The construction of arched stone windows, a centuries-old technique, has sparked a new method for creating tailor-made nanoscale windows in porous functional materials known as metal-organic frameworks (MOFs). By utilizing a molecular version of an architectural arch-forming “centering formwork” template, researchers have discovered a way to direct the formation of MOFs with predetermined shapes and sizes of pore windows. This groundbreaking technique has given rise to a range of new MOFs, from those with narrow gas separation potential to structures with potential medical applications due to their exceptional oxygen-adsorption capacity.

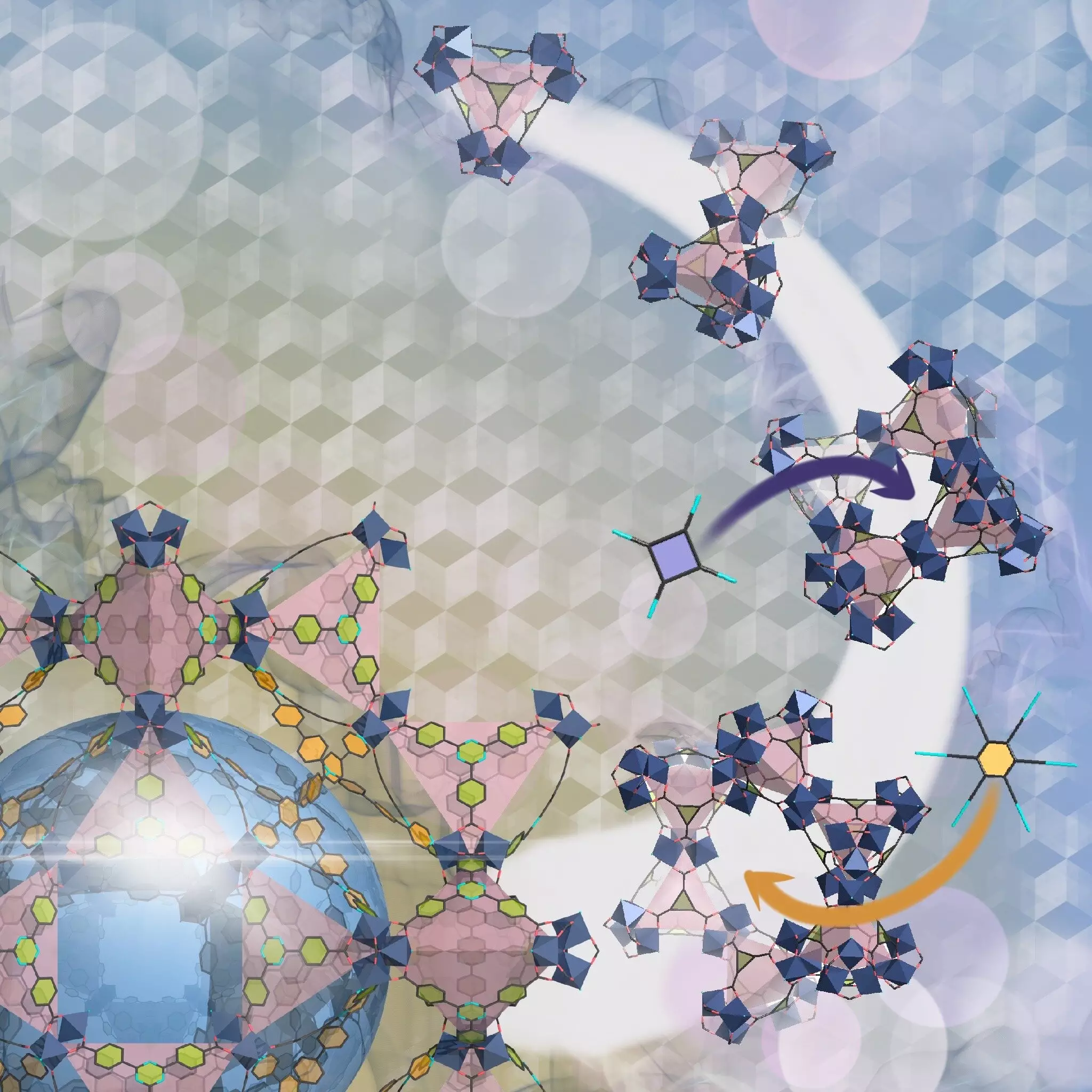

The challenge of precise control in structure formation has always been a significant goal in new structure design. It is especially crucial for reticular chemistry, which involves assembling molecular building blocks into porous crystalline materials like MOFs. The team led by Mohamed Eddaoudi recognized that the centering formwork concept might offer the much-needed precise control in reticular chemistry. Their research began with a zeolite-like MOF (ZMOF) that typically features pentagonal windows framed by supertetrahedra (ST) building blocks. However, the team aimed to transform the ST arrangement and create new shapes and sizes of ZMOF windows using centering structure-directing agents (cSDAs) to control the ST alignment.

The size and volume of MOF pores are critical parameters that directly impact their applications. By manipulating the ST alignment through the cSDA concept, the team was able to create MOFs with both small and large windows. One of their creations, Fe-sod-ZMOF-320, exhibited the highest oxygen adsorption capacity among all known MOFs. This property is particularly valuable in industries such as medicine and aerospace, where increased oxygen storage or smaller transport cylinders are highly desirable. Additionally, the same ZMOFs demonstrated excellent performance in storing methane and hydrogen, highlighting their potential as potential fuels.

Aside from their impressive gas storage capabilities, the cSDA concept also offers other benefits that enhance MOF performance. By partitioning large windows into smaller ones, the researchers believe the cSDA concept will be useful for chemical separations. Moreover, the additional internal pore surface generated by the cSDA helps improve gas storage, while reinforcing the MOF framework enhances the material’s overall stability. Vincent Guillerm, a research scientist in Eddaoudi’s group, emphasizes the potential of the centering approach in reticular chemistry, particularly in producing made-to-order MOFs for energy security and environmental sustainability applications.

The revolutionary technique inspired by centuries-old arched stone windows has opened up a new avenue in the formation of tailor-made nanoscale windows in metal-organic frameworks. By employing a molecular version of an architectural centering formwork, researchers have achieved precise control over the formation of MOFs, resulting in structures with predetermined shapes and sizes of pore windows. These newly designed materials exhibit remarkable features, such as exceptional oxygen adsorption capacity, potential for gas separation, and improved stability. With the centering approach, which holds immense promise in reticular chemistry, the possibilities for customized MOFs for applications in energy security and environmental sustainability seem boundless.

Leave a Reply