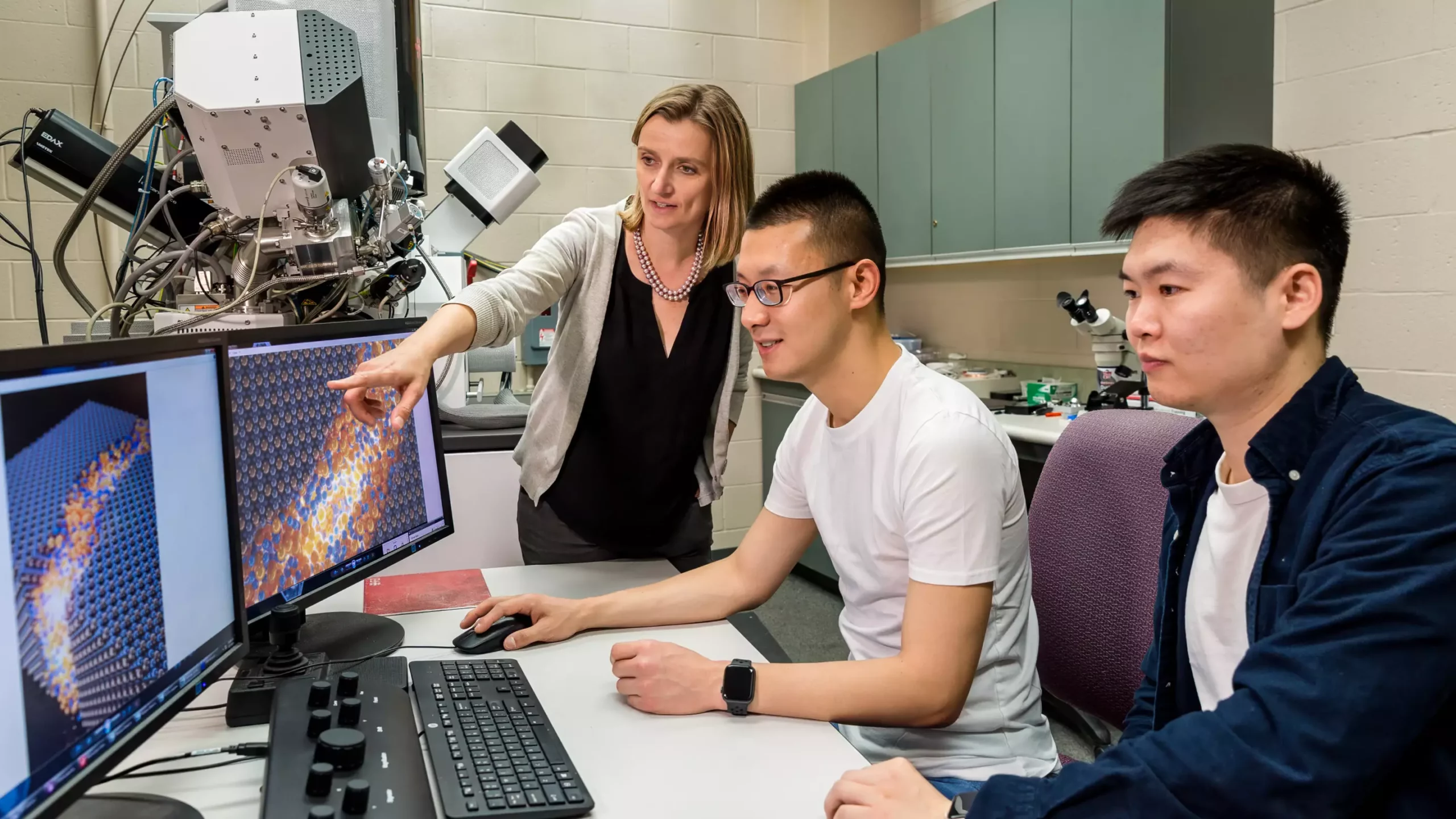

In a breakthrough study, researchers at the University of Wisconsin–Madison have shattered conventional wisdom in the field of materials science and engineering. Contrary to popular belief, shear bands, normally associated with material failure, can actually enhance the ductility of certain materials under specific conditions. Led by Izabela Szlufarska, a distinguished professor in the field, the team’s findings were published in the prestigious journal Nature Materials. With a combination of experimental characterization and simulations, they have uncovered potential strategies to harness the power of shear bands, presenting new possibilities for improving material toughness.

Seeking a better understanding of the conditions under which shear bands form and their effects, Szlufarska and her team delved deeper into this intriguing subject. Their previous study showcased the beneficial effects of shear bands in a material called samarium cobalt. This prompted them to investigate further, determining when to encourage their formation and when to avoid them.

Materials such as metals and ceramics possess structural irregularities, known as dislocations, which allow them to bend without breaking their rigid structure. However, if these dislocations become locked in place, the material becomes more brittle. Surprisingly, the research team discovered that in samarium cobalt, an intermetallic material used in the production of powerful magnets, amorphous shear bands increased the material’s plasticity rather than signaling failure. These shear bands acted as a lubricant, enabling atomic planes to smoothly slide without causing fractures.

Expanding the Horizons

Building upon this observation, the team proposed that beneficial shear bands could form in materials capable of transitioning between crystalline and amorphous phases. To test this hypothesis, they examined aluminum samarium, a glassy material extensively studied by Szlufarska and her colleagues. Utilizing advanced atomic-level simulations, they predicted that shear bands would also form in the crystalline form of aluminum samarium under stress. The team successfully confirmed this prediction in the lab and further manipulated the atomic composition of the material, leading to shear bands resulting in either fracture or plasticity.

With a deeper understanding of shear bands, the researchers have developed screening criteria for identifying potential materials that may exhibit similar properties and determining when shear bands can be advantageous. They envision utilizing these parameters to search databases for materials that could benefit from doping or engineering to promote shear band formation. By increasing the toughness of materials, they aim to enhance their ability to withstand higher levels of stress or energy before breaking.

Szlufarska expresses her enthusiasm, stating, “Doubling, tripling, or even quadrupling a material’s toughness could have a profound impact. In our study, we expanded our findings to a new class of materials, but this is just the beginning.” The team plans to investigate traditional structural materials such as oxides, carbides, and borides to uncover ways to optimize their properties.

“We now possess a much deeper understanding of this phenomenon and the factors involved,” Szlufarska adds. “I firmly believe we have unlocked the key to designing such materials, and our next step is to explore other material classes.” With their groundbreaking research, the team is poised to revolutionize the field of materials science and engineering, paving the way for the development of stronger and more durable materials in the future.

The discovery of the surprising benefits of shear bands marks a turning point in materials science. It challenges our long-held assumptions about the role of shear bands in material failure and opens up new avenues for enhancing material toughness. By harnessing the power of shear bands, scientists can potentially create materials that can endure higher stress levels and energy without breaking.

This breakthrough study conducted by the researchers at the University of Wisconsin–Madison provides a solid foundation for future investigations into the optimization of material properties. The potential to double, triple, or even quadruple a material’s toughness could have far-reaching implications across numerous industries, including manufacturing, aerospace, and construction. The ability to design and engineer stronger and more durable materials will undoubtedly shape the future of our technology and infrastructure.

As we embark on this new era of materials science, the possibilities are endless. With their groundbreaking research, Izabela Szlufarska and her team have laid the groundwork for a revolution in the field, propelling us towards a future where our materials are stronger, more resilient, and capable of withstanding harsh conditions. By continuously pushing the boundaries of knowledge, we are poised to unlock the true potential of materials and transform the world as we know it.

Leave a Reply