Have you ever imagined a material that defies common sense by becoming wider and fatter when pulled and thinner when pushed? Such materials are not just a product of imagination, they actually exist and are known as auxetics. These unique materials have properties that make them suitable for a wide range of applications, from bomb-resilient buildings to comfortable clothing and everything in between. Despite the great potential of auxetic products, they have been slow to make their way to the market.

Researchers at the National Institute of Standards and Technology (NIST) and the University of Chicago have developed a groundbreaking new tool that aims to change the game for auxetic materials. In a recent study published in npj Computational Materials, they introduced an algorithm that simplifies and accelerates the process of designing materials with auxetic properties. With this tool, precise three-dimensional design of auxetics is now possible, opening up a world of possibilities for their practical applications.

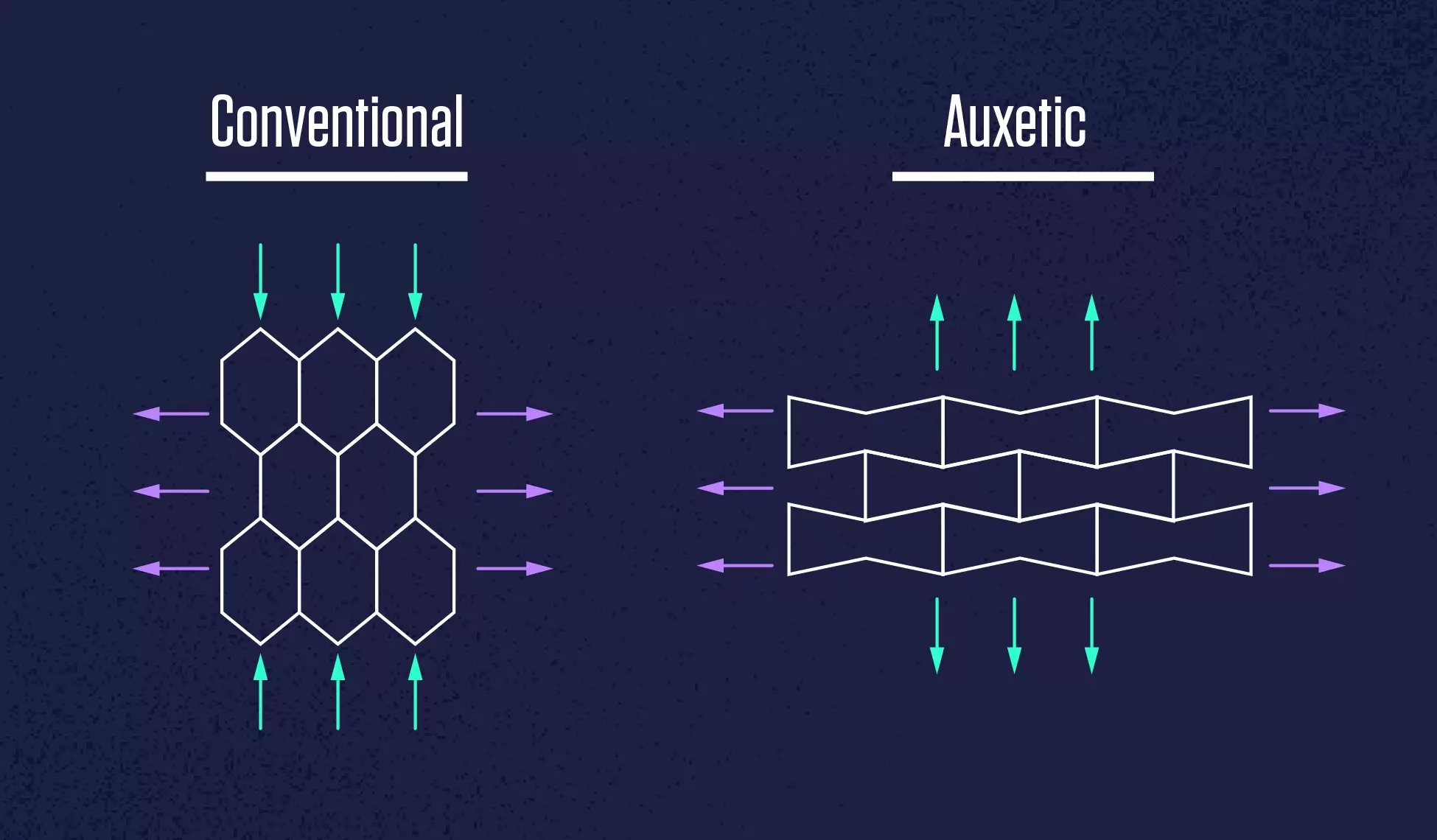

The behavior of elastic materials, including auxetics, is characterized in part by Poisson’s ratio. This ratio describes how a material changes shape when stretched or squeezed in one direction. Most materials have a positive Poisson’s ratio, meaning they become wider or thicker when compressed and narrower or thinner when stretched. Auxetics, on the other hand, have a negative Poisson’s ratio, causing them to behave in the opposite manner. This unique property gives auxetic materials a range of advantages, including increased impact resistance and pressure distribution capabilities.

The potential applications of auxetic materials are vast and diverse. From bomb-resilient buildings to shock-absorbing car bumpers, auxetics offer enhanced protection from explosions and collisions. In the world of footwear, auxetic insoles made from gel or rubber foam could provide superior cushioning for the feet. In clothing, auxetic nylons and fibers offer a more comfortable and pressure-relieving alternative to traditional materials.

The newly developed design tool by NIST and University of Chicago researchers is based on an “inverse design” algorithm. Users can input their desired value for the material’s Poisson’s ratio, and the algorithm will generate an optimized structure accordingly. This approach allows for precise control over the behavior of auxetic materials, paving the way for innovations that were previously thought to be beyond the realm of natural materials.

The research conducted by the NIST and University of Chicago team represents a groundbreaking advancement in the field of auxetic materials. By creating a tool that enables the efficient design of auxetic structures, they are opening up new possibilities for the use of these materials in everyday life. With patents secured for their algorithm and methodology, the future looks bright for the widespread adoption of auxetics in various industries.

Leave a Reply