Lithium metal batteries (LMBs) have gained attention as a potential candidate for energy storage due to their higher energy density compared to other materials. However, the use of a lithium metal anode presents challenges stemming from the interface between the electrode and electrolyte. The formation of a solid-electrolyte interphase (SEI) on the lithium metal anode leads to poor lifespan and performance. To address these issues, researchers have investigated the potential of artificial solid electrolyte interphase (ASEI) as a substitute for the natural SEI. The development of ASEI has the potential to enhance the safety, reliability, and power capability of lithium metal batteries, making them a more viable option for electric vehicles and other applications.

The reactivity of lithium metal with the electrolyte leads to the formation of a passivation layer, known as the solid-electrolyte interphase (SEI), during battery operation. Unfortunately, the natural SEI is brittle and fragile, resulting in poor performance and limited lifespan. Furthermore, the growth of dendrites on the lithium metal anode during battery charging poses safety hazards and reduces the practicality of LMBs.

Strategies for Improving Lithium Metal Anode

Researchers have identified several strategies to overcome the limitations of the lithium metal anode and enhance its performance. One approach is to homogenize the distribution of lithium ions within the battery, which can reduce deposits on negatively charged areas and subsequently reduce dendrite formation. This can help prevent premature decay and short-circuiting, improving the overall functionality of the battery.

Additionally, facilitating the diffusion of lithium ions while ensuring electrical insulation between layers is essential for maintaining the structural and chemical integrity of the battery during cycling. By reducing the strain between the electrode and electrolyte interface, proper connectivity can be achieved, which is crucial for the efficient operation of the battery.

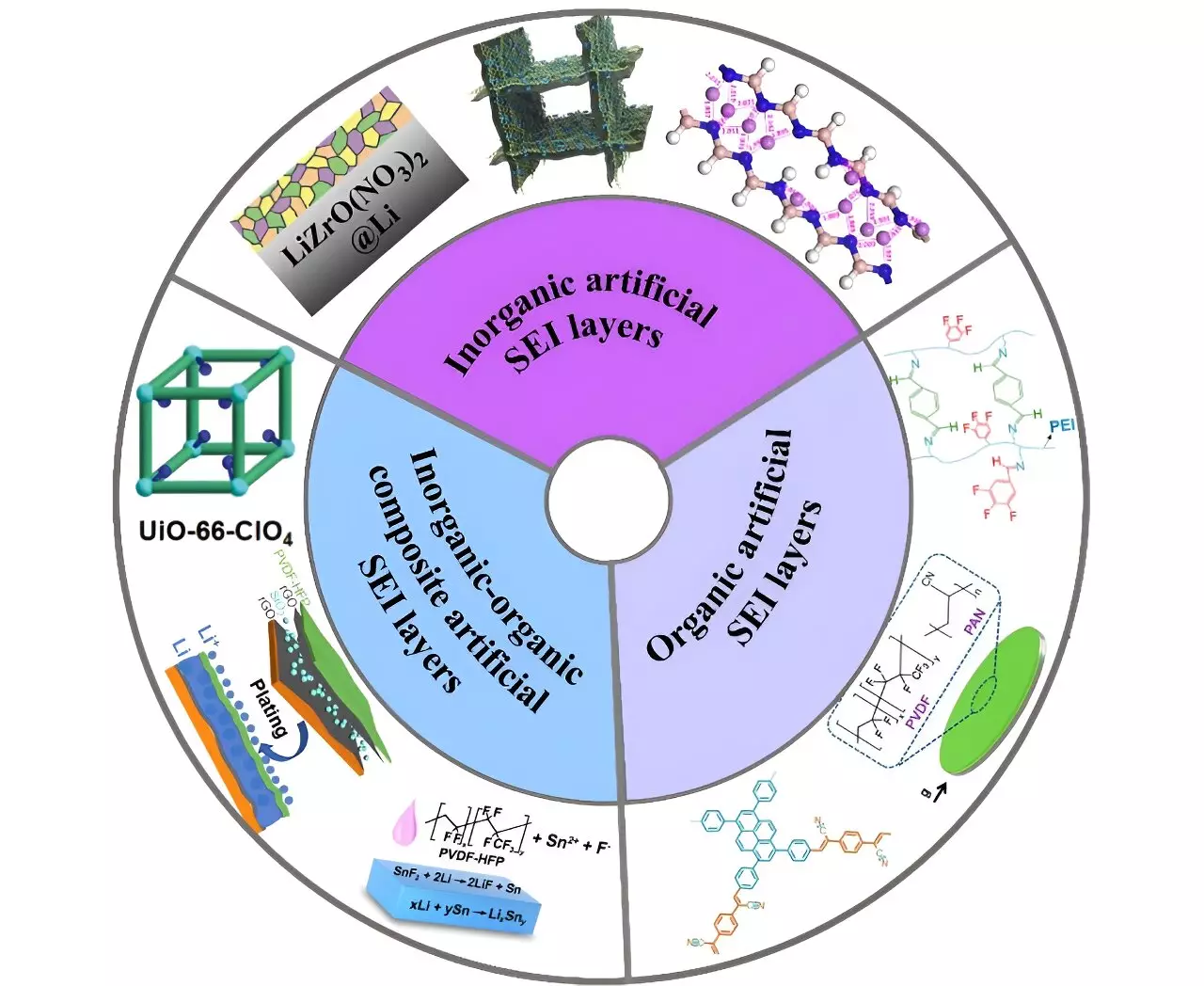

Among the strategies explored, polymeric ASEI layers and inorganic-organic hybrid ASEI layers show the most potential. Polymeric layers offer adjustability in design, allowing for easy customization of strength and elasticity. They also have functional groups similar to electrolytes, resulting in compatibility that other components lack.

On the other hand, inorganic-organic hybrid layers offer advantages such as reduced layer thickness and improved distribution of components within the layers. These improvements contribute to enhanced overall battery performance.

While the promise of ASEI layers is evident, further improvements are necessary to fully harness their potential. One area of focus is improving the adhesion of ASEI layers to the metal surface, as it directly affects the function and longevity of the battery. Additionally, stability in the structure and chemistry of the layers needs to be addressed to ensure long-term performance and reliability. Minimizing the thickness of the layers is also crucial to improve the energy density of the metal electrodes.

Once these challenges are overcome, the future looks promising for lithium metal batteries with ASEI layers. The development of these enhanced batteries will pave the way for a carbon-free economy and provide better performance compared to current lithium-ion batteries.

The use of lithium metal anodes in batteries offers higher energy density, making them an attractive option for various applications. However, the limitations associated with the electrode-electrolyte interface must be addressed for the widespread use of lithium metal batteries. Artificial solid electrolyte interphase (ASEI) layers have emerged as a potential solution to enhance the safety, reliability, and power capability of these batteries. Strategies such as homogenizing lithium ion distribution, facilitating ion diffusion, and reducing strain at the interface show promise. Polymeric ASEI layers and inorganic-organic hybrid ASEI layers offer substantial advantages in terms of adjustability, compatibility, and overall performance improvement. However, challenges remain in areas such as adhesion, stability, and layer thickness. Despite these challenges, the future of lithium metal batteries with ASEI layers appears bright. With continued research and development, these batteries may revolutionize the energy storage industry and contribute to a carbon-free economy.

Leave a Reply