Electric vehicles (EVs) are rapidly gaining traction within the automotive industry, necessitating a concurrent evolution in battery technology. At the heart of this transformation lies the quest for innovative energy storage solutions that enhance the operational duration and efficiency of these vehicles. A pioneering concept emerging in this domain is that of structural batteries. Unlike conventional batteries, which are external components, structural batteries integrate energy storage capabilities directly within the vehicle’s framework, consequently fulfilling dual roles—both as structural elements and energy reservoirs.

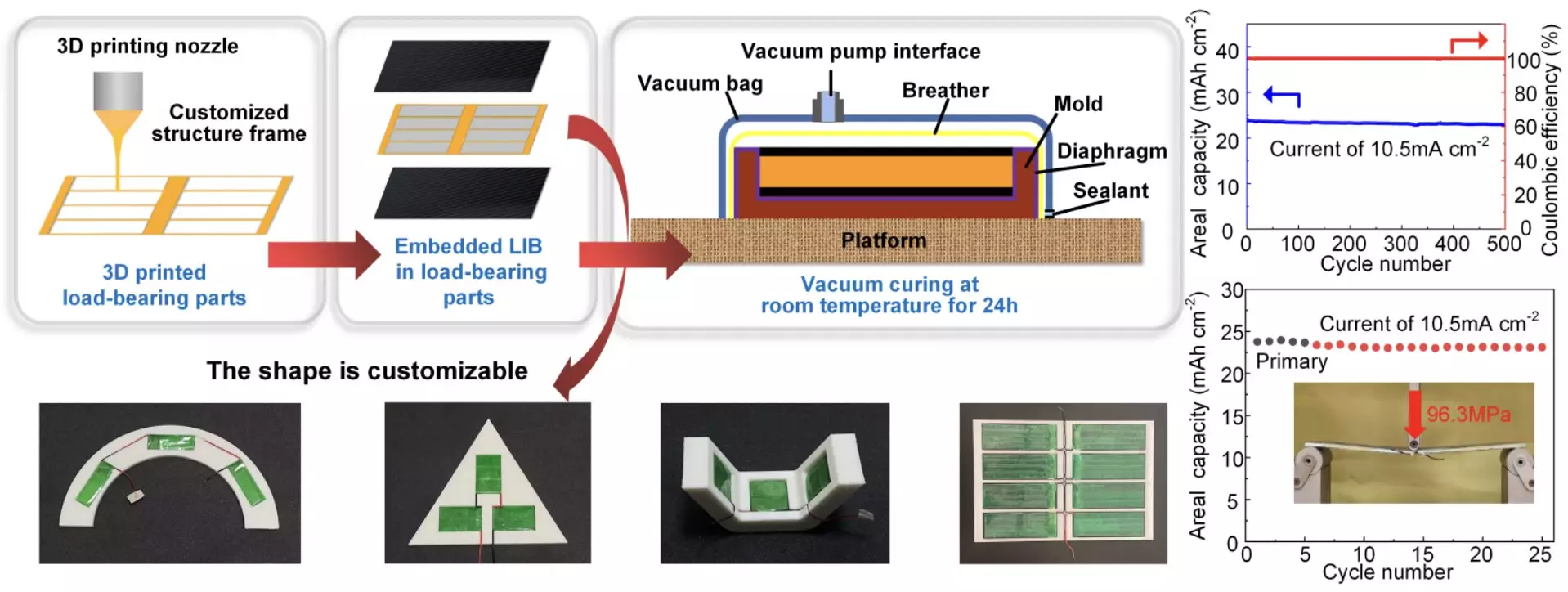

Structural batteries are a groundbreaking development in materials engineering, merging the functions of traditional batteries with structural components. This integration allows for a more compact design, potentially reducing the vehicle’s weight while also increasing energy storage. Researchers from Shanghai University, among others, are at the forefront of this innovation, focusing on the fabrication of lithium-ion structural batteries using advanced techniques such as 3D printing. The innovative manufacturing process not only allows for custom geometric configurations but also optimizes the performance characteristics essential for sustained use in demanding environments like EVs.

Yinhua Bao, a leading researcher in this area, emphasizes that the goal of their work is to develop an integrated system that combines load-bearing strength with high energy density. This ambitious venture addresses significant challenges in battery technology—namely, the need for materials that can sustain mechanical stresses without sacrificing energy output.

Despite the promise shown by structural batteries, earlier models have encountered considerable challenges. Many of these innovations have faltered due to issues such as low energy density and inadequate electro-mechanical performance. In response, Bao and his team have taken a systematic approach to overcome these limitations. Through their research, they aim to create solutions that significantly enhance the mechanical stability of batteries while maintaining high energy output. Their exploration of 3D printing as a fabrication method is a critical step in achieving this aim.

The notion of a decoupled structure is particularly significant in their design. By ensuring that the energy storage unit is independent of the structural framework, the design minimizes the risk of damage when subjected to mechanical stress. This innovative approach not only fosters durability but also enhances the overall cycle life of the batteries, a critical factor for practical implementation in various applications.

The incorporation of 3D printing technology into the manufacturing of structural batteries marks a significant evolution in the battery production landscape. Its adaptability enables researchers to experiment with varied configurations and materials rapidly, adjusting design parameters to meet specific performance criteria. This method facilitates a level of customization that is difficult to achieve with traditional manufacturing techniques, allowing for precise control over structural integrity and energy storage capacities.

In experimental settings, Bao and his team demonstrated that their novel composite structural battery could withstand significant tensile and bending stresses while retaining a high energy density—recording performance metrics of 120 Wh kg-1 and 210 Wh L-1. These results underscore the viability of 3D-printed batteries not just for electric vehicles but potentially for other engineering applications including robotics and autonomous systems.

The future applications of structural batteries are expansive, with implications extending beyond the automotive industry. As Bao noted, this technology has potential uses in the design of batteries for unmanned aerial vehicles (UAVs), robotic vehicles for logistics, and even in portable electronic devices. The ability to produce high-capacity batteries that are both lightweight and efficient could revolutionize energy storage across various sectors.

Looking ahead, the journey towards widespread adoption of structural batteries will involve continued research and development. Future initiatives may focus on exploring diverse materials to enhance performance further and utilize finite element simulations to optimize designs for specific operational contexts. This proactive approach to materials science will be crucial in addressing the specific demands of different applications, paving the way for structural batteries to become a cornerstone in the next generation of energy storage technologies.

The prospects for structural batteries are promising and indicative of a broader shift toward innovative energy storage solutions. As research progresses, these batteries could not only enhance the performance of electric vehicles but also contribute to the burgeoning fields of robotics and smart technologies, marking a pivotal moment in our quest for sustainable energy solutions.

Leave a Reply