Fluidic technologies are integral to the modern world, prompting advancements across various industries. The quest to design systems capable of accurately capturing and releasing liquids has been an ongoing challenge. Traditional methods often fall short due to their inability to provide precise control over the timing, volume, and spatial manipulation of fluids. However, a groundbreaking development from researchers at The Polytechnic University of Hong Kong (PolyU) promises to transform this domain significantly.

Unveiling the ‘Connected Polyhedral Frames’

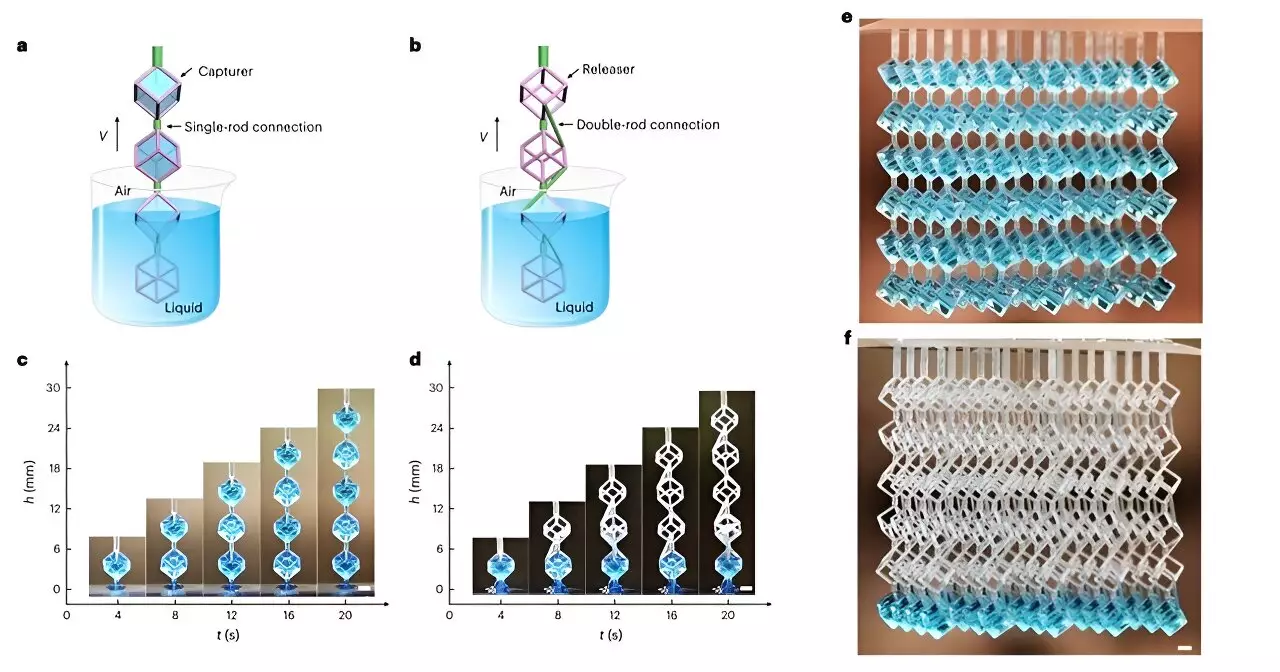

The research team, led by Professor Wang Liqiu and featuring Dr. Zhang Yiyuan as the principal author, introduced an innovative system called “Connected Polyhedral Frames” (CPFs). The significant strength of the CPFs lies in their ability to toggle between the capture and release of different types of liquids in a way that is both reversible and programmable. This versatility sets CPFs apart as a meta-metamaterial, opening avenues for unprecedented applications in fields that rely heavily on fluid management such as healthcare, pharmaceuticals, and chemical engineering.

CPFs operate on a novel framework that enables them to capture liquids in one configuration and release them in another. The ingenious design features frames that can be adjusted to create liquid flow pathways when required, thus overcoming the limitations faced in fluid manipulation—challenges such as liquid cross-contamination and difficulties in accurate volume transfer. This innovation offers a potential solution to the pervasive issues posed by disposable plastic tools like pipettes, which contribute substantially to global plastic pollution.

One of the most pressing issues within fluid handling technologies is fluid adherence, which often leads to incomplete transfers and contamination. In many traditional systems, tools become saturated with the liquids they handle, further complicating the process. The researchers at PolyU recognized that current methods of fluid management did not leverage the full potential of technological advances in material science and fluid mechanics. With CPFs, the researchers took a bold step towards a holistic solution to fluid control that could usher in a new era of efficiency and precision.

By employing a dual-rod and single-rod connection set-up, CPFs can switch fluid states efficiently. When positioned correctly, they can either retain or release captured liquids, altering their function based on the need without permanent changes to the structure. This kind of flexibility and efficiency is unprecedented in traditional methodologies.

The applications of CPFs are vast and varied. For instance, the team showcased their system’s capability in drug delivery by implementing a controlled release mechanism for vitamins B2 and B12, encapsulated within sodium alginate and gellan gum. By manipulating the thickness of the gel membranes, the researchers achieved a fine control over the release rates, demonstrating CPFs’ potential not just for pharmaceuticals, but also for precise biochemical applications.

Further, when comparing CPFs to traditional sampling tools like cotton and flocking swabs, CPFs displayed significantly improved performance. During tests involving the influenza virus, CPFs reliably detected the presence of the virus even at lower concentrations, thereby showcasing their sensitivity and effectiveness as diagnostic tools.

Moreover, the implications for microbial applications are equally promising. Using Acetobacterium as a model, the CPFs were found to enhance the separation of bacteria from reaction products, streamlining the microbial reactions and driving productivity higher. Such advancements could lead to greater efficiencies in the production of bioproducts, which are crucial in today’s biotechnological landscape.

Beyond medical and biological fields, the researchers at PolyU have also explored CPFs’ application in sustainable technologies, specifically in air conditioning. By designing a prototype humidifier, the team demonstrated how CPFs could reduce water flow while increasing storage capacity, thereby improving energy efficiency. This application aligns with contemporary goals of minimizing environmental impact while optimizing energy use.

The diverse functionalities of CPFs could also play a significant role in carbon capture initiatives. The design enables the formation of large surface areas for gas absorption, eventuating in systems that could enhance CO2 capture and storage processes—an urgent global need in combating climate change.

The introduction of CPFs represents a pivotal step towards redefining fluid manipulation technologies. Their versatility, combined with high-performance capabilities, could lead to a revolutionary shift in how liquids are handled across various sectors. With this innovation, researchers have set a new standard, paving the way for advancements that harness the power of liquid management in ways previously deemed impossible. The future of fluidic technologies holds boundless possibilities, potentially transforming everything from healthcare to environmental sustainability.

Leave a Reply