For centuries, scientists have grappled with the challenge of growing dolomite, a common mineral found in various geological formations. However, thanks to a groundbreaking new theory developed through atomic simulations, a team of researchers from the University of Michigan and Hokkaido University in Sapporo, Japan has successfully grown dolomite in the lab. This milestone achievement not only solves the long-standing “Dolomite Problem” but also opens doors to new possibilities in crystal growth for modern materials.

Dolomite, a crucial mineral found in prominent locations such as the Dolomite mountains in Italy, Niagara Falls, the White Cliffs of Dover, and Utah’s Hoodoos, is abundant in rocks older than 100 million years. However, it becomes scarce in younger formations, posing a perplexing geological puzzle. To understand the growth process of dolomite in nature and potentially apply it to the development of advanced technological materials, it was essential to overcome the challenges that hindered its successful lab cultivation.

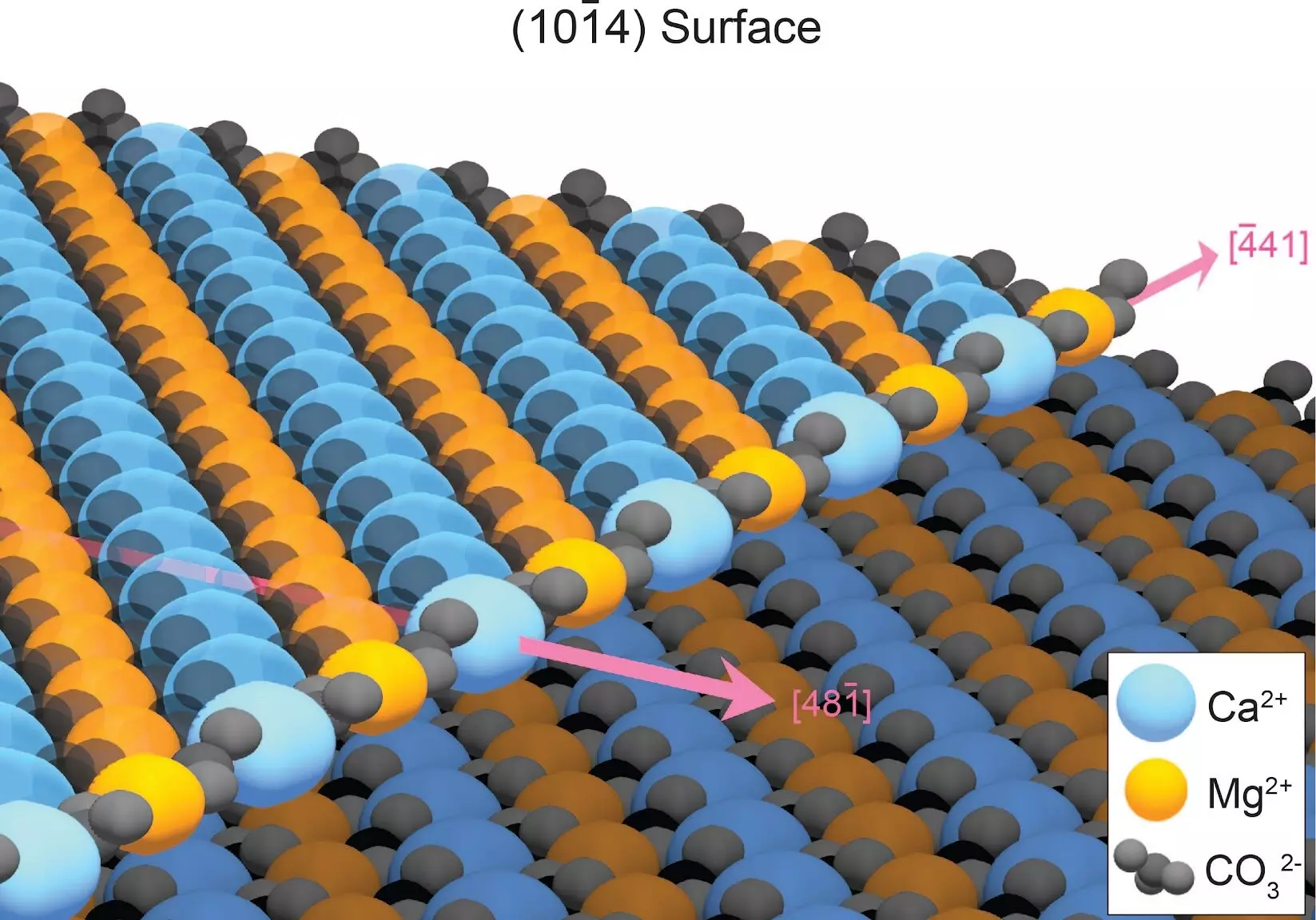

Through extensive research, the team discovered that defects in the mineral structure were the primary obstacles to dolomite growth. While typical mineral formation involves atoms neatly depositing onto the crystal surface, the growth edge of dolomite consists of alternating rows of calcium and magnesium. This alternating arrangement often leads to calcium and magnesium atoms attaching randomly to the growing crystal, creating defects that prevent the formation of additional dolomite layers. Consequently, the disorder significantly slows down the growth process of dolomite, making it virtually impossible to form ordered layers in a reasonable timeframe.

However, the team found that these defects were not permanent. As the disordered atoms are less stable than those in the correct positions, they dissolve first when the mineral is washed with water. Natural processes such as rain or tidal cycles repeatedly rinsing away these defects allow for the formation of a dolomite layer within a matter of years. Over geological time, this repeated cycle leads to the accumulation of mountains of dolomite.

To accurately simulate dolomite growth, the researchers needed to calculate the strength of attachment between atoms and an existing dolomite surface. These calculations typically require immense computing power due to the requirement of analyzing every single interaction between electrons and atoms within the crystal. However, the team developed specialized software at the University of Michigan’s Predictive Structure Materials Science (PRISMS) Center, which expedited the process.

The software employed a shortcut by calculating the energy for certain atomic arrangements and extrapolating those energies for other arrangements based on the crystal structure’s symmetry. This innovation significantly reduced the computational requirements, making it feasible to run simulations of dolomite growth over geologic timescales. What previously took thousands of hours on a supercomputer now takes mere milliseconds on a desktop computer, revolutionizing the capabilities of crystal growth simulations.

While the theory provided a compelling explanation for dolomite formation, additional evidence was needed to fully confirm its validity. Yuki Kimura, a materials science professor from Hokkaido University, and Tomoya Yamazaki, a postdoctoral researcher in Kimura’s lab, devised an ingenious experiment utilizing transmission electron microscopes. Electron beams used for imaging samples can also split water and create acid that dissolves crystals. In this case, the desired outcome was precisely the dissolution of defects.

Using this technique, the researchers placed a tiny dolomite crystal in a calcium and magnesium solution and gently pulsed the electron beam 4,000 times over a span of two hours. The repeated pulses successfully dissolved away the defects, allowing for the growth of approximately 100 nanometers of dolomite. While this may seem insignificant in terms of size, it represented a groundbreaking achievement as it surpassed the previous record of growing only five layers of dolomite in a lab setting.

The knowledge gained from unraveling the Dolomite Problem has far-reaching implications for material engineering in various industries. Crystal growers striving to produce defect-free materials previously pursued slow growth as a means to achieve their goal. However, the new understanding of dolomite growth presents an alternative approach. By repeatedly rinsing away defects through controlled means, engineers can expedite the growth process while maintaining top-quality materials.

This newfound knowledge can empower the manufacturing of higher-quality materials for semiconductors, solar panels, batteries, and other technological applications. By leveraging the insights gained from solving the Dolomite Problem, scientists and engineers have the potential to revolutionize the development of modern materials, paving the way for more efficient and advanced technologies.

Pioneering research conducted by the University of Michigan and Hokkaido University has successfully addressed the Dolomite Problem, a longstanding geological mystery. Through innovative techniques and atomic simulations, scientists have finally overcome the challenges of growing dolomite in the laboratory. This breakthrough not only sheds light on the natural formation of minerals but also provides crucial insights into crystal growth for cutting-edge materials. As scientists continue to explore the possibilities unlocked by this breakthrough, the future of technological advancements looks brighter than ever before.

Leave a Reply