The intersection between hard and soft materials has long been a challenge in various industries. From laptop chargers breaking at the cable-to-adapter joint to the failure of man-made materials in the human body, finding an effective interface has proven to be difficult. However, researchers from TU Delft have made significant strides in this field by utilizing a unique 3D printing process. In a recent study published in Nature Communications, the team successfully developed hybrid multi-material interfaces that closely resemble nature’s design of bone-tendon connections. This breakthrough has opened up numerous potential applications and has paved the way for future advancements in material engineering.

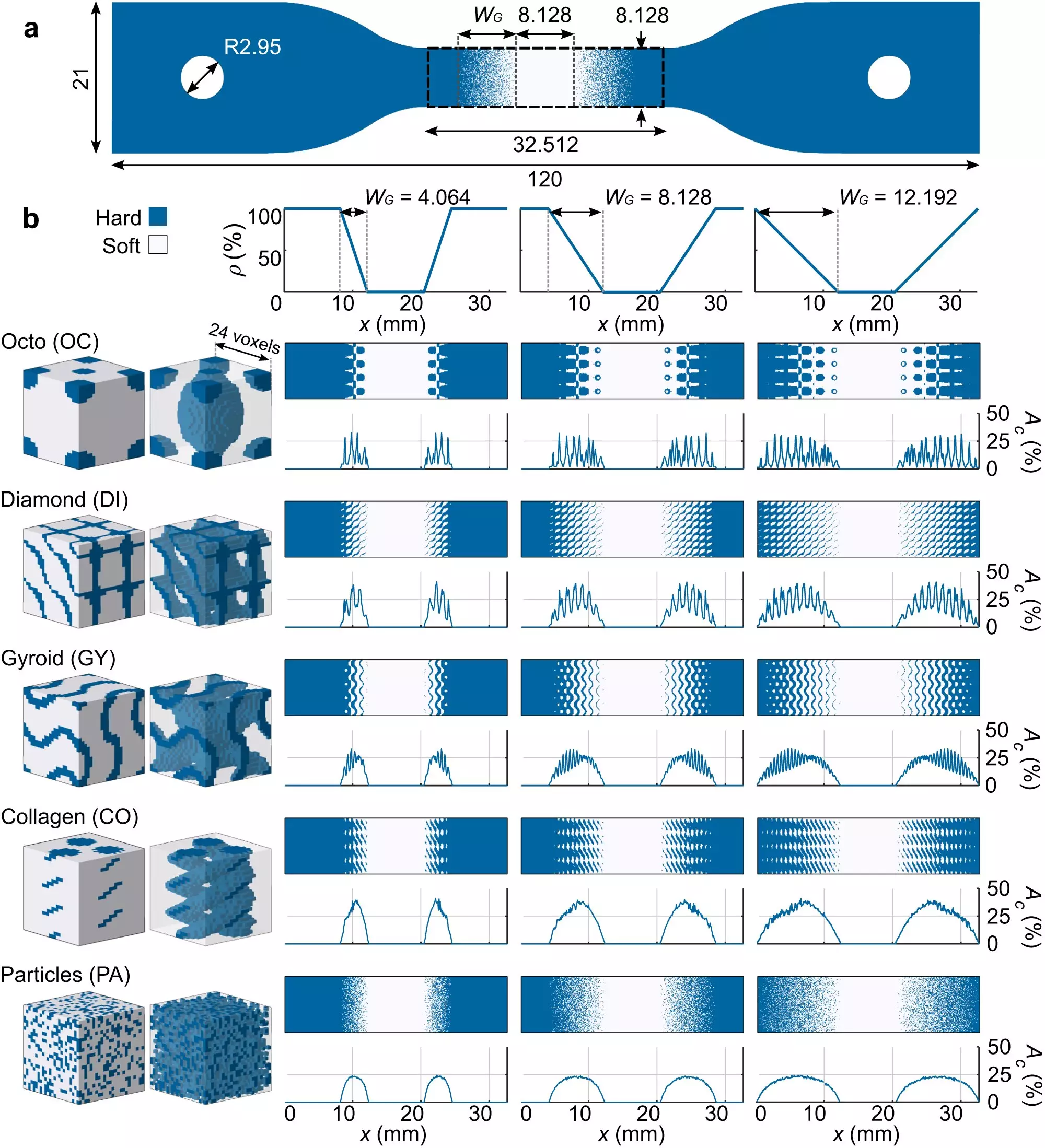

When materials with varying hardness are connected, stress concentration and subsequent failure of the softer material often occur. To overcome this issue, researchers led by Professor Amir Zadpoor from the faculty of Mechanical, Maritime, and Material Engineering (3mE) focused on emulating nature’s gradual change in properties at the interface. Nature doesn’t abruptly transition from a hard material to a soft one; rather, it smoothly transitions, mitigating stress concentration. By taking inspiration from this, the team employed different geometries and a multi-material 3D printing technique to increase the contact area between the hard and soft interfaces.

A key consideration in interface design is ensuring that the connection point exceeds the strength of the soft material. Creating an interface stronger than the soft material would be pointless, as the soft material would still fail, serving as the limiting factor. The researchers successfully enhanced the toughness values of interfaces by 50% compared to a control group. Pushing the boundaries of what is theoretically possible was one of the significant accomplishments of this study. Additionally, the research produced a set of design guidelines that can be universally applied to improve the mechanical performance of bioinspired soft-hard interfaces.

One of the most promising aspects of this research is the technique developed by the team, which allows for the creation of a complete product in one go. Traditionally, products with multiple materials are assembled or attached using adhesives, adding extra, time-consuming steps to the manufacturing process. However, the team’s innovation eliminates these additional steps, enabling the combination of even more exotic materials. This breakthrough holds immense potential for a wide range of applications, including medical devices, soft robotics, and flexible devices. Furthermore, the team intends to explore the integration of living cells into these interfaces to facilitate procedures such as connecting implants to the surrounding soft tissue. This complex integration of living cells would open up a new era of regenerative medicine and further enhance the capabilities of this technology.

The research conducted by TU Delft researchers has revolutionized the field of interface design. By closely emulating nature’s design, the team successfully developed hybrid multi-material interfaces that overcome the challenges of connecting hard and soft materials. This breakthrough has not only enhanced the mechanical performance of these interfaces but has also provided a framework of design guidelines that can be universally applied. The ability to create whole products in one go, utilizing the team’s novel 3D printing technique, has significantly streamlined manufacturing processes and expanded the range of materials that can be combined. The applications of this technology are vast, from medical devices to soft robotics. With the future integration of living cells into these interfaces, the possibilities are truly limitless. This research marks the beginning of a new era in material engineering and interface design, opening the door to a multitude of future studies and advancements in the field.

Leave a Reply