As the textile industry grapples with the environmental consequences of fast fashion, innovative solutions are emerging from research institutions dedicated to sustainability. A recent breakthrough from a Cornell University research group led by Professor Juan Hinestroza introduces a promising technique to create waterproof coatings for clothing using discarded textiles. This approach not only prioritizes human and environmental health but also challenges the traditional reliance on harsh chemical treatments often associated with fabric waterproofing.

The textile industry has long used various synthetic coatings that effectively repel water but come with significant environmental and health risks. These traditional coatings frequently contain harsh chemicals and carcinogens, posing dangers to both workers involved in their production and consumers. It is estimated that Americans dispose of 80 to 100 pounds of clothing per person each year, contributing immensely to landfill waste. Transforming this pattern into a more sustainable model is critical, not only to mitigate environmental harm but also to promote a circular economy within the apparel sector.

A Greener Approach to Creating Waterproof Textiles

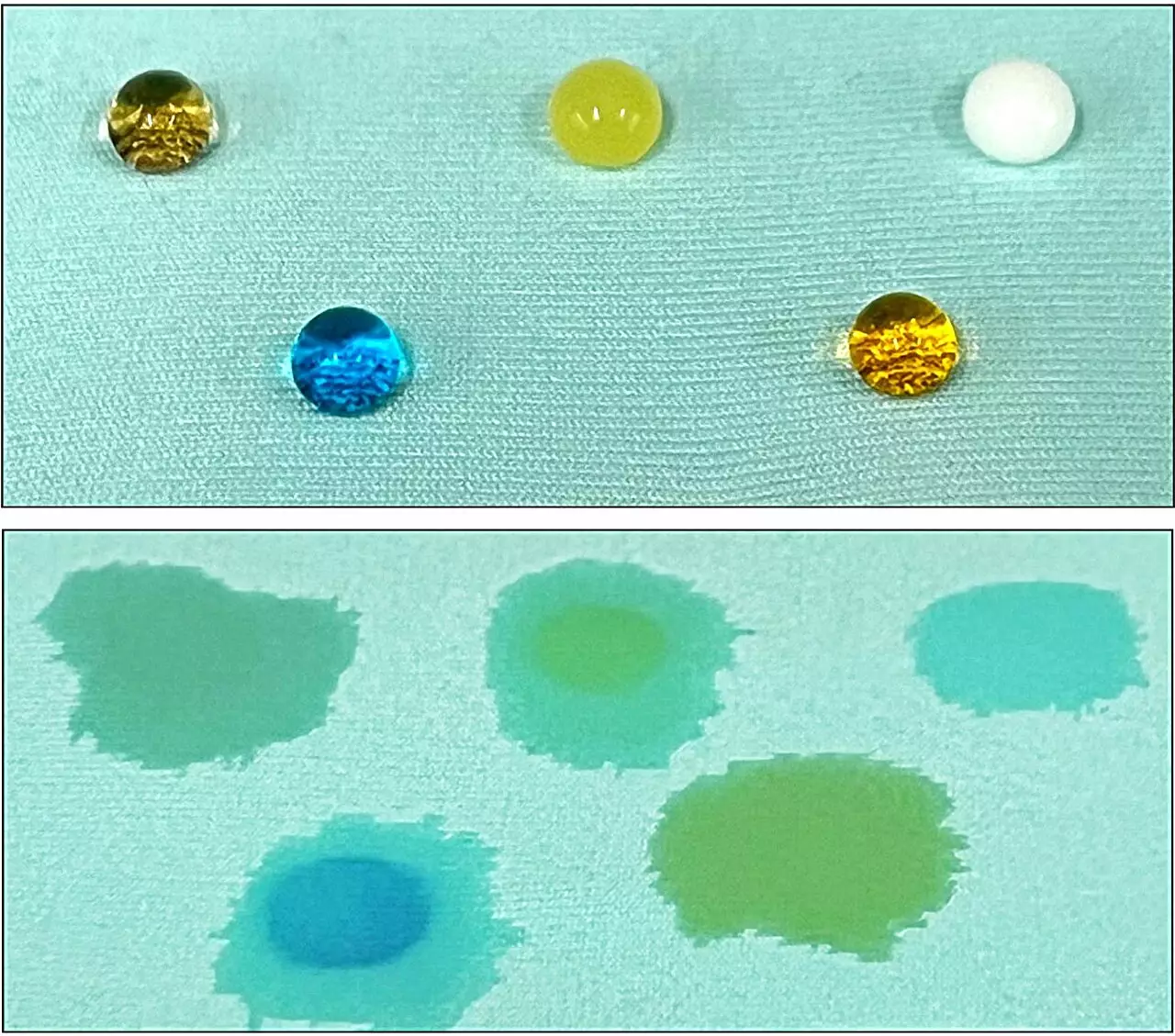

The innovative technique developed by Hinestroza and his team is grounded in the synthesis of metal-organic frameworks (MOFs), a class of compounds that can be tailored for specific functions, such as superhydrophobicity or water repellency. Unlike traditional methods that require high temperatures or toxic solvents, this novel process operates at room temperature and employs environmentally friendly solvents like water and ethanol. This method circumvents the need for energy-intensive separation or purification of discarded textile materials, laying the groundwork for a more sustainable approach to fabric treatment.

In their recent study published in ACS Applied Materials and Interfaces, doctoral student Yelin Ko and co-authors explored how to extract and repurpose polyester from discarded clothing. By applying an alkaline depolymerization process, the team broke down polyester textiles into a molecular mixture that retained dyes and additives. This mixture served as a feedstock for creating MOFs, specifically UiO-66, known for its robust structure and functional versatility.

The research revealed that the incorporation of spandex fragments altered the hydrophilic nature of the MOF, resulting in a superhydrophobic coating. Notably, this new coating maintained its waterproof characteristics even after rigorous washing and abrasion tests, confirming its durability. This advancement opens new avenues for producing textiles that resist moisture without the detrimental effects associated with traditional chemical treatments.

Addressing “Forever Chemicals” in Textile Manufacturing

A crucial aspect of this research is its potential to minimize reliance on fluorinated finishes, commonly referred to as “forever chemicals” due to their persistence in the environment and human body. Associate Professor Tamer Uyar emphasized the importance of this shift, stating that the study highlights the possibility of achieving functional qualities like water repellency and self-cleaning properties through the upcycling of textile waste. Thus, this research prompts the industry to rethink conventional practices by substituting harmful chemicals with sustainable alternatives.

Consumption Patterns and Sustainable Change

Hinestroza whimsically noted that while the focus often lies on the manufacturers, the real power for change rests with consumers. If consumers prioritize sustainable choices and demand eco-friendly products, brands will inevitably align their offerings with this new, conscious mindset. This dynamic relationship underscores the need for both innovation in textile treatments and a shifting perspective on consumption practices to reduce excess waste and promote sustainability.

Through their groundbreaking research, Hinestroza and his team present a forward-thinking solution that aligns with the urgent need for eco-friendly textiles. By transforming discarded textiles into waterproof coatings, they not only address prevalent environmental issues but also inspire a potential paradigm shift within the textile industry. The success of this initiative could pave the way for broader adoption of similar upcycling techniques, ultimately paving the road toward a more sustainable and responsible future for fashion. As the demand for sustainable practices grows, innovations like these may define the next chapter in the evolution of textile manufacturing.

Leave a Reply