The demand for valuable metals used in batteries is anticipated to surge in the coming decades, driven by the growth of clean energy technologies. To meet this demand sustainably, recycling spent batteries may prove to be the best solution. Scientists at Rice University have developed an innovative battery recycling process that effectively removes the inert layer on battery metals, allowing for their efficient recovery. By utilizing their pioneering Joule-heating technique, the research team achieved a metal recovery yield exceeding 98% from various types of mixed battery waste. This groundbreaking method not only significantly reduces secondary waste streams but also drastically reduces the duration of the recycling process.

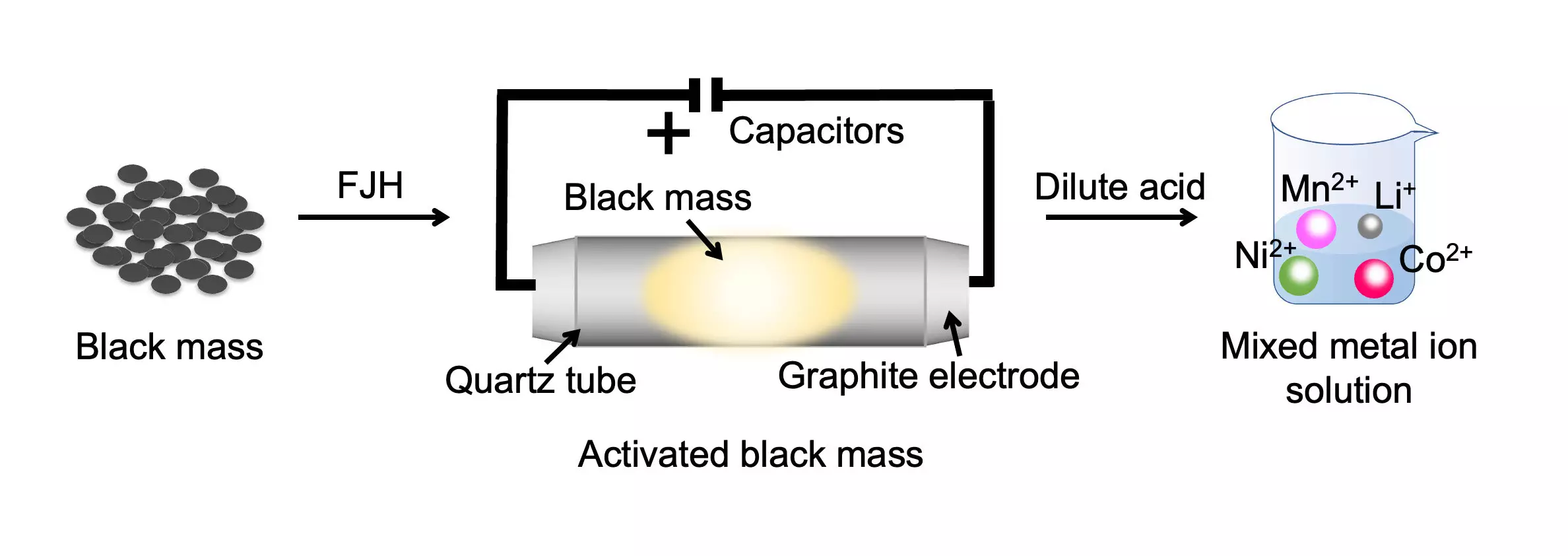

The traditional approach to recycling batteries involves the recovery of the combined cathode and anode waste, known as the “black mass.” However, this method has several limitations, including high costs, prolonged processing time, and environmental concerns. The newly developed technique by Rice University addresses these challenges head-on. By subjecting the battery waste to temperatures exceeding 2,100 degrees Kelvin within seconds, the process dissolves the passivated layer and regulates the metal valence state for the first time. This breakthrough allows for improved leaching kinetics and a more efficient recovery of valuable metals.

The adoption of this innovative battery recycling process has the potential to revolutionize the industry for several reasons. Firstly, it significantly reduces the environmental footprint associated with battery processing. By minimizing secondary waste streams and acidic leaching solutions, the method drastically reduces the carbon dioxide emissions and consumption of energy, water, and acid. Additionally, the recycling process is accelerated by almost 100-fold, with the dissolution of the same amounts achieved in under 20 minutes compared to the previous 24-hour duration.

Furthermore, recycling spent batteries is not only an environmentally responsible choice but also economically sound. The concentration of metals like cobalt and nickel is higher in many types of lithium-ion batteries compared to natural ores. As the demand for these metals increases, recycling presents an opportunity to extract them in a cost-effective manner. Currently, an overwhelming 95% of batteries are not recycled due to the lack of recycling capacity, despite the annual increase in electronic waste. By developing a more efficient and economical process, Rice University’s innovation could supercharge the battery recycling business and meet the growing demand.

The significance of battery recycling is particularly pronounced now, as the batteries powering electric vehicles (EVs) are reaching their end of life. EV batteries typically last around 10 years, meaning a surge of expired batteries is imminent. To reduce the environmental impact of mining for battery metals, recycling is essential. The new process developed by the Rice University research team offers a sustainable solution for meeting the demands of the EV industry and other electronic devices.

The flash liberates the critical metals within the black mass, allowing for their easy separation using low-concentration hydrochloric acid. This approach minimizes the reliance on strong acids, streamlining the recycling process and optimizing the economics of battery waste recycling. The research team’s findings have the potential to drive the growth of battery waste management, contributing to the mass production of electric vehicles at a more competitive cost.

The implications of Rice University’s battery recycling innovation are far-reaching. The ability to efficiently recover valuable metals from spent batteries reduces the need for environmentally damaging mining practices. With the demand for clean energy technologies on the rise, sourcing these metals through recycling presents a sustainable solution to meet future needs.

The next steps in advancing battery recycling involve scaling up the developed process and establishing robust recycling infrastructure. By building the capacity to recycle batteries effectively, the industry can maximize resource utilization and minimize waste. Additionally, further research and development efforts in battery design and composition can facilitate easier recycling and enhance the overall sustainability of energy storage solutions.

The future of battery recycling looks promising. Rice University’s breakthrough technique offers an efficient, cost-effective, and sustainable solution to recover valuable metals from spent batteries. As the demand for clean energy technologies continues to surge, battery recycling will play a crucial role in meeting these demands while minimizing environmental impact. With the right investments and support, battery recycling can become a thriving industry that contributes to a greener and more sustainable future.

Leave a Reply