In the modern world, plastic has become an essential part of our daily lives. However, the environmental impact of traditional plastic production and disposal is undeniable. The majority of plastics are derived from non-renewable resources such as crude oil, contributing to pollution and resource depletion. As a result, there is a growing urgency to find sustainable alternatives that can mimic the desirable properties of conventional plastics without the detrimental environmental effects.

A groundbreaking development from Kobe University involves the use of engineered bacteria to produce a plastic modifier known as LAHB. This modifier enhances the properties of polylactic acid, a bioplastic derived from plants. By mixing polylactic acid with LAHB, the researchers were able to create a material that is more robust, processable, and biodegradable even in seawater. This achievement opens up possibilities for creating a new generation of environmentally friendly bioplastics that can potentially revolutionize the plastic industry.

To produce LAHB, the researchers utilized bioengineering techniques to manipulate the genome of bacteria. By introducing new genes and eliminating interfering ones, they successfully created a bacterial strain capable of producing high amounts of LAHB chains using glucose as a feedstock. By controlling the length of the LAHB chains through genome modification, the researchers were able to optimize the properties of the resulting plastic. This innovative approach resulted in the production of “ultra-high molecular weight LAHB,” which significantly improved the characteristics of the final bioplastic material.

The benefits of utilizing engineered bacteria for plastic production extend beyond just creating a more environmentally friendly material. The bacterial strain developed in this study has the potential to utilize CO2 as a raw material, offering a sustainable way to synthesize plastics directly from greenhouse gases. This opens up new avenues for reducing carbon emissions and developing eco-friendly manufacturing processes in the plastic industry.

The Future of Bioplastics

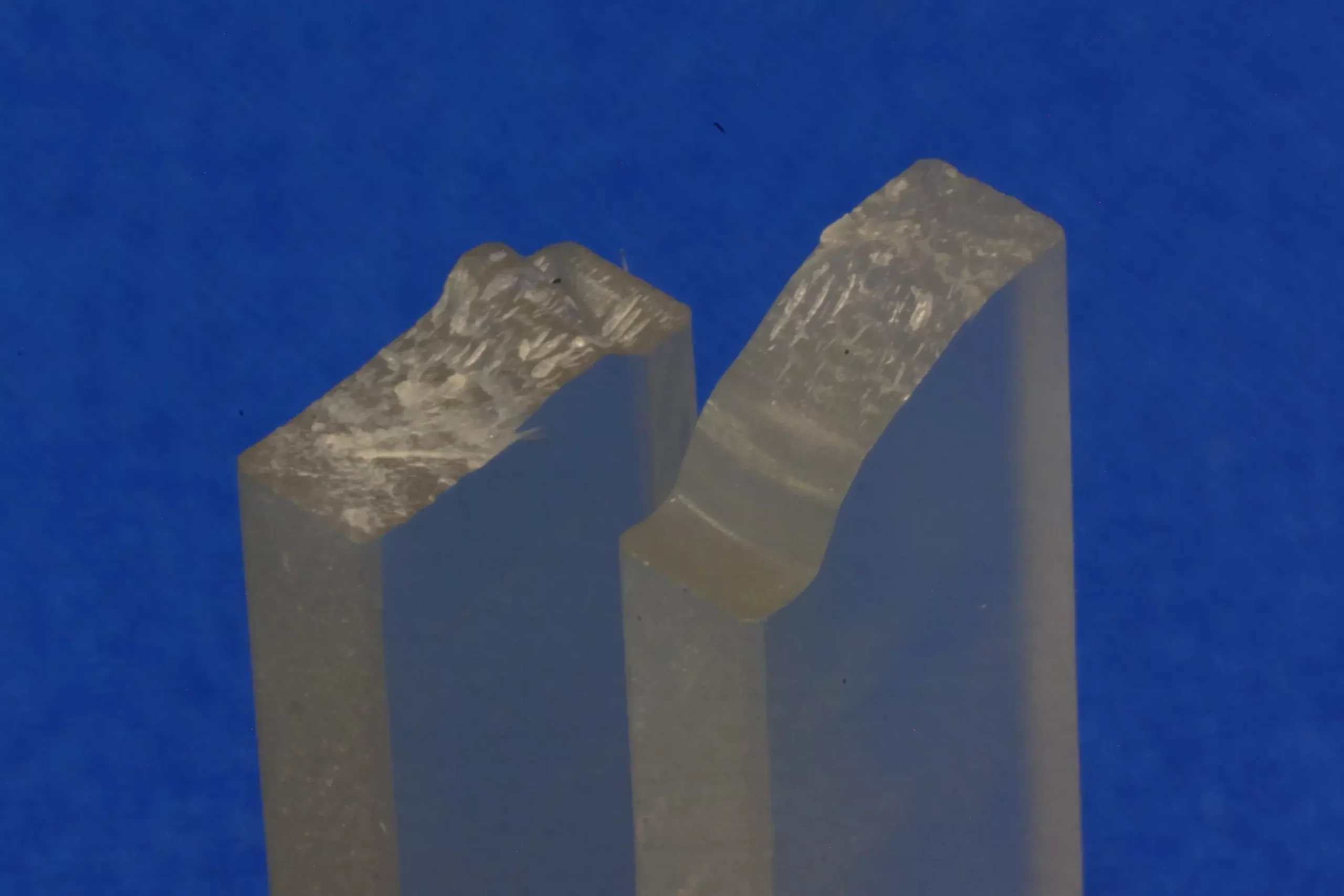

The successful creation of a highly transparent, moldable, and biodegradable bioplastic material by blending polylactic acid with LAHB is a significant step towards achieving a more sustainable plastic industry. With the ability to address the conflicting needs of physical robustness and biodegradability in a single material, the researchers have demonstrated the potential for environmentally sustainable bioplastics that can meet the demands of modern society.

The innovative use of engineered bacteria in the production of bioplastics represents a promising solution to the environmental challenges posed by traditional plastics. By harnessing the power of biotechnology, researchers are paving the way for a greener and more sustainable future for the plastic industry.

Leave a Reply