In recent developments in the field of additive manufacturing, researchers at the University of Nottingham have made significant strides in enhancing the functionality of plastic particles used in 3D printing. By utilizing supercritical carbon dioxide, a new coating process has been developed to improve the properties of PA-12 polymer particles commonly used in 3D printing.

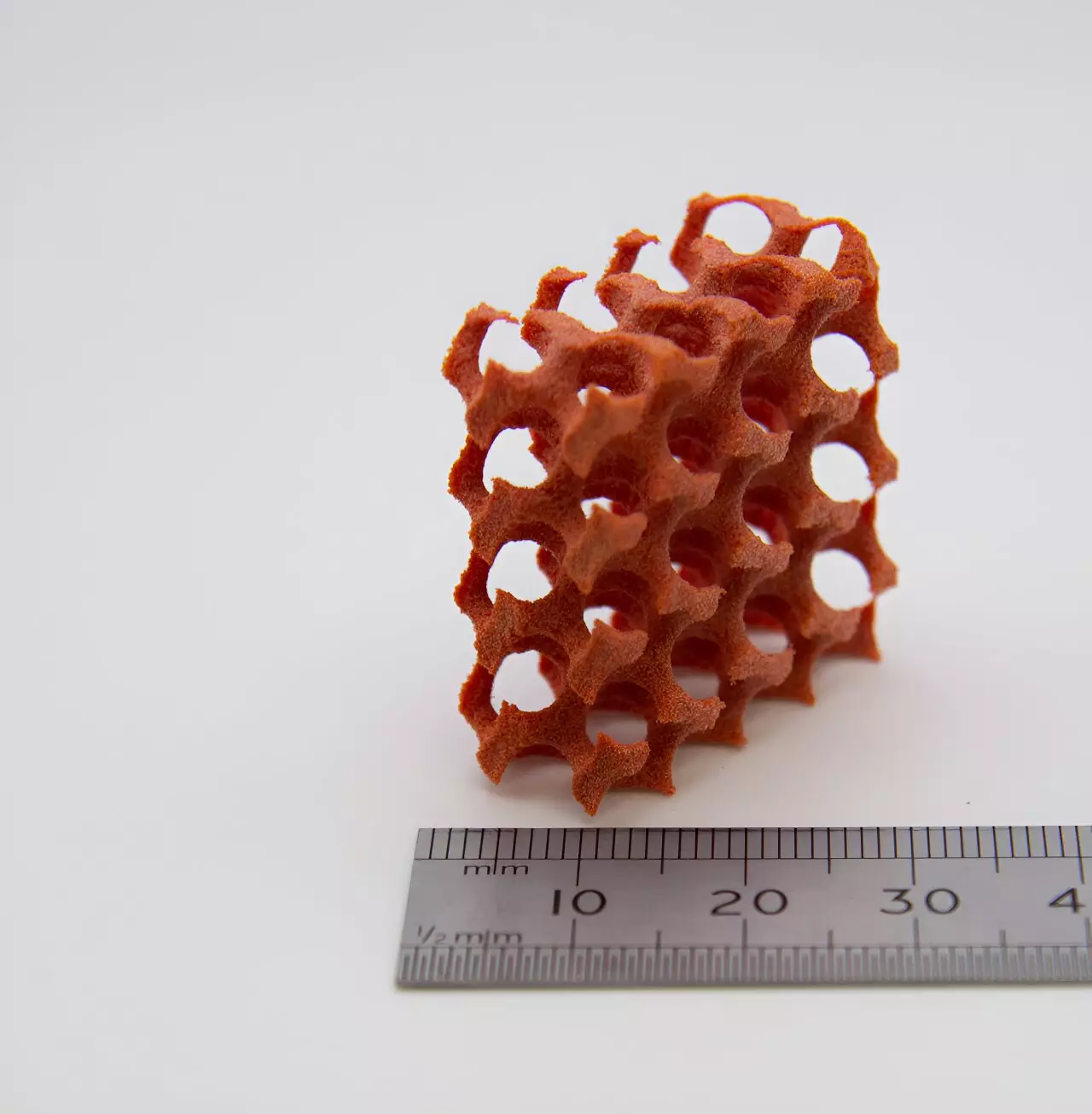

Traditional 3D printing techniques, such as powder bed fusion or laser sintering, involve the layer-by-layer deposition of polymer powder that is then melted together using a laser. While these methods have revolutionized the manufacturing industry, they are often limited by the materials and properties available for use.

The innovative coating process developed by the team at the University of Nottingham has the ability to add color, anti-mold, and anti-fungal properties to the 3D printing process. This breakthrough has been published in Nature Communications, showcasing the potential for a wider range of material capabilities without compromising the overall processability.

Professor Christopher Tuck, a leading expert in materials engineering, highlights the benefits of this new process in expanding the possibilities for manufacturers. By adding coatings to the PA-12 particles, the team has created a range of colored polymers that enhance the mechanical and thermal properties of the printing polymer. This allows for the production of bespoke and unique objects with added functionality.

The 3D printing industry has faced challenges in the past due to the limitations of available polymers. However, the new coating process offers a simple and effective solution to enhance functionality by coating the particles. Professor Steve Howdle, head of the School of Chemistry, emphasizes the importance of developing coatings that prevent the growth of mold and fungi, opening up new possibilities for the use of 3D printed objects in various environments.

The development of enhanced coatings for plastic particles used in 3D printing represents a significant advancement in additive manufacturing. The team at the University of Nottingham has paved the way for improved functionality and expanded material capabilities in the industry. With this breakthrough, the future of 3D printing looks brighter than ever, with endless possibilities for innovation and customization.

Leave a Reply