Safeguarding industrial and domestic environments from toxic gases is crucial, yet existing detection systems often fall short due to their limited lifespan. However, a recent breakthrough at MIT offers a promising solution. Researchers have successfully developed a novel detector that enables continuous monitoring of toxic gases at a low cost, revolutionizing the field of gas detection technology.

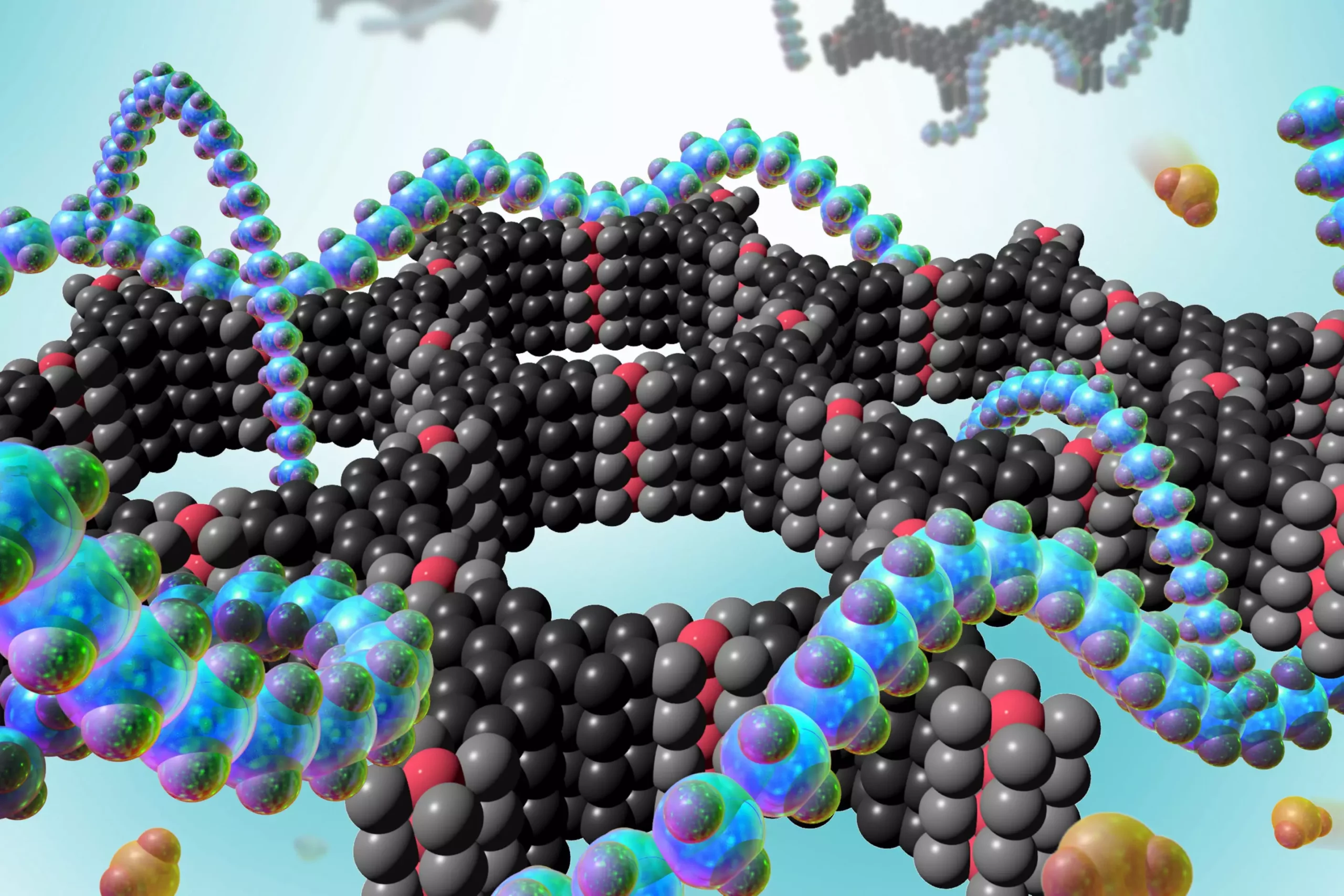

The team at MIT ingeniously combined two distinct technologies to create this groundbreaking detector. By leveraging the exceptional sensitivity of metal-organic frameworks (MOFs) to trace amounts of gas and pairing it with the durability and processing ease of polymers, they were able to overcome the limitations of each material. This fusion of MOFs with conductive polymers heralds a new era in gas detection capabilities.

Metal-organic frameworks, known for their high porosity and large surface area, possess remarkable gas-capturing abilities due to their sponge-like structure. However, their susceptibility to saturation renders them unsuitable for prolonged use. To address this issue, the team introduced a conductive polymer composite that facilitates the reversible detection of gases without permanent binding, thereby ensuring the sensor’s longevity and reusability.

Operational Mechanism

The composite material undergoes a shift in its electrical resistance when gas molecules temporarily adhere to its surface. This alteration in resistance can be continuously monitored using an ohmmeter, allowing for real-time tracking of gas presence. Through meticulous experimentation, the researchers demonstrated the sensor’s efficacy in detecting nitrogen dioxide, a prevalent toxic gas associated with combustion processes, at concentrations as low as 2 parts per million.

Long-Term Viability

After subjecting the material to 100 detection cycles, the sensor maintained its baseline performance within a narrow margin, showcasing its robustness and potential for long-term application. Moreover, the composite exhibited superior sensitivity compared to conventional nitrogen dioxide detectors, underscoring its effectiveness in detecting low concentrations of the gas, which is crucial for mitigating health hazards.

Beyond nitrogen dioxide detection, the composite’s versatility allows for customization to target various volatile molecules, making it a versatile tool in gas monitoring strategies. The thin, uniform film deposition enabled by the polymer ensures cost-effective production methods, paving the way for widespread implementation in industrial and residential settings. By scaling up the synthesis of these polymers, the sensor’s mass production and integration into real-world environments could soon become a reality.

The development of this cutting-edge gas detector by MIT researchers represents a significant leap forward in continuous toxic gas monitoring. By harnessing the unique properties of metal-organic frameworks and conductive polymers, they have created a sensor that offers unparalleled sensitivity, longevity, and cost-efficiency. With further research and field testing, this innovative technology has the potential to enhance safety measures and protect human health in a variety of environments.

Leave a Reply