Engineers at the University of California San Diego are pioneering a transformative approach to 3D printing that merges simplicity with sustainability. Their innovative technique employs a liquid polymer ink and a salt water solution to fabricate solid structures, culminating in findings published in the prestigious journal Nature Communications. This novel method not only streamlines the manufacturing process but also holds substantial promise for reducing the environmental impact traditionally associated with materials fabrication.

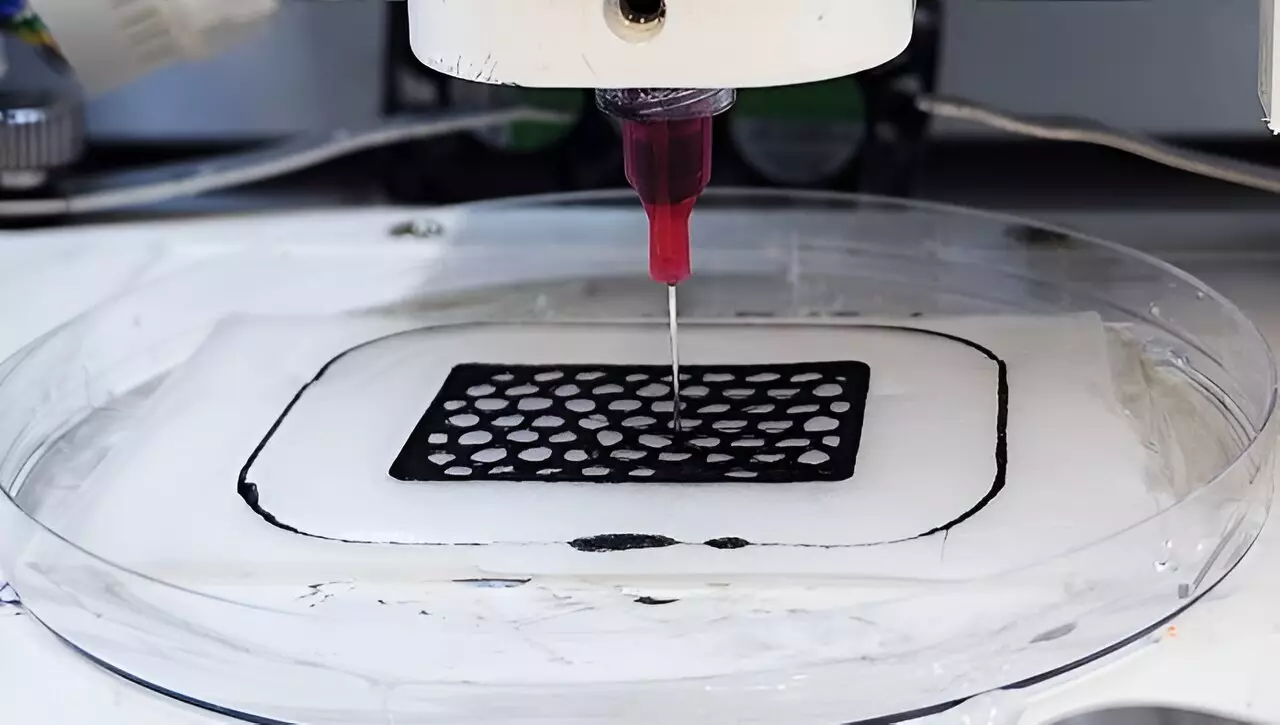

At the core of this new technique is a unique polymer known as poly(N-isopropylacrylamide) or PNIPAM. When the PNIPAM ink, which remains liquid under standard conditions, is extruded through a needle into a calcium chloride salt solution, it reacts instantaneously. This immediate solidification is attributed to the salting-out effect, a natural phenomenon whereby salt ions actively engage with water molecules, effectively eliminating them from the polymer solution. The loss of water compels the hydrophobic polymer chains within the PNIPAM to condense, thus transforming the liquid into a solid form almost effortlessly.

Senior researcher Jinhye Bae emphasizes the remarkable simplicity of this process, noting that it functions effectively under ambient conditions—eliminating the need for complex machinery or energy-consuming procedures common in traditional polymer solidification methods. Unlike conventional techniques that often rely on toxic chemicals or excessive heat, the team’s approach champions minimalism and efficiency.

One of the most significant implications of this new technique is its reversibility. The solid constructs created through this method can be dissolved in fresh water, reverting back to a liquid state. This feature not only permits the reuse of the PNIPAM ink but also presents a compelling argument for recycling polymer materials in a way that is both practical and environmentally responsible. Bae highlights this as a pivotal step toward more sustainable manufacturing practices in the polymer industry.

The versatility of this method was illustrated through the printing of a functional electrical circuit made from a composite of PNIPAM and carbon nanotubes. Notably, this circuit successfully powered a light bulb and could also be entirely dissolved in water, showcasing the potential for water-soluble electronic components. This aspect of the technique could revolutionize how we think about the lifecycle of electronic materials and their disposability.

Looking ahead, Bae and her team envision that their straightforward and reversible 3D printing method could lead to a broader range of environmentally friendly practices within polymer manufacturing. By integrating such sustainable technologies, industries can reduce their reliance on energy-intensive, hazardous processes, thereby ushering in a new era of eco-conscious engineering.

The research conducted at UC San Diego heralds a significant advancement in the field of 3D printing, proving that traditional barriers can be overcome through innovation and a commitment to sustainability. The ability to fabricate, dissolve, and recycle structures using eco-friendly materials could redefine manufacturing standards, encouraging a shift toward practices that prioritize environmental responsibility without sacrificing functionality. The future of 3D printing looks promising, with the potential to create a positive impact on both industry and the planet.

Leave a Reply