Biocatalysis has long been recognized as a promising field for the development of biotechnological processes that enable the recycling of plastics. However, the lack of knowledge about the molecular mechanisms underlying biocatalysis has hindered progress in this area. In a groundbreaking research project led by a team from the Universitat Jaume I, a new approach to recycling widely used PET plastics was discovered. By modifying the pH of the medium, the team successfully utilized a natural enzyme, CALB, to degrade PET plastics and generate harmless compounds suitable for subsequent synthesis processes. This discovery opens up new possibilities for the efficient and environmentally friendly recycling of PET plastics, which are commonly found in various applications such as containers, bottles, and textiles. The results of this study were published in the esteemed journal Nature Communications.

Plastics, including PET, possess desirable properties that have contributed to their extensive use in diverse applications. However, the very durability that makes plastics appealing also presents a challenge for their recycling. Unlike natural materials, synthetic polymers like PET have not existed for a sufficient period of time for evolutionary processes to develop enzymes capable of degrading them. Consequently, researchers face the daunting task of finding efficient and environmentally-friendly means of recycling plastics without causing further harm to the environment.

The research team at the Institute of Advanced Materials (INAM) of the UJI, led by Vicent Moliner and Katarzyna Świderek, approached this problem using computational biochemistry. As computational chemists, they employed theoretical simulations to make predictions about the behavior of enzymes on plastics. The experimental part of the project was conducted by a group from the Center for Cooperative Research in Biomaterials (CIC biomaGUNE) of the Basque Country, led by Fernando López Gallego, and another group from the University of the Basque Country, led by Haritz Sardon. The collaboration between these groups proved essential in bridging the gap between theoretical predictions and practical application.

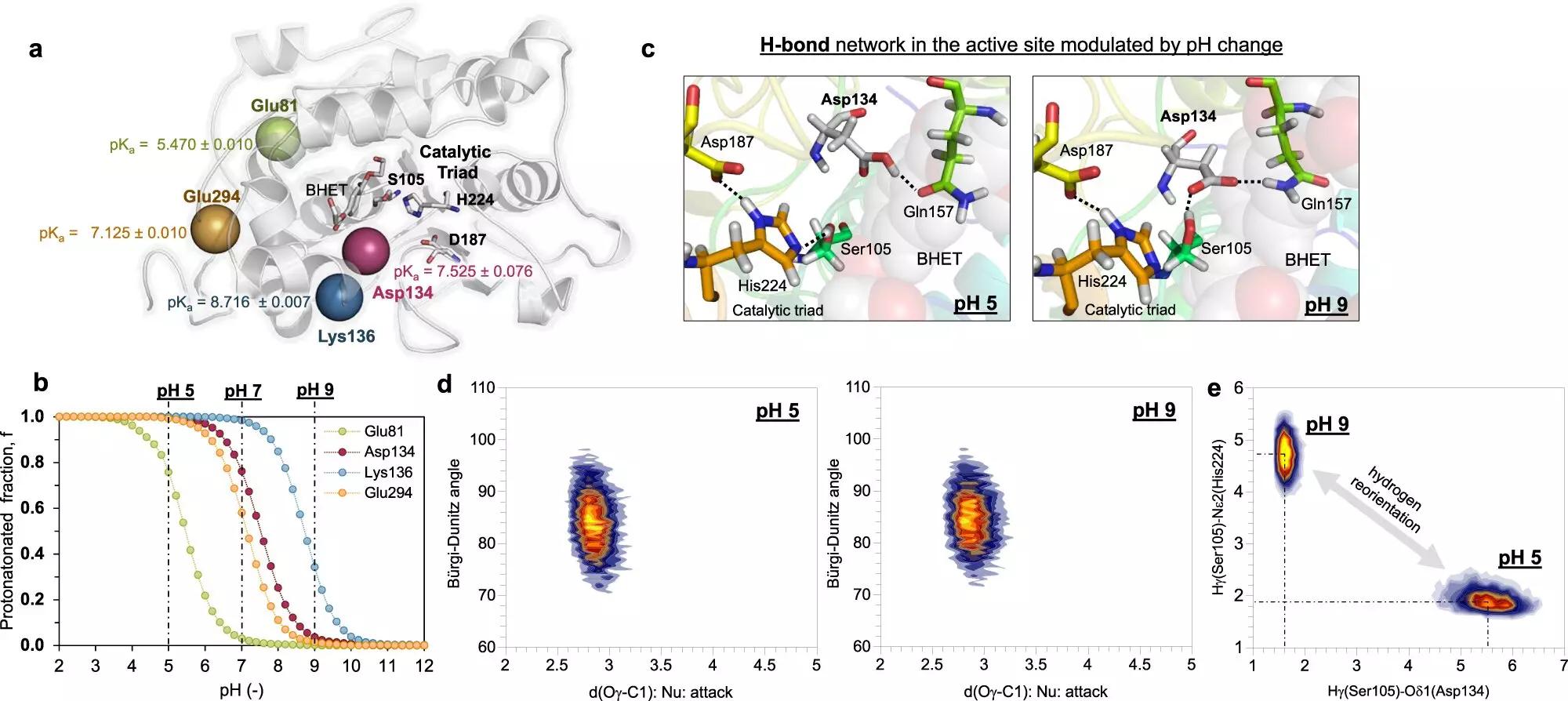

The study centered around the use of the CALB enzyme, a naturally occurring enzyme known for its ability to catalyze multiple reactions. Through their computational simulations, the team discovered that CALB had the potential to degrade PET plastics. However, the breakthrough came when they realized that by modifying the pH of the medium, they could alter the enzyme’s structure and obtain two unique types of products that are typically challenging to synthesize through traditional methods. This finding not only demonstrated the potential of CALB for PET plastic degradation but also highlighted the ability to control the reaction’s end products by simply adjusting the pH.

While the discovery of CALB’s potential for PET plastic degradation is a significant achievement, the research team acknowledges that there is still much to explore and improve upon. The next step involves delving deeper into the study to enhance the reaction’s speed by redesigning the enzyme. Additionally, the team aims to expand their research to other types of synthetic polymers, such as polyurethanes, which are widely used. Collaboration with research groups in Sweden and Denmark will help advance these efforts and further contribute to the field of biocatalysis.

The breakthrough discovery of PET plastics recycling through the utilization of the CALB enzyme and pH modification represents a significant advancement in biocatalysis. This development opens up new possibilities for the efficient and eco-friendly recycling of PET plastics, which is essential for reducing environmental pollution. The collaboration between computational biochemistry and experimental research has allowed for the translation of theoretical predictions into practical applications. With continued research and improvement, the potential of enzyme-based recycling processes for various synthetic polymers is within reach, promising a more sustainable future for the plastics industry.

Leave a Reply