The world of robotics is increasingly moving towards systems that emphasize safety, adaptability, and flexibility, challenging the traditional notion of rigid machines. At the forefront of this evolution are Fabric-Based Soft Pneumatic Actuators (FSPAs), which leverage the principles of soft robotics to achieve unique functionalities. These innovative mechanisms operate by inflating or deflating, allowing them to bend, twist, and stretch in response to applied pressure. Their inherent softness not only enables them to safely interact with humans but also facilitates delicate tasks without risking injury or damage. Applications of FSPAs range widely, from wearable technology and assistive devices to specialized robotic grippers adaptable for various shapes and environments.

Despite their promising applications, the design and manufacture of FSPAs is fraught with challenges. Traditional pneumatic actuator designs often rely on isotropic materials—those that exhibit uniform properties in all directions. While this uniformity streamlines inflation and deformation, it significantly limits the creative potential of these actuators. Many existing designs require extensive trial and error to determine effective material configurations, creating hurdles in terms of both time and resources. Researchers have recognized an urgent need for innovative methodologies that would simplify this process, yielding FSPAs capable of executing complex movements without necessitating complicated, expensive materials.

Groundbreaking research conducted by a multidisciplinary team, including key figures from Toyota Central R&D Labs and Toyota Motor Engineering & Manufacturing North America, has proposed the use of Turing patterns—intricate designs inspired by Alan Turing’s mid-20th century morphogenesis theory. Turing’s work elucidated how patterns such as stripes on animals can arise from simple systems of reaction and diffusion, where substances interact dynamically to create stability in patterns. Drawing from this theory, the research team implemented a gradient-based orientation optimization method to advance the design of FSPAs, effectively allowing them to create textures that can morph based on pneumatic input.

This innovative approach opens up new avenues for creating bespoke actuator shapes that perform controlled movements with remarkable precision. By utilizing Turing patterns, researchers can manipulate the arrangement of fabrics on the surface of actuators in a way that enhances their functionality without increasing complexity.

The research team’s methodology begins with optimizing the orientation of the fabric used in FSPAs. They employed the nonlinear finite element method to meticulously align the fibers for optimal performance. This step is crucial for ensuring that the actuator behaves predictably as it responds to pneumatic pressure. Using mathematical models derived from anisotropic reaction-diffusion systems, the team has successfully generated complex pattern layouts that dictate how the fabric deforms and responds—integrating science and art within the engineering realm.

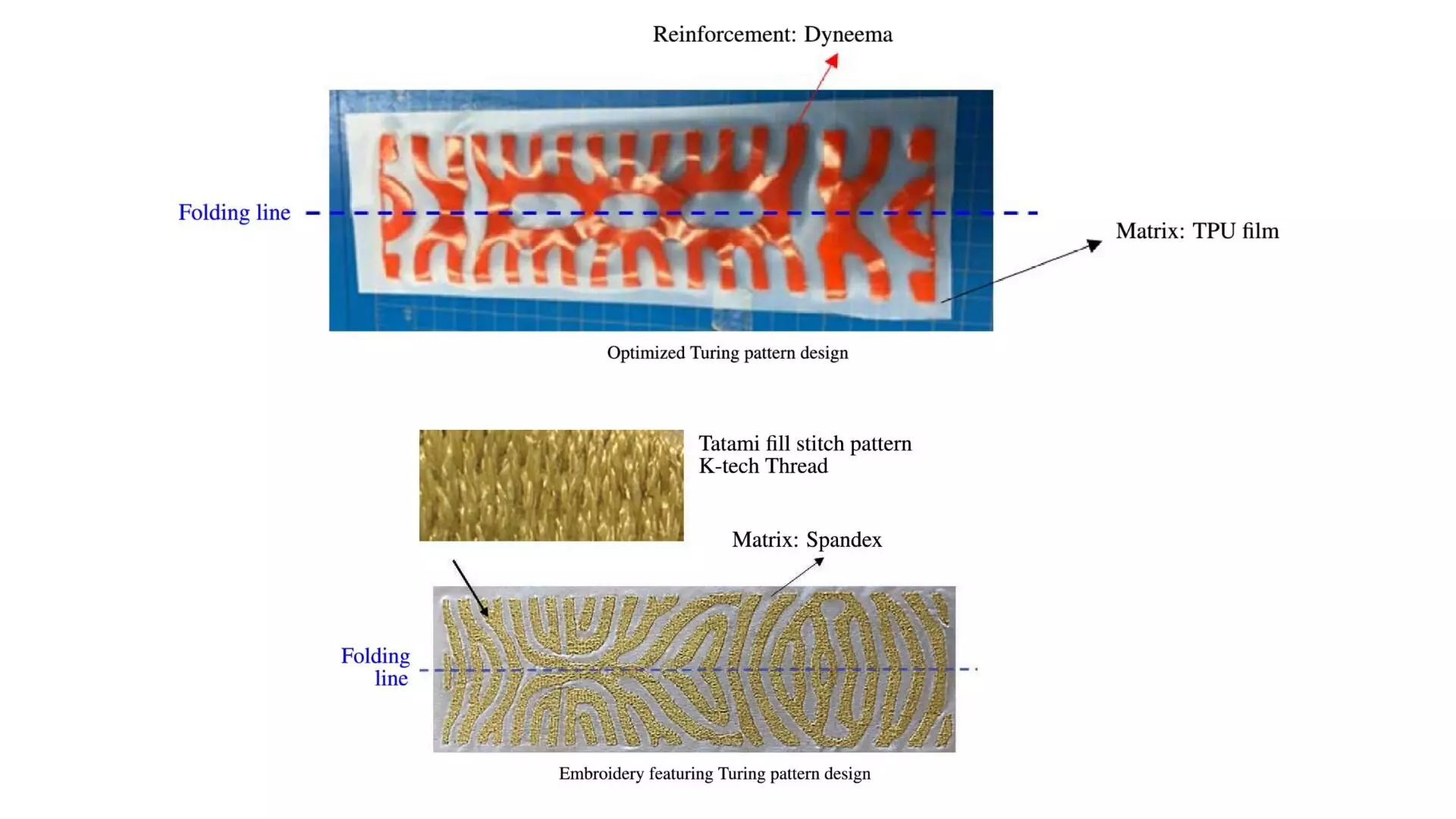

The actual manufacturing of these advanced FSPAs involves two main techniques: heat bonding and embroidery. In the heat bonding process, a sturdy fabric is carved into intricate Turing patterns and joined with softer materials using heat, creating a composite actuator. Meanwhile, the embroidery method infuses stiffness into soft fabric via stiff threads, further diversifying the regions of elasticity and control within the actuator.

The results from comparative tests between the newly designed Turing pattern FSPAs and traditional designs indicate promising performance improvements. Specifically, the Turing pattern configurations demonstrated enhanced effectiveness in C-shaped designs, reducing actuator edge distances notably. This performance leap illustrates a significant advantage for these novel actuators, providing a viable pathway for further integration into practical robotics.

While the current research has laid a strong foundation, the journey does not end here. Future investigations may delve into merging Turing patterns with advanced materials such as shape memory alloys or electroactive polymers, which could expand the capabilities of FSPAs, enabling them to achieve even more intricate motions. Additionally, researchers are looking towards scalable fabrication processes, potentially leveraging technologies like 3D printing and automated weaving to meet burgeoning demands for production and customization in soft robotics.

With Turing patterns offering a new frontier in the design of Fabric-Based Soft Pneumatic Actuators, the future of soft robotics appears to be bright and filled with potential. By combining innovative mathematical modeling with practical manufacturing techniques, researchers are not just pushing the boundaries of actuator technology—they are redefining the possibilities of flexible and safe robotic interactions in various sectors of society. As these technologies advance, we can envision a world where robots seamlessly coexist and collaborate with humans in versatility, safety, and efficiency.

Leave a Reply