In today’s world, where waste generation has become a significant concern, finding sustainable alternatives to synthetic materials is of utmost importance. Plastic and petroleum-based materials contribute to a large portion of the waste that ends up in landfills, as they cannot decompose or degrade over time. This problem has led scientists to search for materials that are not only effective but also environmentally friendly. One such alternative is mycelial fibers, derived from mushroom bodies, which show immense potential for a variety of consumer and industrial applications.

Mycelial fibers, also referred to as root-like fruiting bodies of mushrooms, possess a unique set of properties that make them ideal for various applications. These fibers contain proteins, chitin, and polysaccharides, which give them excellent formability and durability. As a result, they can be used to manufacture packaging materials, soundproofing products, textiles, and more. Moreover, mycelial fibers have low environmental impact, are biodegradable, and can be produced at a relatively low cost.

While mycelial fibers offer great potential as sustainable materials, traditional methods of extraction have their limitations. Conventional chemical or mechanical treatments often result in undesired coloration and damage to the intricate mycelial structures, restricting their applications on a nanoscale level. Finding a simple and effective way to obtain mycelial fibers without compromising their structure has been a significant challenge.

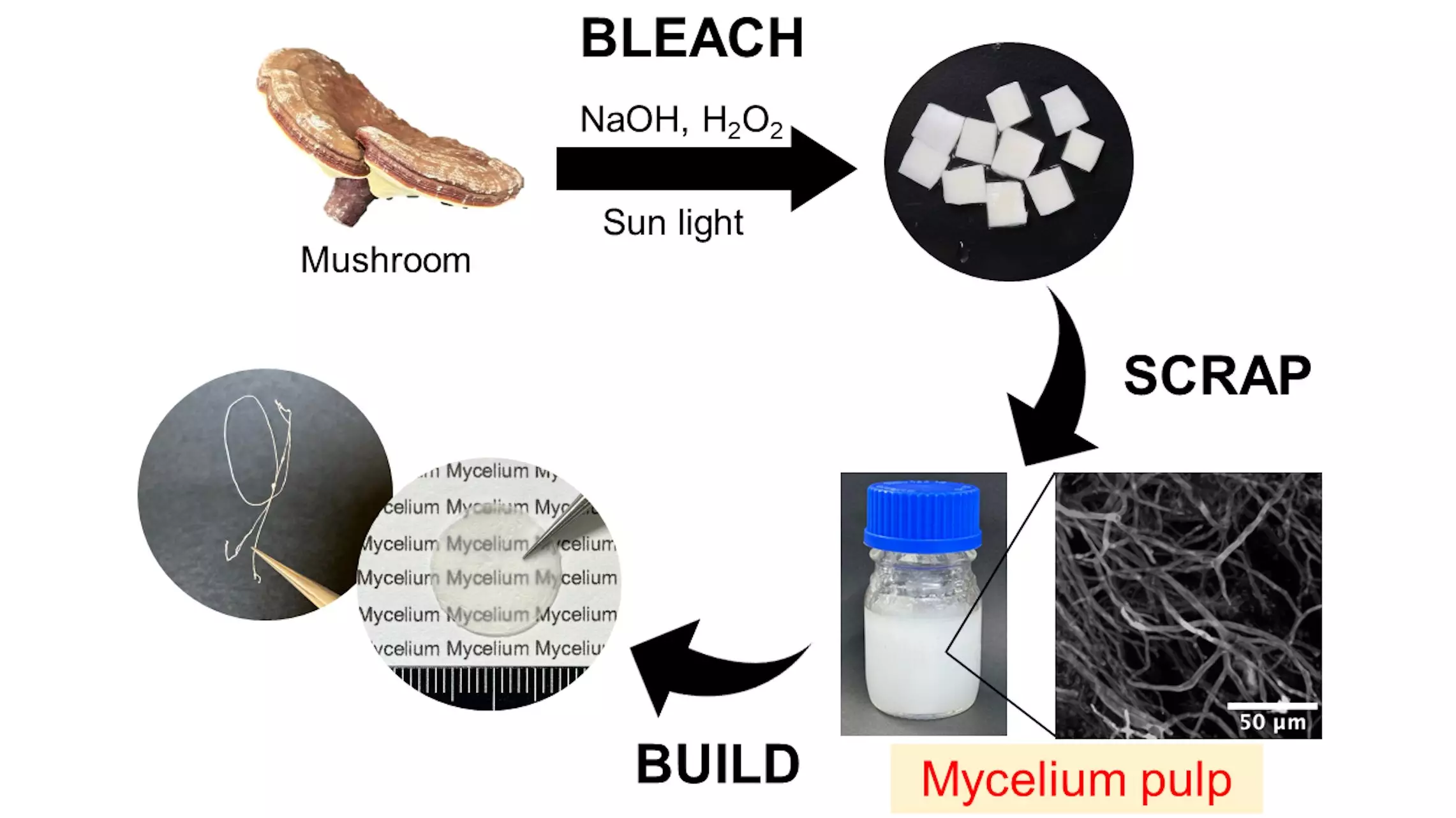

A recent study conducted by researchers from Shinshu University in Japan presents an innovative method of obtaining mycelial pulp and fibers while preserving their intricate structures. The team treated the fruiting bodies of enoki and reishi mushrooms with sodium hydroxide and hydrogen peroxide. The substances obtained were then bleached using sunlight. This process transformed the materials into a white pulp, which was further defibrillated at a mycelial level through ultrasonic treatment. As confirmed by Fourier-transform infrared spectroscopy, the resulting dispersion contained micrometer-sized mycelium fibers with intact structures.

The mycelial fibers obtained through this novel approach exhibit excellent deformability, making them suitable for various design applications. These fibers can be used to create 3D porous sponges, 2D films, and 1D yarns, expanding the range of possibilities for mushroom-based materials. The simplicity of this extraction method adds value to the existing scrap-and-build approach, enhancing the overall fabricating process. By upcycling by-products generated by the mushroom industry, this technology promotes circularity and enables easier reuse of mushroom materials.

The development of sustainable materials and methods, such as the extraction of mycelial fibers, has the potential to create new industries, generate employment opportunities, and revitalize local communities. By harnessing the power of mushrooms and incorporating them into everyday household items, consumers can make choices that are safe, reliable, and environmentally friendly. This technology represents a significant step towards achieving a more sustainable future, where synthetic materials can be replaced with natural alternatives.

The exploration of mycelial fibers as a sustainable alternative to synthetic materials marks a significant advancement in the field of materials science. The simple yet effective method developed by researchers at Shinshu University opens up new possibilities for utilizing mushroom-based materials across a wide range of applications. Through their low environmental impact, biodegradability, and cost-effectiveness, mycelial fibers offer a promising solution to the global waste problem. With further research and development, these sustainable materials have the potential to transform industries, contribute to a circular economy, and promote a greener future for generations to come.

Leave a Reply