A novel approach to address environmental challenges is developing and commercializing robust hydrogen fuel cells. These fuel cells contain a polymer electrolyte membrane that acts as a barrier between the electrodes. While the membrane conducts protons, it inhibits the movement of electrons, hydrogen molecules, and oxygen molecules. However, the repetitive deformation of the membrane over time can lead to the formation of cracks, compromising the fuel cell’s performance. Although previous methods have been implemented to tackle this issue, such as radical scavengers and hydrocarbon electrolyte membranes, they have not been entirely successful in preventing crack formation and propagation.

In a recent study published in the journal Advanced Materials, researchers from Incheon National University and Harvard University have made a significant breakthrough in fuel cell technology. Led by Associate Professor Sang Moon Kim and Professor Zhigang Suo, the team developed a polymer electrolyte membrane that is resistant to fatigue. Their objective was to create an electrolyte membrane that can withstand the repetitive stress and strain caused by the fluctuations in fuel cell operation.

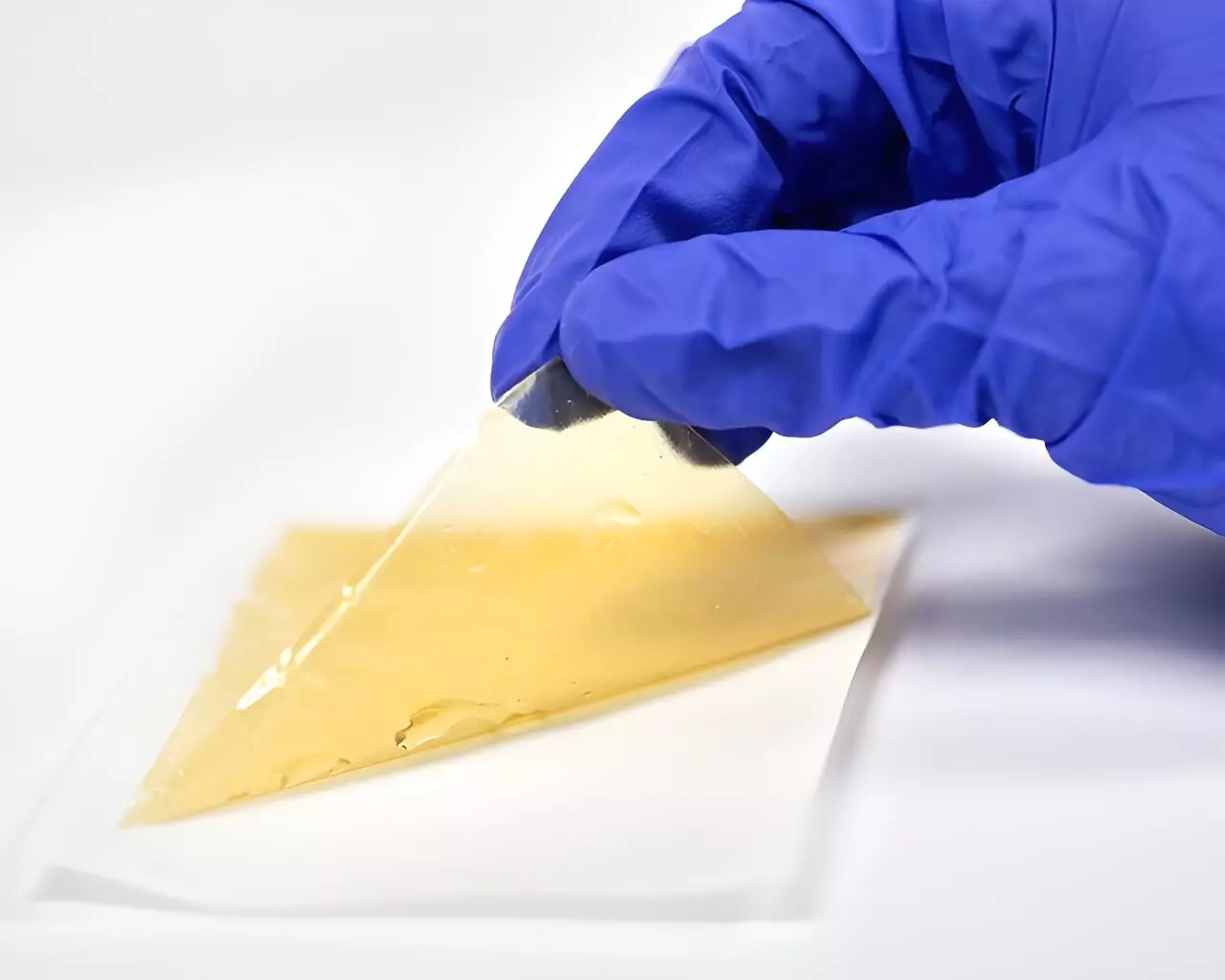

In their study, the researchers created a new category of fatigue-resistant electrolyte membranes using an interpenetrating network of Nafion and perfluoropolyether (PFPE). Nafion is a commonly used plastic electrolyte with proton-conducting properties, while PFPE forms a durable, rubbery polymer network. While the introduction of PFPE slightly reduces electrochemical performance, it significantly enhances fatigue threshold and lifespan. Among the membranes produced, the one with 50% saturation of PFPE demonstrated reasonable electrochemical performance.

Compared to the original Nafion membrane, the Nafion-PFPE composite membrane exhibited a 175% increase in fatigue threshold and a 1.7 times longer lifespan. The unmodified Nafion membrane had a lifespan of 242 hours, whereas the composite membrane lasted 410 hours. These results indicate that while incorporating the rubbery network may slightly reduce electrochemical performance, it substantially improves fatigue resistance and overall lifespan.

This study has significant implications across various industries and applications. The development of a fuel cell system with enhanced stability, durability, and performance can revolutionize fuel cell vehicles and pave the way for advancements in other technologies. In addition to powering vehicles, this breakthrough can impact the development of drones, personal air vehicles, backup power sources, forklifts, bicycles, scooters, and more. Furthermore, the strategy employed to enhance fatigue resistance can also be applied to ion filters, battery separators, and actuation systems. This opens up possibilities for high-durability, long-life desalination filters, flow battery separators, lithium metal battery separators, and artificial muscles.

The development of fatigue-resistant electrolyte membranes represents a significant advancement in fuel cell technology. With the ability to withstand repetitive stress and strain, these membranes have the potential to enhance the stability and durability of fuel cells. While some trade-offs in electrochemical performance may exist, the overall improvement in fatigue resistance and lifespan make these membranes highly promising for a wide range of applications. As researchers continue to refine this technology, we can anticipate further breakthroughs that will accelerate the adoption of fuel cells in various industries and contribute to a greener and more sustainable future.

Leave a Reply