In the realm of advanced ultrasonic and sonar technologies, piezoelectric materials are essential for their capability to generate and sense waves effectively. However, these materials can suffer from degradation due to heat and pressure, which jeopardizes their efficient operation. Traditionally, rectifying damage involves disassembling devices and exposing the materials to high temperatures, often around 300°C or more. This process is not only labor-intensive but can also lead to the waste of expensive materials when the entire device is discarded instead of just the damaged components. This article delves into recent advancements that promise to ease these challenges, focusing on a groundbreaking room temperature technique to restore the essential properties of piezoelectric materials without the need for disassembly or excessive heat.

To appreciate the significance of this new technique, one must first understand how piezoelectric materials work. These materials are primarily ferroelectric, which means they exhibit spontaneous polarization. They contain dipoles, which are pairs of charged ions that need to be aligned to maximize their piezoelectric effects. When a piezoelectric material is ‘poled,’ the dipoles are aligned along an electric field, enhancing their efficiency in generating targeted ultrasound waves. However, factors such as temperature, pressure, or even prolonged usage can cause these dipoles to lose their alignment, resulting in diminished performance.

Xiaoning Jiang, a notable researcher in this field, emphasizes that maintaining this alignment is crucial for function. For instance, slight temperature increases of just 70°C can initiate alignment problems, adversely affecting the effectiveness of ultrasound devices. Consequently, manufacturers have faced limitations when introducing new materials and processes that could otherwise enhance production and efficiency.

In what could be a game-changer for the industry, researchers have unveiled a technique allowing the de-poling and re-poling of piezoelectric and ferroelectric materials at room temperature. This breakthrough means that it is now possible to realign the dipoles without dismantling the device or exposing the materials to extreme heat. The findings were published in the journal *Nature Communications,* highlighting the implications for future ultrasound technologies and manufacturing processes.

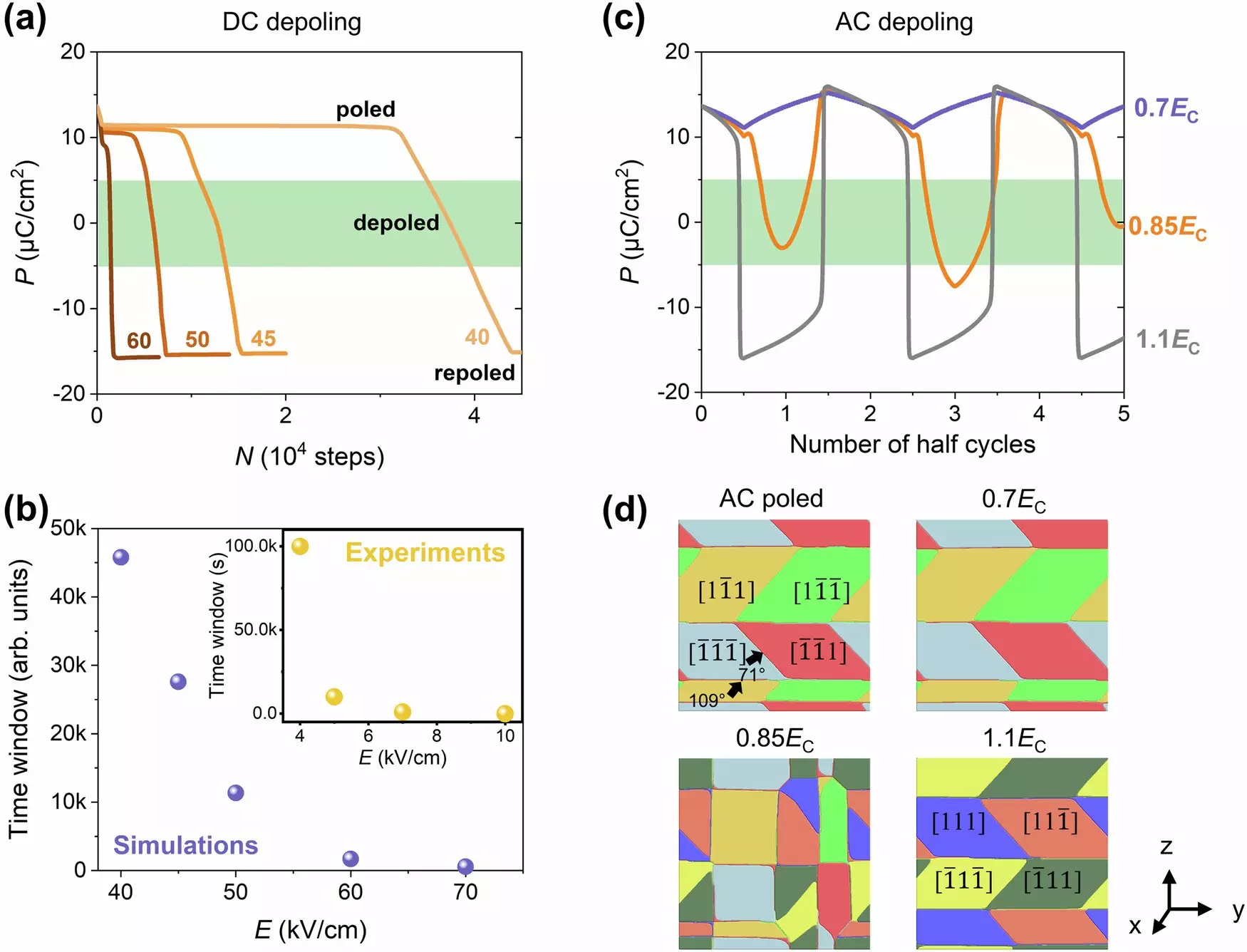

The traditional method for aligning dipoles typically involves applying a direct current (DC) electric field, which effectively pulls dipoles into alignment. However, this technique lacks the ability to depole material merely by using a DC field. Researchers discovered that by employing an alternating current (AC) electric field, they could facilitate oscillation in the dipoles, enabling complete depoling when needed—especially if the material had initially been poled with an AC application. This new approach allows for continual adjustment of piezoelectric materials, paving the way for more durable and repairable devices.

This innovative technique has far-reaching implications for both the manufacturing processes of ultrasonic devices and their practical applications. By eliminating the need for high heat, manufacturers can explore different materials and methods that were previously avoided due to concerns over their effects on polarization. Since the new method operates effectively at room temperature, device longevity is extended, facilitating repeated operations without the risk of damaging the piezoelectric material.

Furthermore, minimizing the risk of damage during transportation or storage is another advantage. With traditional methodologies, even shipping these technologies could result in misaligned dipoles, rendering devices less effective or inoperable. The room temperature technique opens doors to enhanced reliability during transport and storage, ensuring devices remain in peak condition.

The development of a room temperature technique for de-poling and re-poling piezoelectric materials signifies a monumental leap toward more efficient and sustainable ultrasound and sonar technologies. By simplifying the repair process, manufacturers can maintain the integrity of expensive materials and keep devices operational without extensive overhauls. This breakthrough might not only extend the lifecycle of existing technology but also foster innovation and diversification in the field. As we move forward, this approach could redefine how we engineer and interact with devices that rely on the remarkable properties of piezoelectric materials, leading to a new era of advancements in technology.

Leave a Reply