Biological systems have long been an inspiration for scientists and engineers alike, particularly when it comes to the development of materials that combine strength with flexibility. Nature’s craftsmanship is exemplified in structures like sea sponges, which utilize a layer-based growth process to form unique, robust architectures. These sponges integrate mineral compositions with softer organic components, highlighting a remarkable ability to balance diverse material characteristics. As highlighted by Nancy Sottos from the Beckman Institute for Advanced Science and Technology, nature excels in producing durable materials that can withstand strain while remaining resilient.

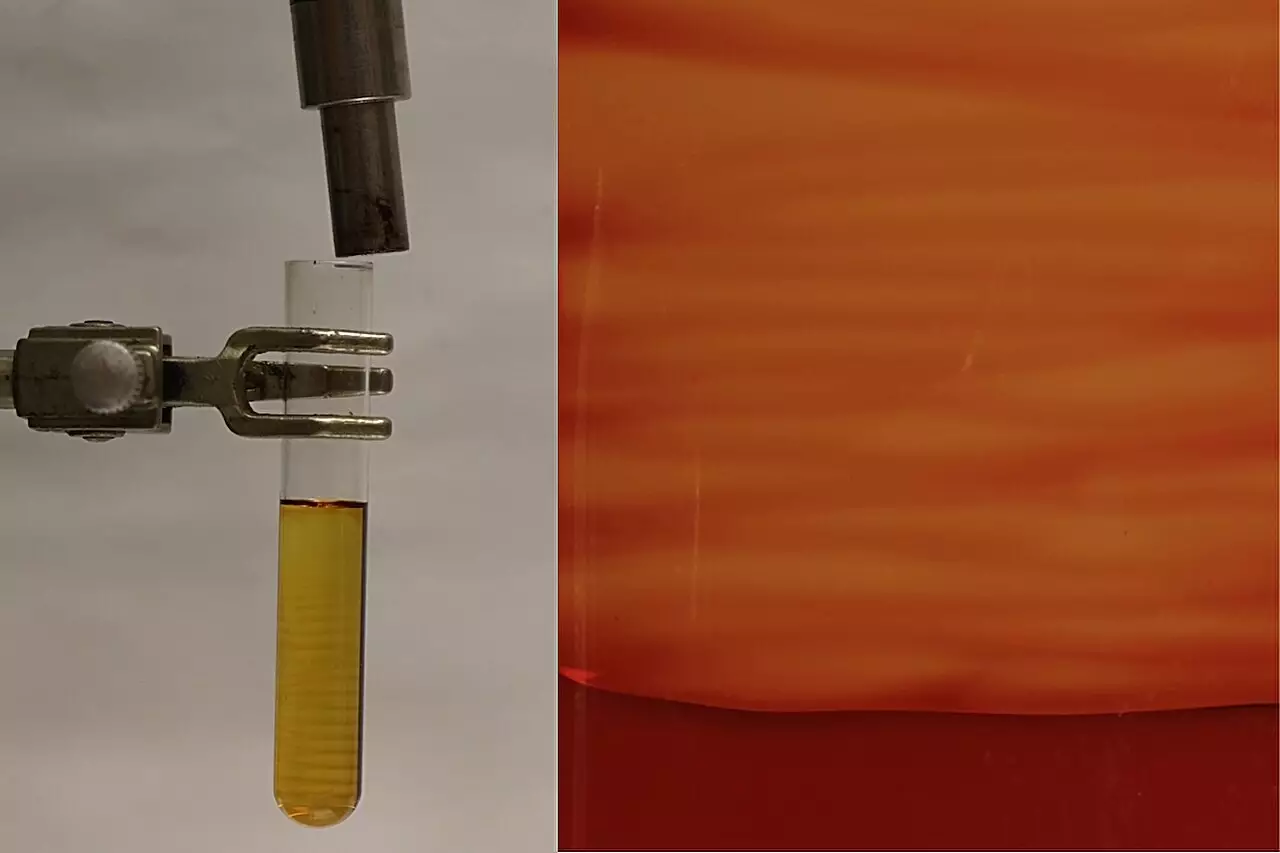

Recent advances in materials science have introduced innovative synthetic approaches that emulate nature’s mechanisms. Sottos and her team have focused on a technique known as frontal polymerization, which leverages heat to catalyze polymer formation. This method presents a significant stride in the field, promising new avenues for creating materials that mirror the adaptability seen in natural structures. Following a 2021 breakthrough that validated frontal polymerization as a viable method for developing biologically inspired polymers, the team has now expanded upon this by refining the process to enable controlled crystallization within the materials.

The ability to conduct precise alterations in chemical reactions presents exciting possibilities in material design. By harnessing a concept known as morphogenic manufacturing, Sottos’ team has successfully achieved intricate crystalline patterns within the polymers. This accomplishment is not simply about replicating nature’s designs; it involves understanding the underlying mechanisms that dictate material properties. Lead author Justine Paul revealed that optimizing the reaction conditions necessitated a detailed investigation over several weeks, with the ultimate goal of observing dynamic behaviors crucial for producing materials with enhanced toughness.

An essential element of this research was the collaboration among diverse fields, merging expertise in chemistry, engineering, and physics. Cecilia Leal’s contributions employed X-ray scattering techniques to study how polymer chains orient themselves in the new patterned material. This research underscores the significance of a comprehensive approach to understanding the interplay between a material’s structure and its properties. This interdisciplinary perspective has led to significant insights that would be unattainable in a confined research environment.

Aerospace engineering professor Philippe Geubelle’s focus on modeling was vital for capturing the thermo-chemical instabilities associated with manufacturing these heterogeneous materials. Modeling enables researchers to anticipate the properties and behaviors of materials before physical prototypes are developed. By simulating various conditions and outcomes, the team could optimize their process and push the boundaries of what synthetic materials can achieve.

The triumph of this project is a testament to the power of interdisciplinary collaboration. As articulated by Jeff Moore, the integration of experimental research with theoretical modeling has been instrumental in achieving the reported breakthroughs. The research group, part of the Autonomous Materials Systems Working Group at the Beckman Institute, represents a confluence of ideas where different fields converge, resulting in innovative techniques that push the envelope of current material science.

As researchers continue to uncover the intricacies of nature-inspired design, the implications of such breakthroughs are profound. The capabilities to generate patterned materials through innovative processes such as frontal polymerization not only enhance durability and strength but also open new avenues for applications across industries from aerospace to biomedical devices. By bridging the gap between organic and synthetic materials, the potential to design products that mimic the resilience of natural systems is an exciting frontier in material science—one that may redefine how we fabricate essential technologies in the future.

Leave a Reply