A remarkable innovation in the realm of plastic waste management has emerged from Tokyo Metropolitan University, spearheaded by Professor Kotohiro Nomura and his research team. Their pioneering work focuses on the depolymerization of PET (polyethylene terephthalate), a widely used plastic found in various consumer products, including beverage bottles and textiles. Through the utilization of alcohols and a cost-effective iron trichloride catalyst, this method promises a fresh approach to tackling the dual environmental crises of plastic pollution and waste accumulation.

Plastic waste remains an escalating global concern, with millions of tons ending up in landfills and oceans annually. Traditional recycling methods struggle to keep pace and often result in the degradation of materials, limiting their reuse potential. Only a small fraction of plastics is effectively recycled back into raw materials, with a significant gap in the efficiency of chemical recycling processes. Innovations in this field are vital, as the need for sustainable waste management has never been more pressing.

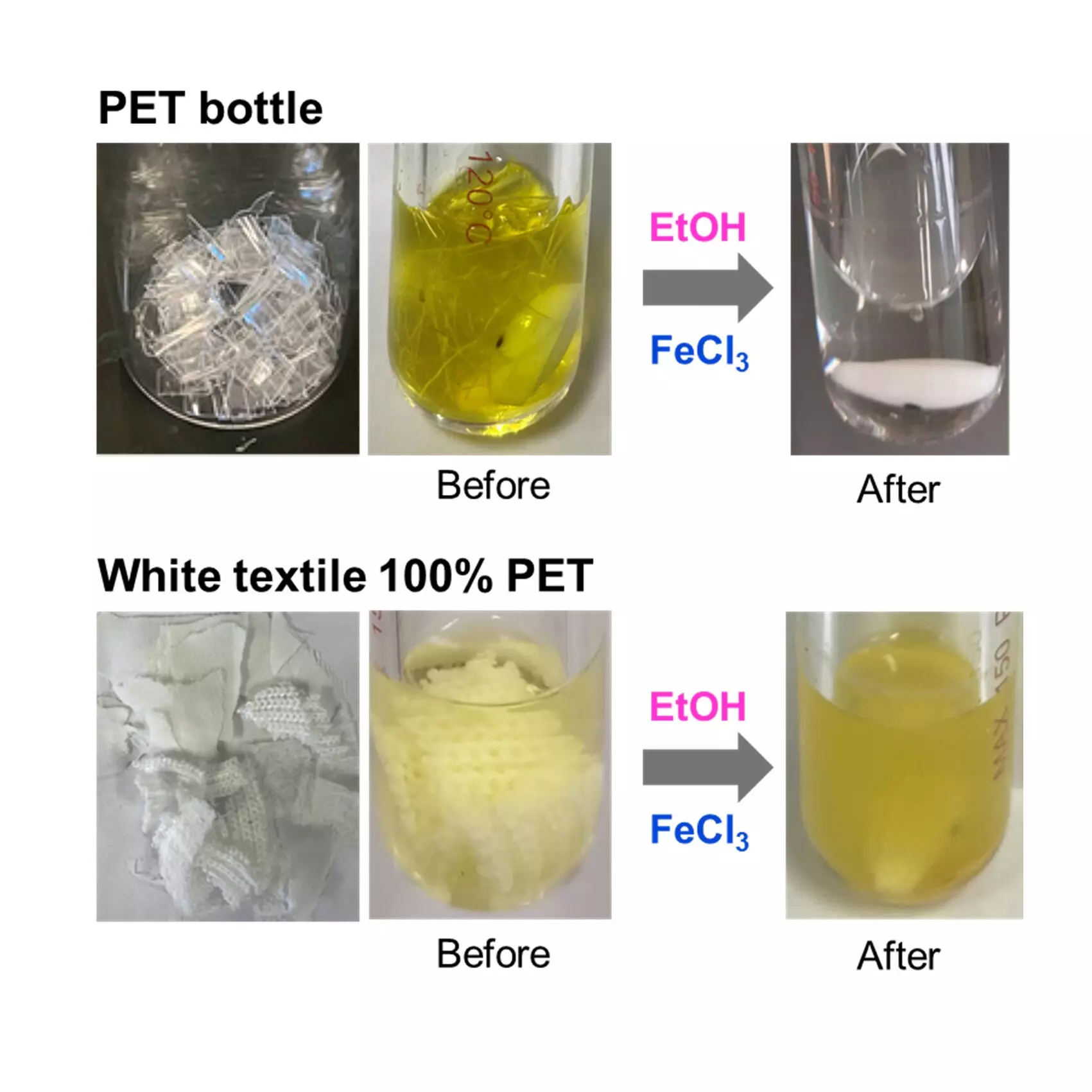

Polyesters, the chemical compounds characterized by repeating ester bonds formed through the reaction of carboxylic acids and alcohols, are abundant in many everyday materials. The ability to deconstruct these polymers back to their original monomers is essential for effective recycling. While previous methods required high temperatures and large quantities of corrosive substances, the new technique proposed by Nomura’s team is both simpler and environmentally friendly. This approach hinges on breaking down the ester bonds using ethanol and an iron chloride (FeCl3) catalyst, operable at moderate temperatures between 160°C and 180°C.

One of this method’s standout achievements is its ability to selectively recycle PET from complex mixtures. Notably, it can effectively separate and depolymerize PET found in textile waste, such as polyester-cotton blends, while recovering cellulose content entirely. This dual capacity offers a much-needed resource extraction method from mixed waste types, promoting the efficient use of materials that would typically be discarded.

The implications of this research extend well beyond academic publication. The development of a reliable and cost-effective method for the chemical recycling of PET signals a significant step towards achieving a circular economy, where materials are continuously repurposed and reused. By providing industries with a feasible pathway to convert plastic waste back into valuable raw materials, this methodology can help mitigate the environmental impacts of plastic production and consumption.

The innovative method developed by Professor Nomura and his team presents a breakthrough in the selective depolymerization of PET waste. With the integration of readily available catalysts and efficient chemical processes, this research not only addresses the pressing environmental challenge of plastic waste but also lays the groundwork for a sustainable future in material recycling. As the world confronts increasing plastic pollution, advancements like these are crucial for fostering a healthier planet.

Leave a Reply