Cellulose is a versatile material that is commonly used in the creation of hydrogels. However, the process of creating hydrogels from cellulose is often complicated and involves the use of toxic solvents. Researchers from North Carolina State University have developed a new, nontoxic method for making cellulose gels inspired by the nest-making process of small birds. This innovative approach has the potential to revolutionize the field of hydrogel production and opens up new possibilities for applications such as drug delivery.

Traditional methods of producing cellulose hydrogels often require the use of difficult-to-handle, unstable, or toxic solvents. This poses both environmental and health risks. In addition, the process of dissolving the cellulose and inducing it to crosslink or form the desired structure is tricky and time-consuming. Finding a more efficient and environmentally friendly method is crucial for advancing the field of hydrogel production.

Researchers took inspiration from the nest-making process of small birds, particularly the swift family, to develop a new approach for creating cellulose gels. These birds use their saliva as a natural resin to hold twigs in place and encourage the fibers within the nest to interconnect. By mimicking this process, the researchers aimed to achieve the same interconnection of fibers within the cellulose gel.

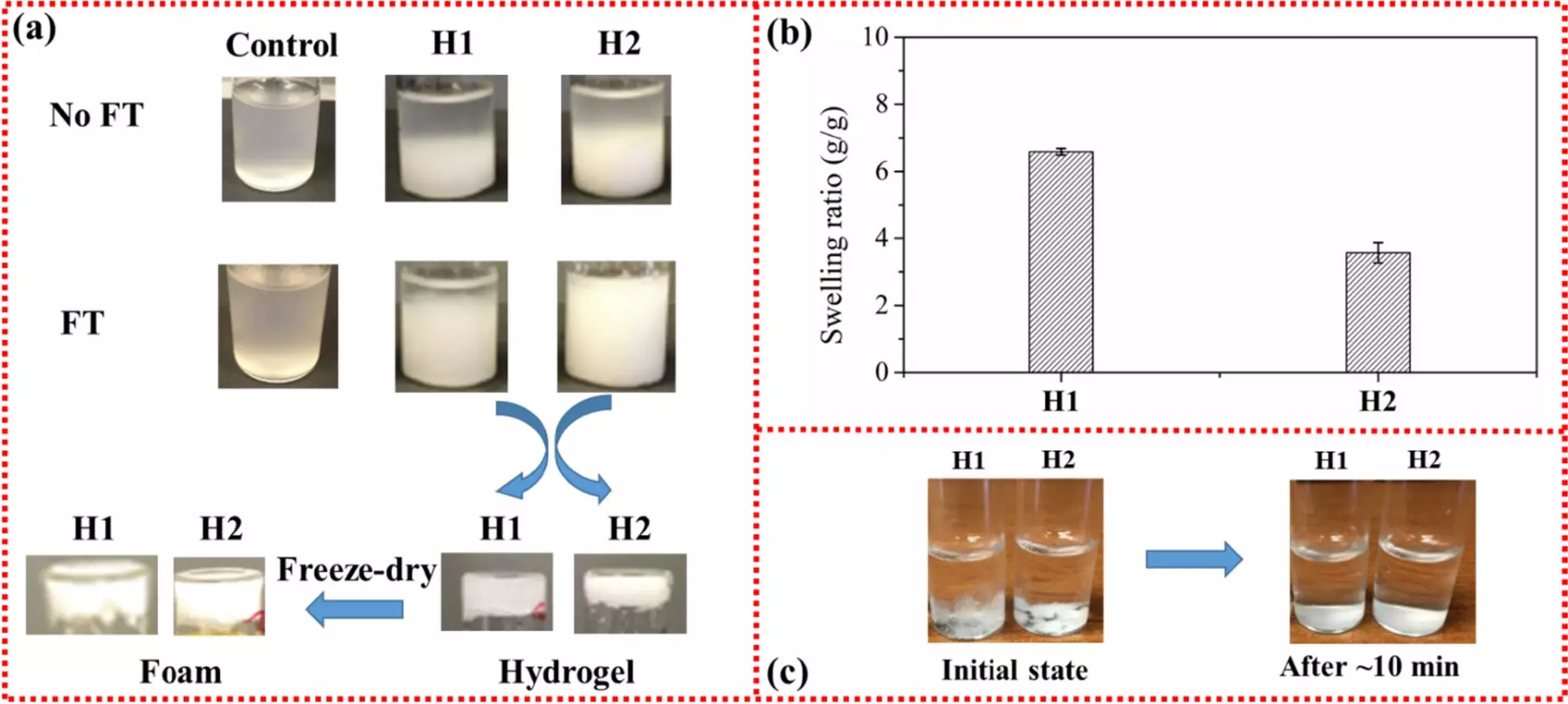

To replicate the bird’s nest-building process, the researchers used a water-soluble cellulose called carboxymethyl cellulose (CMC) and dissolved it in an acid solution. They then introduced powdered cellulose fiber to the solution and subjected it to four rounds of freezing and thawing. This freeze-thaw process caused the cellulose to compact and interweave into a more organized structure, similar to the interconnection of fibers in the bird nests.

The outcome of the experiment was the successful formation of cellulose gel. This gel demonstrated robustness and stability at room temperature. Further experimentation with freeze drying resulted in the creation of cellulose foam. The researchers also tested the process with bamboo fibers, suggesting its potential applicability to other lignin- and cellulose-containing fibers.

The newly developed cellulose gels have several promising applications, including drug delivery. The gels can be tuned to degrade at a specific rate, allowing for timed drug release. This feature opens up opportunities for controlled release of medications, ensuring optimal therapeutic effects. Additionally, the nontoxic nature of the process makes it an environmentally friendly alternative to traditional methods.

The development of a novel approach to create cellulose gels based on the nest-making process of small birds presents an exciting advancement in the field of hydrogel production. By mimicking the interconnection of fibers achieved through bird saliva, the researchers have successfully created cellulose gels using a simple and cost-effective freeze-thaw process. These gels demonstrate robustness, stability, and the ability to be tuned for timed drug delivery. The potential applications of this research extend beyond drug delivery and offer solutions for various fields that utilize hydrogels. This innovation paves the way for a more sustainable and efficient future in cellulose gel production.

Leave a Reply