In an era where technology increasingly intertwines with biology, researchers are embarking on groundbreaking endeavors to develop smart materials that can replicate natural movements through innovative mechanisms. One remarkable advancement comes from a collaborative effort to embed gold nanorods in hydrogels, unlocking a new world of possibilities in design and function. This ingenious approach provides a pathway to create 3D-printed structures that can contract and expand in response to light, setting the stage for applications that could reshape numerous industries, from biomedical devices to soft robotics.

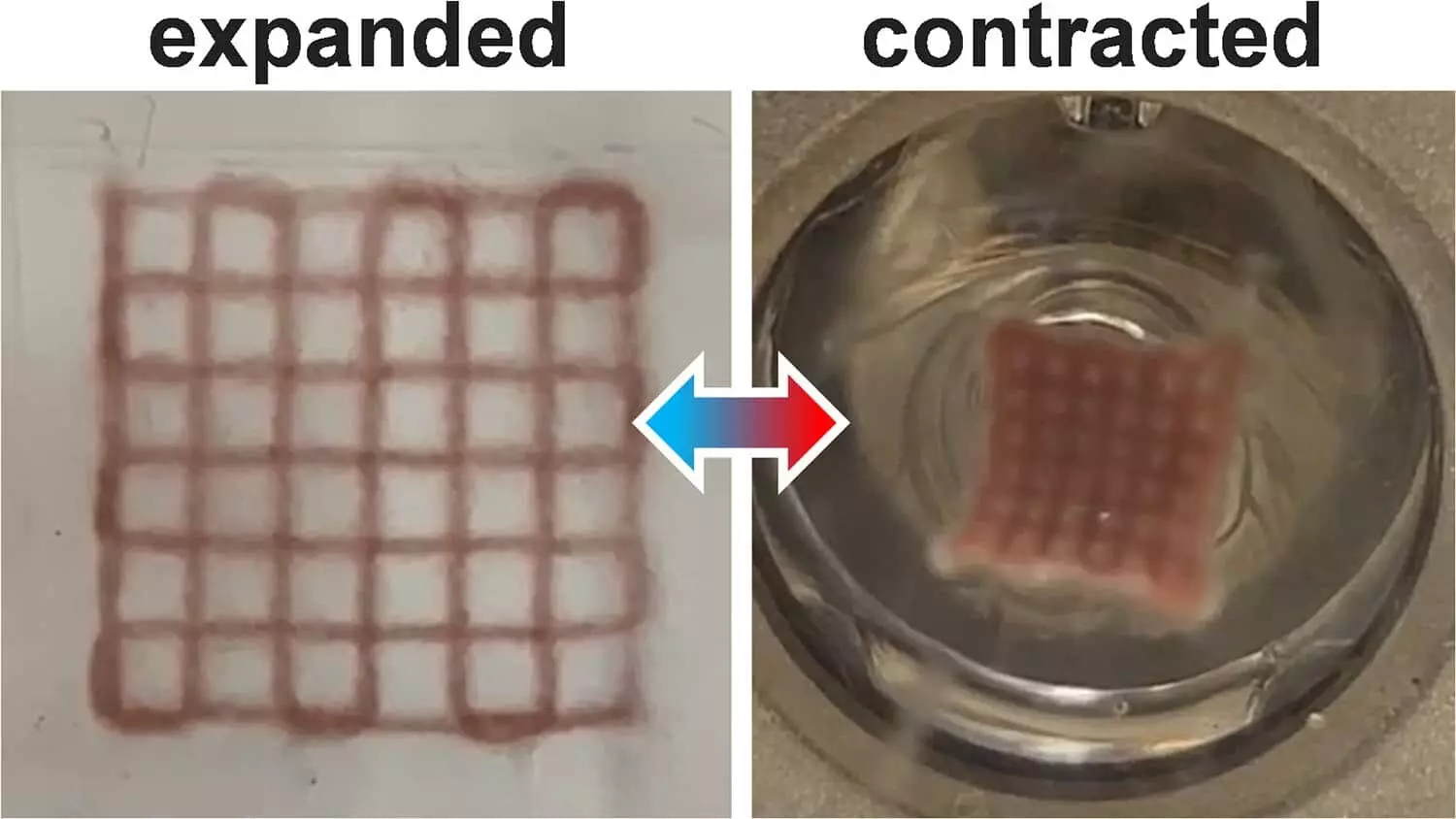

The beauty of this technology lies in its ability to convert light into mechanical motion. Traditionally, actuators have relied on heat or electricity to induce motion, which can often be limiting or cumbersome. The research team, led by professionals such as Joe Tracy from North Carolina State University, have illustrated that by blending gold nanorods within a hydrogel matrix, they can exploit the photothermal effect, wherein light causes localized heating. This process is fundamental as it enables the hydrogel to contract when exposed to light and expand back upon light removal, functioning seamlessly as a remote-controlled actuator.

A Marvellous Blend of Science and Engineering

Hydrogels, which are soft, water-containing polymer networks, are widely recognized for their impressive biocompatibility and adaptable properties. While previous research has explored their capacity to contract upon heating, the quest to achieve similar results using light was still in its infancy. The combination of photothermal properties and 3D printing opens new avenues for customization that traditional molding techniques simply can’t match. By employing a technique where the hydrogels are printed from a solution containing both the hydrogel precursors and gold nanorods, scientists bypass the issue of low viscosity that often hinders effective 3D printing.

A pivotal innovation in this research was the use of a translucent gelatin slurry. This clever workaround serves as a supportive medium that allows the printing of the hydrogel solution without losing the desired structural integrity. When the gelatin is ultimately removed—by gently melting it away in warm water—the result is a meticulously crafted hydrogel structure, intricately designed and effective at executing light-triggered motion.

Applications That Could Change the Game

With the enhancement of hydrogel structures that are responsive to light, the applications of this technology could be wide-ranging and transformative. For instance, the medical field stands to gain significantly. Catheters coated with these smart materials could react to pinpointed light sources, adjusting their shape or rigidity based on the specific conditions within the body. Moreover, soft robotics can benefit from this technology’s agility and adaptability, enabling robots to navigate complex environments with human-like dexterity.

Furthermore, this technology offers unique opportunities in the field of sustainable technology. The ability to trigger movements without mechanical components opens the door to less invasive and more environmentally friendly solutions in various applications. For instance, in the realm of agriculture, hydrogel actuators could be utilized in smart irrigation systems, responding to sunlight to adjust water distribution, thereby optimally directing resources based on the environmental needs.

Looking Ahead: The Promise and Challenges

While the benefits of this technology are tantalizing, the researchers acknowledge various challenges that lie ahead, particularly in terms of scalability and real-world application. Developing materials that not only maintain high performance and efficiency under diverse conditions but also remain cost-effective is essential for broader adoption. Moreover, refining the 3D printing process to ensure seamless integration into existing manufacturing pipelines will be crucial.

This innovative research represents a significant leap towards a new generation of materials that meld the physical with the digital at the speed of light. If these advancements can bridge the gap from laboratory assays to industrial applications, we could very well witness a paradigm shift in how we approach the design of responsive materials. The future of smart actuators may be more dynamic and accessible than ever, heralding new multi-functional capacities that could very well sync with the fundamentals of human ingenuity and creativity.

Leave a Reply