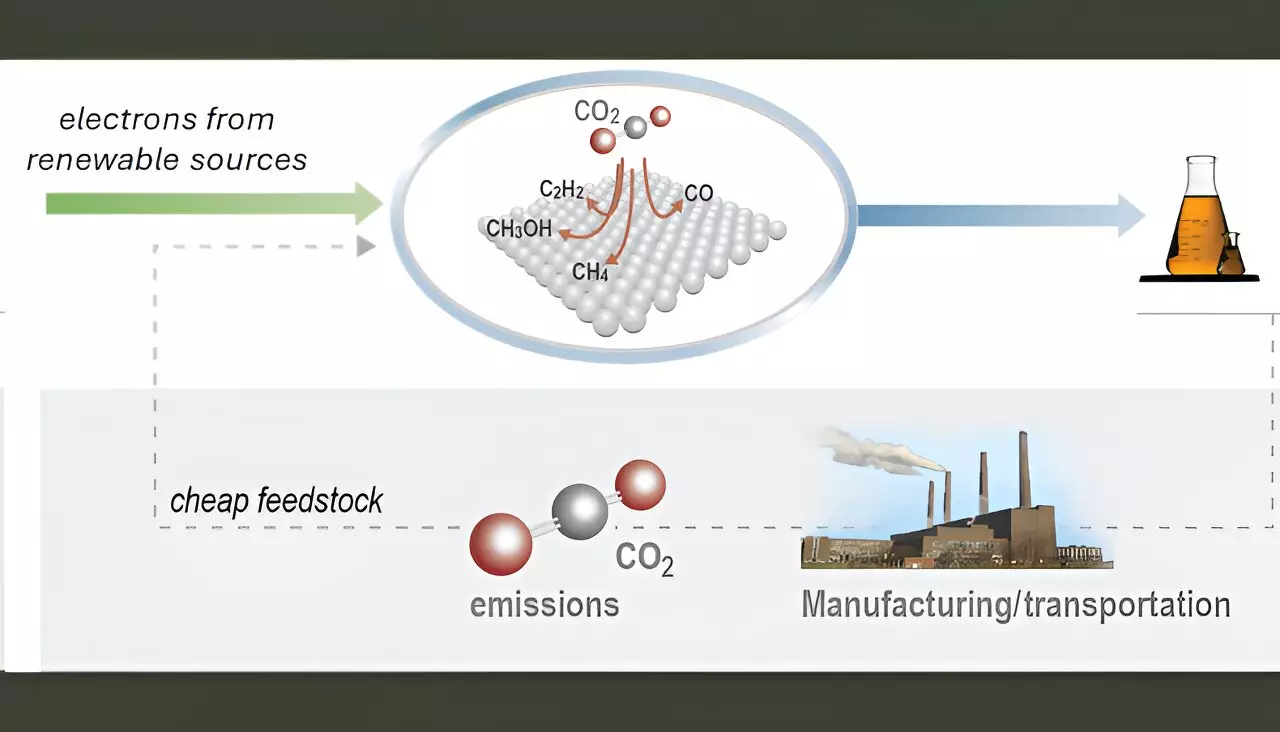

The pressing challenge of climate change has stimulated numerous groundbreaking approaches aimed at carbon management, especially focusing on the conversion of carbon dioxide (CO2) into valuable materials. Among the most promising methods is the coupling of CO2 electrochemical conversion with renewable energy sources like solar and wind power. This strategy not only holds the potential for sustainable production of high-demand chemicals and fuels but also aligns industries with a more environmentally friendly trajectory. Products from this conversion, such as ethylene, ethanol, and acetic acid, serve as vital feedstocks for various applications, including the chemical and transportation sectors.

Electrolyzers, devices that facilitate chemical reactions using electrical energy, are at the forefront of CO2 conversion technologies. They have undergone significant design enhancements to achieve high current densities typical of industrial standards. However, the journey toward commercializing these technologies faces significant hurdles, primarily linked to the stability and selectivity of the catalysts used in these processes. Catalysts are crucial because they determine not only the efficiency of the reaction but also the types and quantities of products that can be generated from CO2.

To address the challenges facing catalyst performance, researchers at Lawrence Livermore National Laboratory (LLNL) have pioneered a novel catalyst coating platform using physical vapor deposition (PVD). This approach offers an exceptional level of control over several vital parameters, including coating thickness, composition, morphology, and porosity. Such control is essential because it allows for the systematic tuning of catalyst properties without altering their integration into electrolyzers. This decoupling is of tremendous importance as it eliminates confounding variables that often complicate comparisons between different catalysts.

The LLNL team, in collaboration with researchers from other prestigious institutions like the University of Delaware and Washington University, has focused on copper and its alloys as promising candidates for effective CO2 conversion. Historically, reliable conversion of CO2 into multi-carbon products has been limited mainly to copper-based catalysts. By using their PVD platform, the researchers explored innovative copper-based dilute alloy catalysts, providing insights into the potential of these materials to enhance CO2 in multicarbon product synthesis.

The team’s work not only confirmed the utility of copper alloys but also revealed how these can be tailored to improve the electrochemical processes involved. Specifically, the research demonstrated that these dilute alloys can bolster the coupling of carbon monoxide, an intermediate in the CO2 reduction process, into more complex products. According to LLNL scientist Joel Varley, the simulation work has shown that orchestrating the energy landscape through dilute alloy chemistry is an effective strategy for developing cleaner chemical feedstocks.

When comparing PVD to traditional electrodeposition methods, the benefits extend beyond just performance. PVD is noted for producing fewer waste materials and requiring less labor, which substantially reduces operational expenditures despite the higher initial capital expenses associated with the equipment. This efficiency can make PVD a more economically viable choice for manufacturers in the chemical and transportation sectors looking to transition toward more sustainable practices.

The innovations stemming from LLNL’s research signify a potential turning point for industries aiming to reduce their carbon footprint. By developing effective catalysts that can convert CO2 emissions into valuable products, a closed-loop system emerges where waste gases can be reused, ultimately promoting a circular economy. As further advancements are made in catalyst technology and deployment techniques, the transition to a more sustainable chemical and fuel production landscape may finally be within reach.

The integration of renewable energy with novel catalyst technologies holds considerable promise for the future of carbon management and climate change mitigation. Continued research and development in this area will likely yield significant breakthroughs that can facilitate a cleaner and more sustainable global economy. As researchers tackle the existing challenges, like catalyst stability and scalability, the collaborative efforts across institutions could pave the way for transformative change in how we utilize CO2 resources, turning a greenhouse gas into a valuable asset.

Leave a Reply