Advancements in lithium-ion battery technology are crucial for the growth and widespread adoption of electric vehicles (EVs). Researchers at the Department of Energy’s Pacific Northwest National Laboratory have made a groundbreaking discovery that could revolutionize EV battery performance. By developing a cost-effective method for synthesizing single-crystal, high-energy, nickel-rich cathodes, they have overcome a major bottleneck in lithium-ion battery manufacturing.

The cathode of a lithium-ion battery plays a critical role in determining its energy capacity and overall performance. Conventional EV batteries use cathodes composed of a mixture of metal oxides, known as lithium nickel manganese cobalt oxides (LiNi1/3Mn1/3Co1/3O2), or NMC. The incorporation of nickel into the cathode increases the battery’s energy storage capabilities, making it essential for improving the range of EVs.

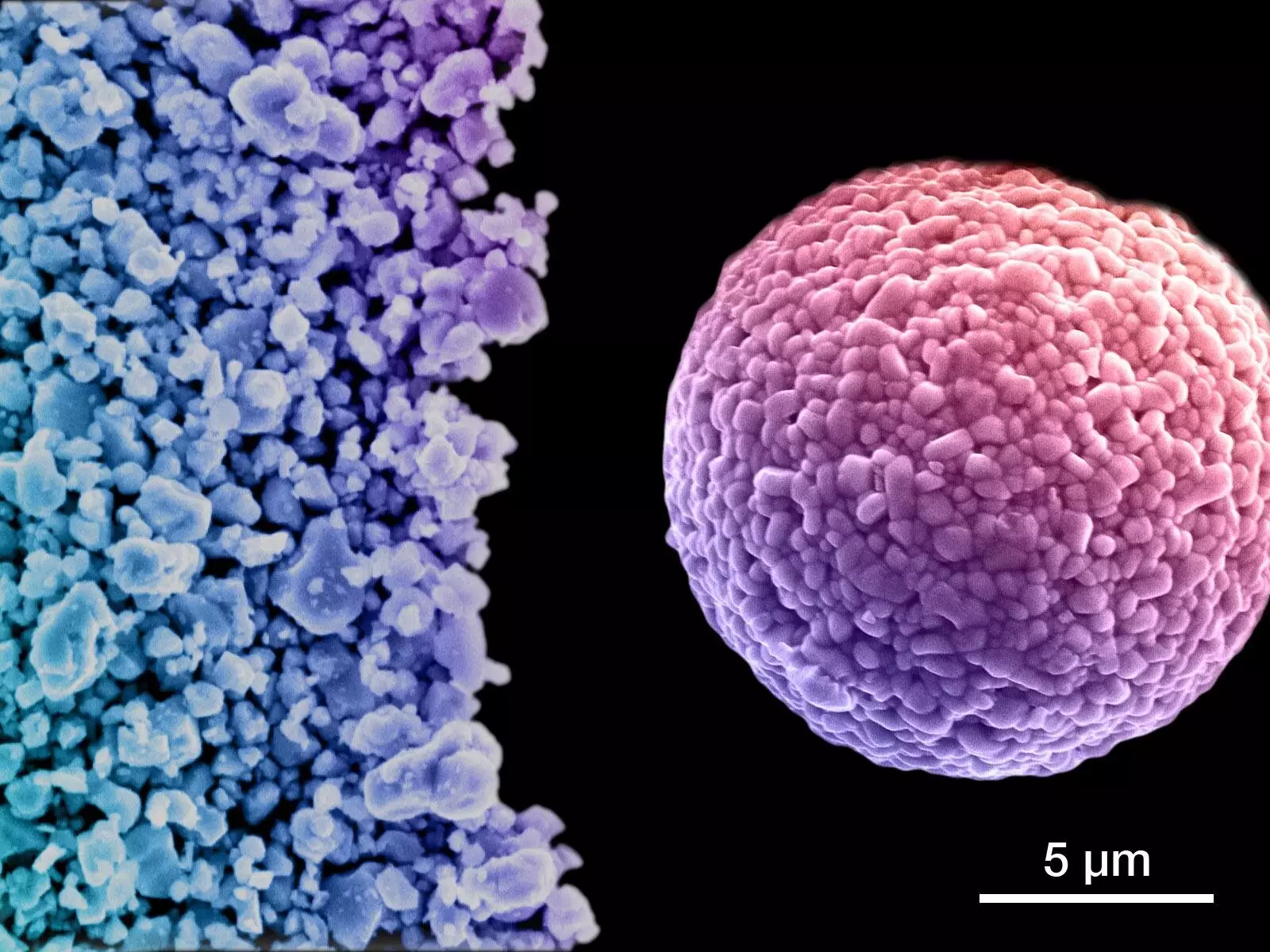

However, high-nickel NMC cathodes have significant drawbacks. The standard manufacturing process results in polycrystal structures with a lumpy and rough texture. These structures are prone to splitting apart, leading to material failure and reduced battery lifespan. High-nickel NMC cathodes also tend to crack, produce gases, and decay faster compared to cathodes with lower nickel content.

To address the limitations of current cathodes, the research team led by PNNL battery experts collaborated with Albemarle Corporation to develop a groundbreaking solution. They introduced a pre-heating step during the manufacturing process, which changed the structure and chemical properties of the transition metal hydroxide precursor. When this pre-heated precursor reacts with lithium salt to form the cathode, it results in a uniform single-crystal NMC structure.

This innovative synthesis method produces single-crystal cathodes with a smooth surface. The single-crystal NMC811, containing 80% nickel, was successfully scaled up to kilogram levels using lithium salt provided by Albemarle. The researchers tested the scaled single crystals in realistic 2Ah lithium-ion pouch cells, ensuring that the battery’s performance was primarily dictated by the new cathode.

The first prototype battery equipped with the single-crystal NMC811 cathode demonstrated exceptional stability, even after 1,000 charge and discharge cycles. Microscopic analysis of the crystal structure revealed no defects and a perfectly aligned electronic structure. This breakthrough has significant implications for the future of lithium-ion batteries, especially in terms of energy density and lifespan.

Stan Whittingham, a Nobel Laureate and distinguished professor of chemistry, emphasized the importance of this breakthrough for enabling the use of high-energy density batteries without degradation. He also highlighted the role of long-lived batteries in supporting clean renewable energy sources and making the grid more resilient.

The synthesis method for single-crystal cathodes is not only innovative but also cost-efficient. The drop-in approach allows cathode manufacturers to utilize existing production facilities to conveniently produce single-crystal NMC811 cathodes, and potentially cathodes with more than 80% nickel. Jie Xiao, the principal investigator of the project, stated that this manufacturing process opens a new direction for large-scale production of single-crystal cathode materials.

The research team plans to commence the commercialization phase in early 2024. They will collaborate with industry and university partners to realize commercial-scale synthesis and testing. Conventional manufacturing equipment and techniques will be leveraged, incorporating PNNL’s scale-up approach and further innovations to reduce costs and waste generation.

This breakthrough discovery in lithium-ion battery manufacturing represents a significant step toward enhancing the performance and longevity of electric vehicle batteries. By addressing the limitations of current cathodes, the research team at PNNL has paved the way for more energy-dense and durable batteries. As EVs continue to gain popularity and become a mainstream transportation option, improved battery technology is vital for accelerating the transition to a sustainable, electrified future.

Leave a Reply