Catalysts are crucial to the chemical industry, influencing over 90% of the chemical products consumed in our daily routines. These substances facilitate and accelerate chemical reactions, enabling processes that would either take too long or require such high energy input that they would be impractical. Without catalysts, many of the modern materials and chemicals we take for granted would not exist. Thus, the push for more efficient, sustainable, and cost-effective catalytic processes is paramount, especially in light of rising resource constraints.

New Developments from Karlsruhe Institute of Technology

Researchers at the Karlsruhe Institute of Technology (KIT) have made significant strides in addressing these challenges, particularly concerning noble-metal catalysts. These materials, while effective, come with a steep resource cost; their scarcity and high price warrant an urgent need for solutions that can enhance their performance while reducing the amount needed. The team’s findings, now published in the journal Angewandte Chemie, offer exciting prospects for the future of catalysis. According to Dr. Daria Gashnikova, the lead author on the study, the innovative approach taken by the researchers promises not just to extend the lifespan of these catalysts but also to ensure the creation of active noble-metal clusters with far less material.

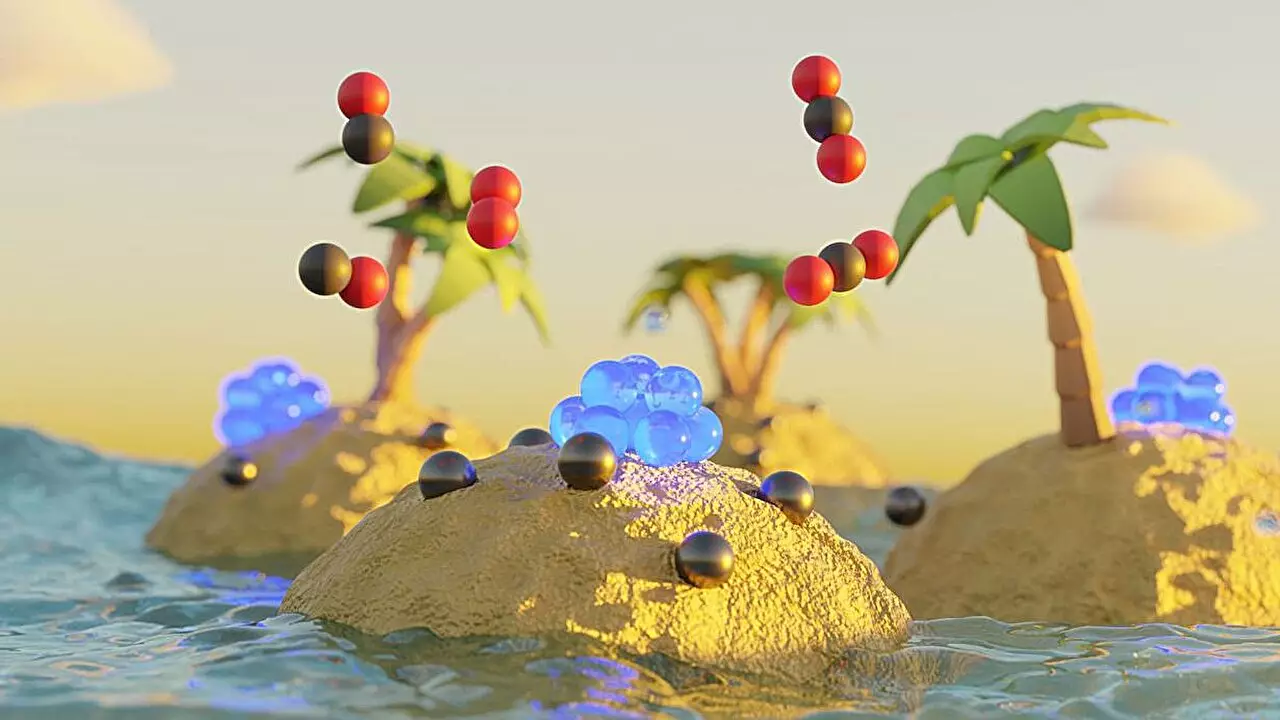

The groundwork for this advancement lies in a meticulous analysis of supported catalysts, where the reactive noble-metal components are dispersed as nanoparticles across a supportive substrate. This setup is designed to maximize catalytic reaction surfaces. However, these nanoparticle clusters are inherently unstable; they can merge or grow into larger structures, diminishing their effectiveness by reducing the number of accessible surface atoms involved in reactions. Conversely, they can disintegrate into ineffective single atoms, further hindering catalytic performance.

This duality poses a critical challenge: maintaining optimal stability while also facilitating maximum reactivity. The KIT researchers have ingeniously tackled this issue by enhancing the interactions between noble metals and their support materials, thereby increasing the stability of these dynamic nanoparticles.

The implications of such a discovery extend far beyond mere academic interest; they signal a pivotal shift towards more sustainable practices in chemical production. The reduced necessity for precious noble metals aligns with a broader ethos in industry toward resource conservation. In an age where environmental concerns and sustainability are paramount, the opportunity to lessen reliance on rare materials not only helps in curbing costs but also promotes a more eco-friendly chemical process.

It remains evident that the future of catalysis lies in continuously refining these processes, searching for ways to enhance efficiency and strengthen the stability of catalytic materials. The work being done at KIT exemplifies this pursuit, promising innovations that could revolutionize chemical manufacturing and enable a more sustainable future across multiple industries. As these findings pave the way for new research and technology developments, the quest for optimal catalysis continues, with the potential to reshape our relationship with chemical resources.

Leave a Reply