In the rapidly evolving field of energy storage, NCM811 (nickel cobalt manganese) materials have emerged as prominent candidates for next-generation lithium-ion batteries. Due to their high energy density, these materials hold the potential to revolutionize electric vehicles and renewable energy storage. Yet, despite their promise, NCM811 life cycles are often curtailed by the development of micro-cracks in poly-crystalline structures, largely due to the stresses imposed during charge and discharge cycles. This degradation is a significant hurdle that impacts their long-term performance and reliability.

Given the critical nature of these stress-related issues, understanding the chemo-mechanical dynamics of NCM811 materials is essential for improving battery longevity. The interplay between chemical processes, such as lithiation and delithiation, and mechanical stresses can result in significant structural damage. Addressing these issues requires sophisticated monitoring techniques that can detect changes at the material level. Advances in this field are vital not only for extending battery life but also for optimizing their overall performance.

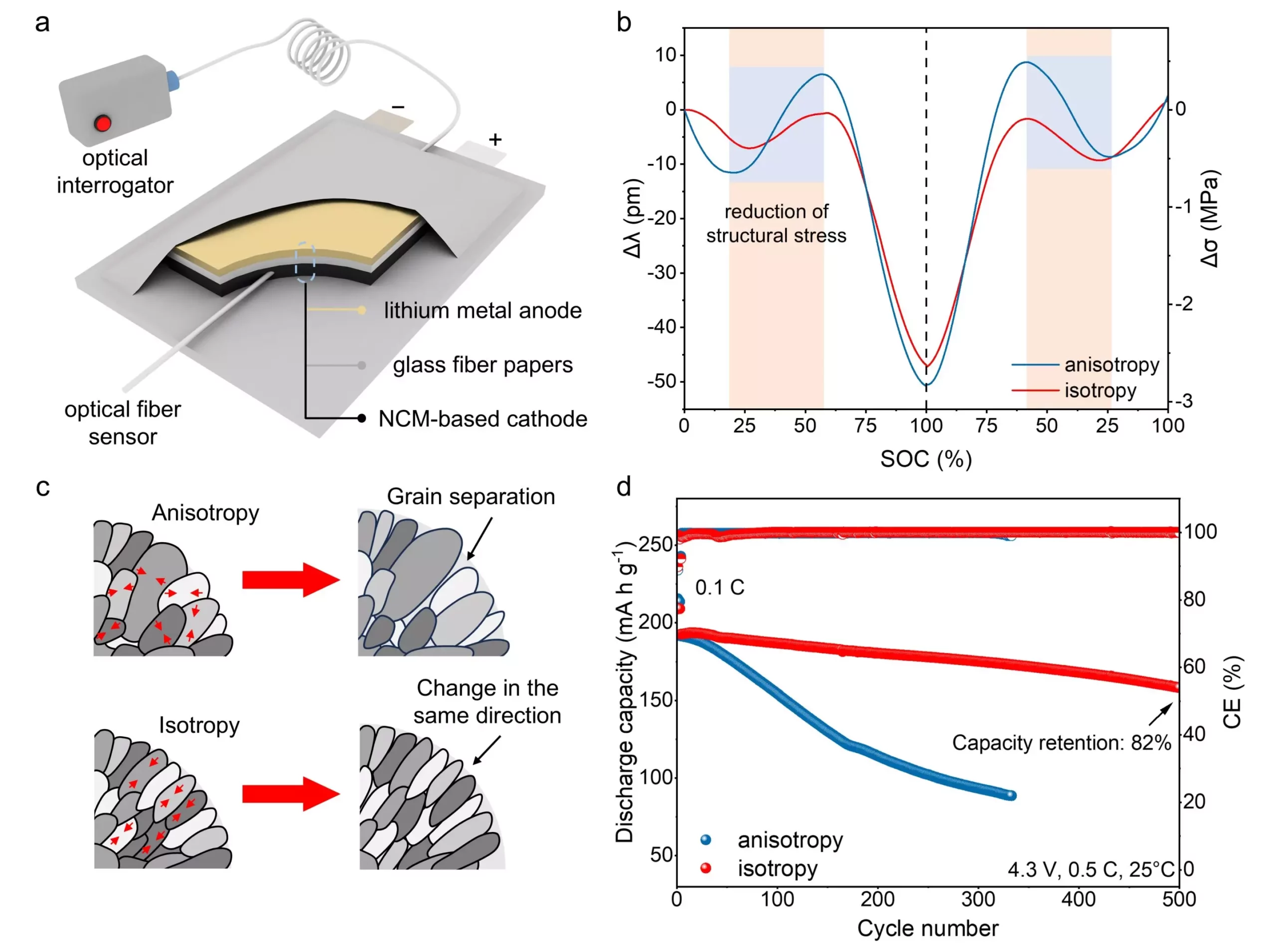

To tackle these challenges, a research group led by Professors Yunhui Huang and Zhen Li has introduced an innovative approach that employs optical fiber technology. By embedding optical fibers within the NCM811 cathode, they can achieve real-time monitoring of stress evolution during battery operation. This approach offers a promising avenue for tracking the mechanical integrity of the materials as they undergo dynamic changes in response to electrochemical processes. Importantly, the minimal size and high chemical stability of the optical fiber ensure that it does not interfere with the battery’s functionality or the transmission of sensing signals, thus providing essential data without compromising performance.

The study reveals that stress development in poly-crystalline NCM811 primarily comprises two types of stress: chemical and structural. Chemical stress—an inherent feature of the lithiation process—operates within expected parameters. In contrast, the more detrimental structural stress is a precursor to crack formation, leading to significant performance degradation. This structural stress arises chiefly from the shifting c-axis of the crystal lattice during charge cycles and the anisotropic nature of primary particles. Understanding these stressors is crucial for enhancing the material’s stability and performance.

Recognizing the critical need to mitigate structural damage, researchers propose refining the anisotropic characteristics of the primary particles. By promoting a more ordered arrangement within the material, it may be possible to create a battery structure that better withstands the stresses of operation. Preliminary results indicate that such an ordered arrangement significantly alleviates structural stress, yielding improvements in performance metrics. For instance, the modified NCM811 materials demonstrated a remarkable capacity retention of 82% after 500 cycles, underscoring the importance of these engineering advancements.

As the field of battery technology continues to advance, the integration of optical sensing techniques showcased by Prof. Huang and Prof. Li represents a major leap forward in the quest for safer, more durable batteries. The researchers assert that ongoing innovations in optical sensing will play a pivotal role in not only understanding but also improving the structural integrity of battery materials. This synergy between sensing technology and material science could ultimately lead to the development of batteries that are not only high-performing but also reliable and safe for widespread adoption in various applications. As this research progresses, it stands to redefine the landscape of battery engineering and performance metrics.

Leave a Reply