Rare-earth elements (REEs) play a pivotal role in modern technology, particularly in the realm of green energy. Key players like neodymium (Nd) and dysprosium (Dy) are integral to high-performance magnets found in electric vehicles (EVs) and wind turbines. As the demand for such technologies escalates amid a global shift towards sustainability, the efficient recycling of these critical materials has emerged as a pressing challenge. A recent study undertaken by a team of researchers at Kyoto University introduces an innovative solution aimed at transforming the way we approach REE recycling, signaling a potential turning point in this crucial sector.

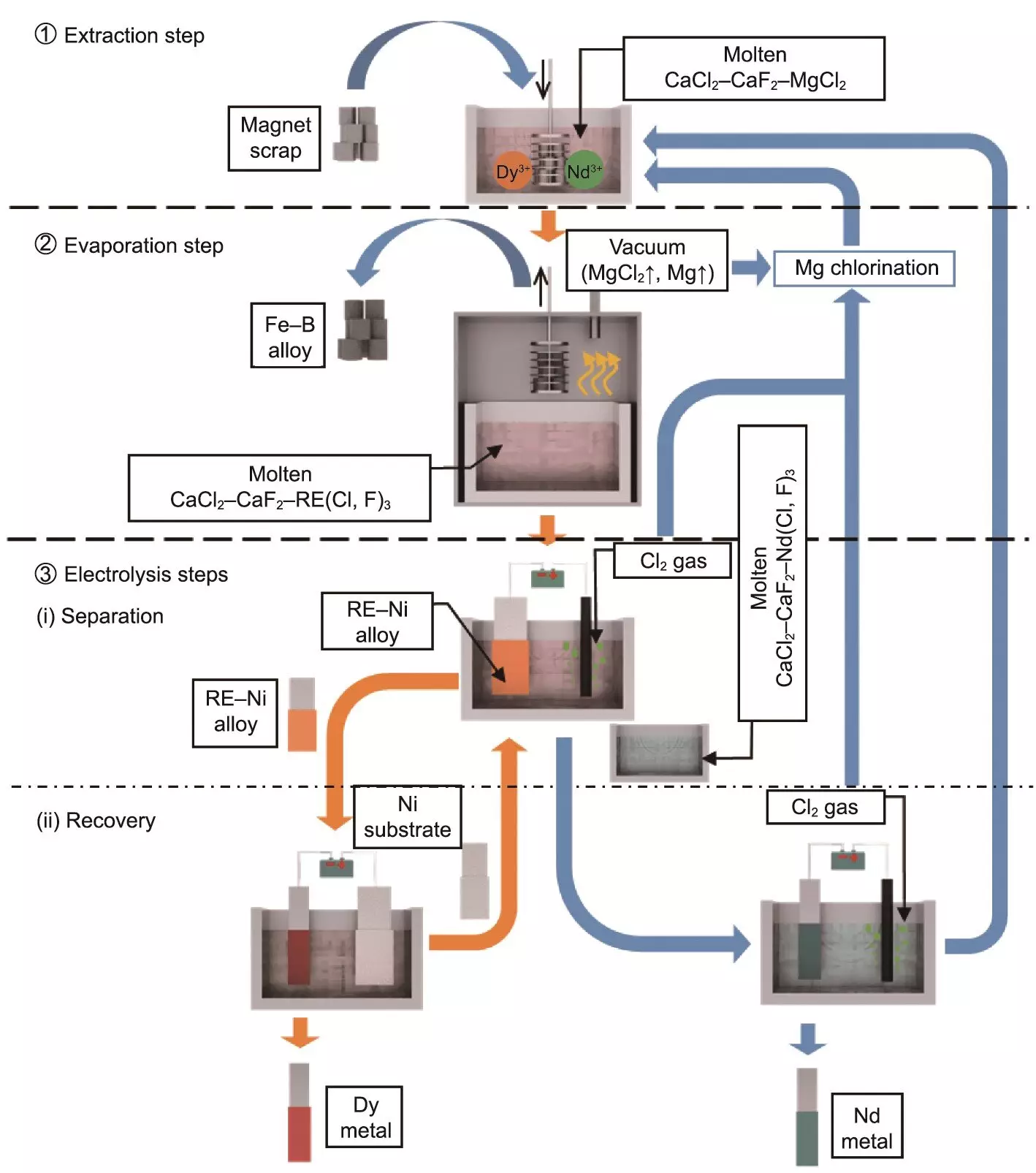

The innovative method developed by the Kyoto University team is referred to as the selective extraction–evaporation–electrolysis (SEEE) process. Unlike conventional hydrometallurgical techniques which are often energy-intensive and environmentally taxing, the SEEE process stands out due to its sustainability and efficiency. At the heart of this method are three distinct yet interconnected stages: selective extraction, selective evaporation, and selective electrolysis.

In the first stage, selective extraction, the process employs a molten salt mixture consisting of calcium chloride (CaCl2) and magnesium chloride (MgCl2) to extract REEs from discarded magnet scraps. The introduction of calcium fluoride (CaF2) in this step is particularly significant, as it helps mitigate evaporation losses while enhancing overall extraction efficiency.

The second stage, selective evaporation, concentrates the extracted REEs by removing any residual agents and byproducts. This purification step is critical in ensuring the subsequent separation process yields high-purity metals. Finally, in the selective electrolysis stage, the REEs are separated through electrochemical means based on their unique formation potentials, effectively resulting in the recovery of high-purity neodymium and dysprosium metals.

The results from the implementation of the SEEE process are striking. Achieving recovery rates of 96% for Nd and 91% for Dy, with purities exceeding 90%, underscores the method’s potential to outperform traditional recycling techniques. This level of efficiency signifies not only a breakthrough in materials recovery but also a substantial reduction in the environmental footprint associated with REE extraction.

The implications of these findings are profound, especially as the world grapples with the dual challenge of meeting rising demand for green technologies while simultaneously striving to minimize ecological impacts. The SEEE process opens doors for a more sustainable supply chain of rare-earth elements, thereby diminishing the reliance on new mining ventures that are notorious for their detrimental environmental consequences.

Moreover, the adaptability of the SEEE process extends beyond the recycling of neodymium magnets. Researchers are optimistic about its application in other sectors, including the reprocessing of nuclear fuels, underscoring its versatility and potential impact on a broader scale.

While the SEEE process demonstrates enormous promise, the road ahead is not without its hurdles. Researchers concede that additional technical investigations are required to seamlessly integrate this method into industrial practices. The transition from laboratory success to large-scale application is fraught with challenges that must be addressed to realize the full potential of this groundbreaking approach.

As we advance toward a future characterized by environmental sustainability and technological progress, innovative recycling methods like the SEEE process are essential. By effectively overcoming the barriers associated with rare-earth element recycling, this pioneering technique aligns seamlessly with global objectives for carbon neutrality and resource conservation.

The strides made in REE recycling through the SEEE process represent a beacon of hope in the quest for sustainable technology. As the demand for electric vehicles and renewable energy continues to soar, the imperative for efficient recycling solutions becomes ever more critical. The results from Kyoto University’s research not only highlight significant advancements in material recycling but also serve as a vital reminder of the role that cutting-edge research plays in shaping a sustainable future. Innovations like the SEEE process are not merely enhancements to existing technologies; they are essential steps in the transition towards a cleaner, greener world.

Leave a Reply