Seawater electrolysis has emerged as a key area of interest in the quest for sustainable energy solutions, particularly for hydrogen production. As the world grapples with escalating energy demands and climate change, harnessing the energy potential of seawater for hydrogen fuel presents a viable decarbonization strategy. However, this approach faces significant obstacles, notably anode corrosion due to chloride ions and the high costs associated with efficient catalysts. Overcoming these hurdles is critical to achieving efficient and economic seawater electrolysis on a global scale.

Recent research has spotlighted self-supported nickel-iron (NiFe) materials, which serve as excellent bifunctional catalysts for both the hydrogen evolution reaction (HER) and the oxygen evolution reaction (OER). These materials offer not only high intrinsic activity but are also cost-effective when compared to traditional catalysts. The challenge remains in enhancing the stability and longevity of these catalysts in harsh seawater environments, where corrosive agents can degrade performance over time.

The Role of Wood-Based Carbon Structures

In a bid to improve the overall stability of NiFe catalysts, researchers have turned their attention to utilizing wood-based carbon (WC) structures. These substrates, known for their hierarchical porous designs and superior electrical conductivity, present an ideal foundation for enhancing the performance of electrochemical devices. By leveraging the natural architecture of wood waste, scientists are tapping into a powerful resource that simultaneously addresses waste management and energy production.

Groundbreaking Research and Development

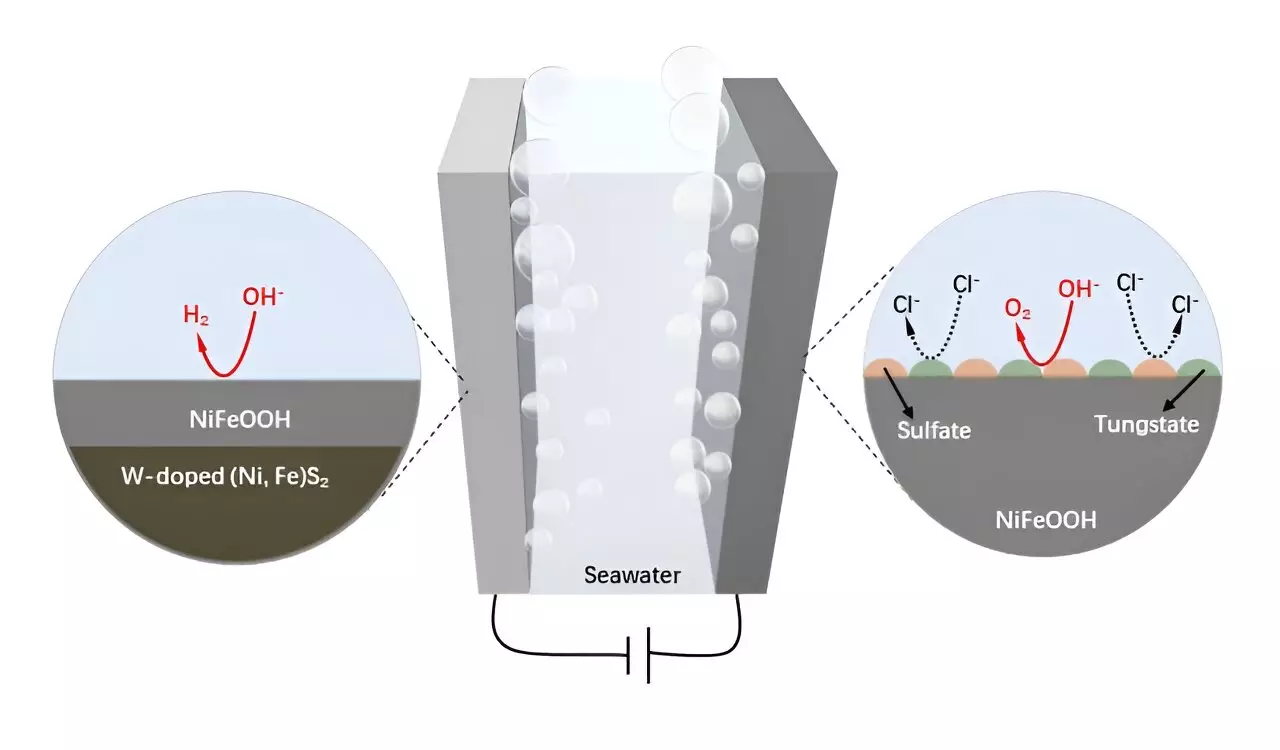

A collaborative study led by Prof. Hong Chen, along with his counterparts from the University of New South Wales and Curtin University, has pioneered an innovative approach involving the introduction of tungsten into NiFe-based catalysts. This research, published in the Science Bulletin, results in the development of a W-doped NiFe sulfide (W-NiFeS) electrode supported by wood-based carbon. The unique preparation method, which includes impregnation and sulfidation, allows the electrode to achieve a three-dimensional hierarchical structure with exceptional porosity. This design is crucial for optimizing electrical conductivity, thereby enhancing the overall efficiency of seawater electrolysis.

The findings indicate that the W-NiFeS/WC electrode offers remarkable performance in both HER and OER, showcasing significant improvements over conventional catalysts. The mechanism behind this enhanced functionality lies in the in situ evolution of structures during the OER process, which results in anti-corrosive byproducts that protect the active sites. As a result, the electrode exhibits not only high activity but also long-term stability in alkaline seawater conditions.

The implications of this groundbreaking research extend beyond just improving electrolysis efficiency; they highlight the potential of repurposing wood waste through a circular economy model. By transforming what would otherwise be waste into functional catalysts, this work embodies a sustainable approach towards hydrogen production from seawater. This innovative method of using bio-derived materials in advanced electrochemical devices encapsulates the dual goals of enhancing energy production while minimizing environmental impact—a crucial step towards achieving a greener and more sustainable energy future.

Leave a Reply