. Wang attributes this brittleness to the lack of dislocations within ceramics, which hinder their ability to deform plastically. In contrast to metals, which readily nucleate dislocations and exhibit ductility, ceramics require a different approach to enhance their plasticity.

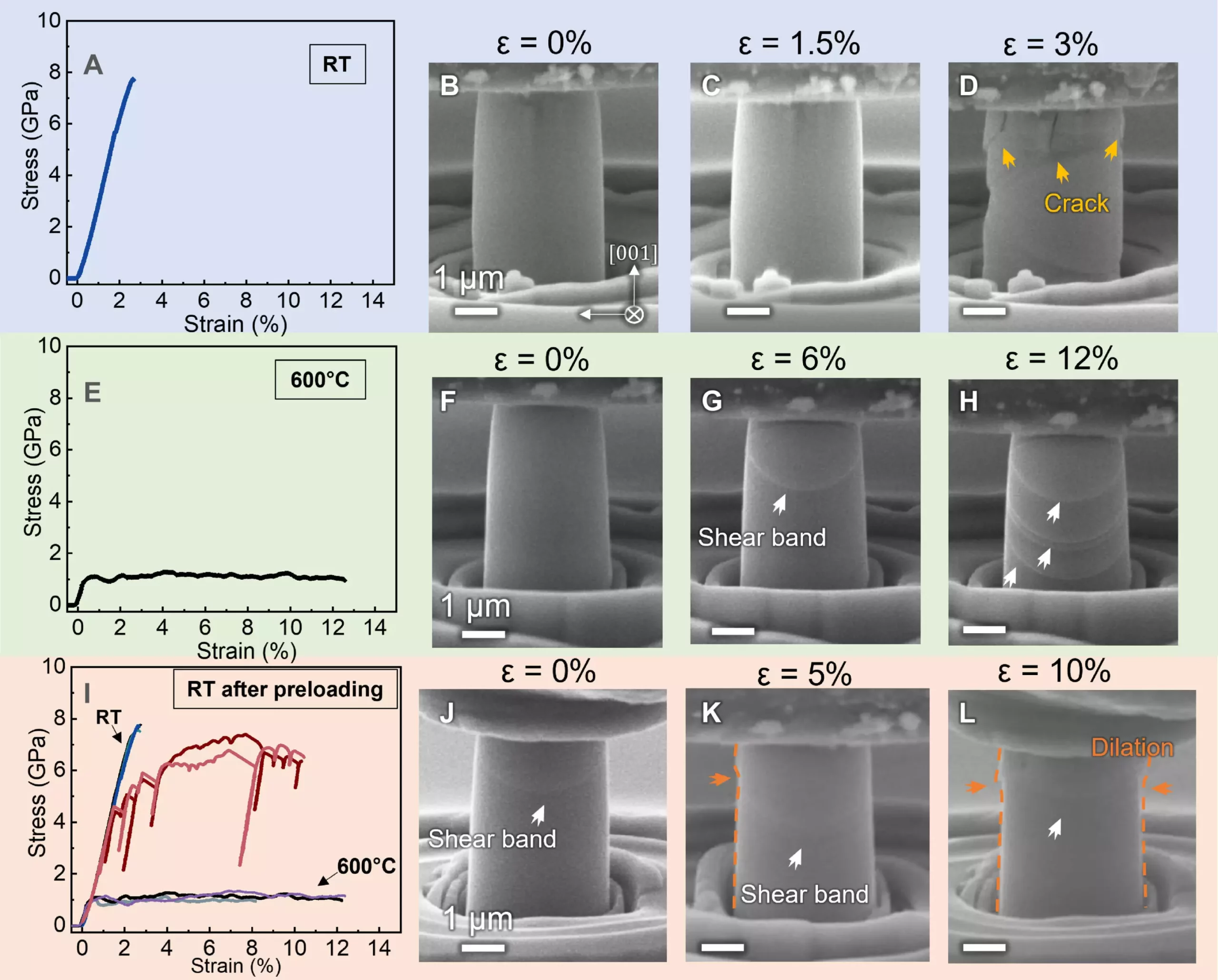

By introducing dislocations through a preloading technique, Wang, Zhang, and their team have successfully increased the plastic deformability of ceramic materials. This method, which is more universally applicable than previous techniques such as flash sintering, has shown promising results in various ceramic systems. Notably, single-crystal titanium dioxide and aluminum oxide have exhibited significant improvements in plasticity, achieving strains of 10% and 6-7.5%, respectively, at room temperature.

The innovative approach developed by the Purdue University researchers has the potential to reshape the field of ceramic materials. Collaborations with industry partners for large-scale demonstrations will further validate the effectiveness and scalability of this method. Additionally, the filing of a patent application underscores the commercial potential of this groundbreaking innovation, signaling a new era for the mechanical properties of ceramics.

The research conducted by Wang, Zhang, and their team represents a significant advancement in the field of ceramic materials. By enhancing the plastic deformability of ceramics at room temperature, this innovative method opens up new possibilities for the industrial applications of these materials. With further development and collaboration, the potential for ceramics to exhibit ductility and pliability comparable to metals may soon become a reality.

Leave a Reply