The development of metallurgy in ancient times marked a significant leap in human civilization. The earliest blacksmiths discovered a fascinating phenomenon: by bending or hammering metals, the materials became stronger. This foundational understanding led to the practice known as work or strain hardening, a principle still integral to modern industries. From automotive fabrication to power grid infrastructure, work hardening has become a key technique employed by engineers and manufacturers to enhance the strength and durability of materials.

However, despite its importance, scientists had never succeeded in studying the minute details of this process as it occurs—until recently. A pioneering study conducted by researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) sheds new light on the mechanisms driving work hardening, presenting an unprecedented opportunity to advance material science.

The research team at the Harvard Materials Research Science and Engineering Center (MRSEC) has made notable strides in understanding the real-time dynamics of work hardening. Prior to this, scientists relied heavily on indirect methods; they could only view the atomic structure of metals through electron microscopy, limiting their insight into the processes happening during deformation. By observing the atomic structure only before and after stress was applied, a crucial aspect of material behavior remained elusive.

Frans Spaepen, a senior author of the study and Franklin Professor of Applied Physics at SEAS, emphasized the need for a more profound understanding of work hardening. Current large-scale computer models could be significantly enhanced if the underlying principles of this process were better understood. The new findings, published in the esteemed journal Nature, grant a “real-time window” into work hardening’s universal processes and how they can be modeled more effectively.

Colloidal Crystals: A New Paradigm

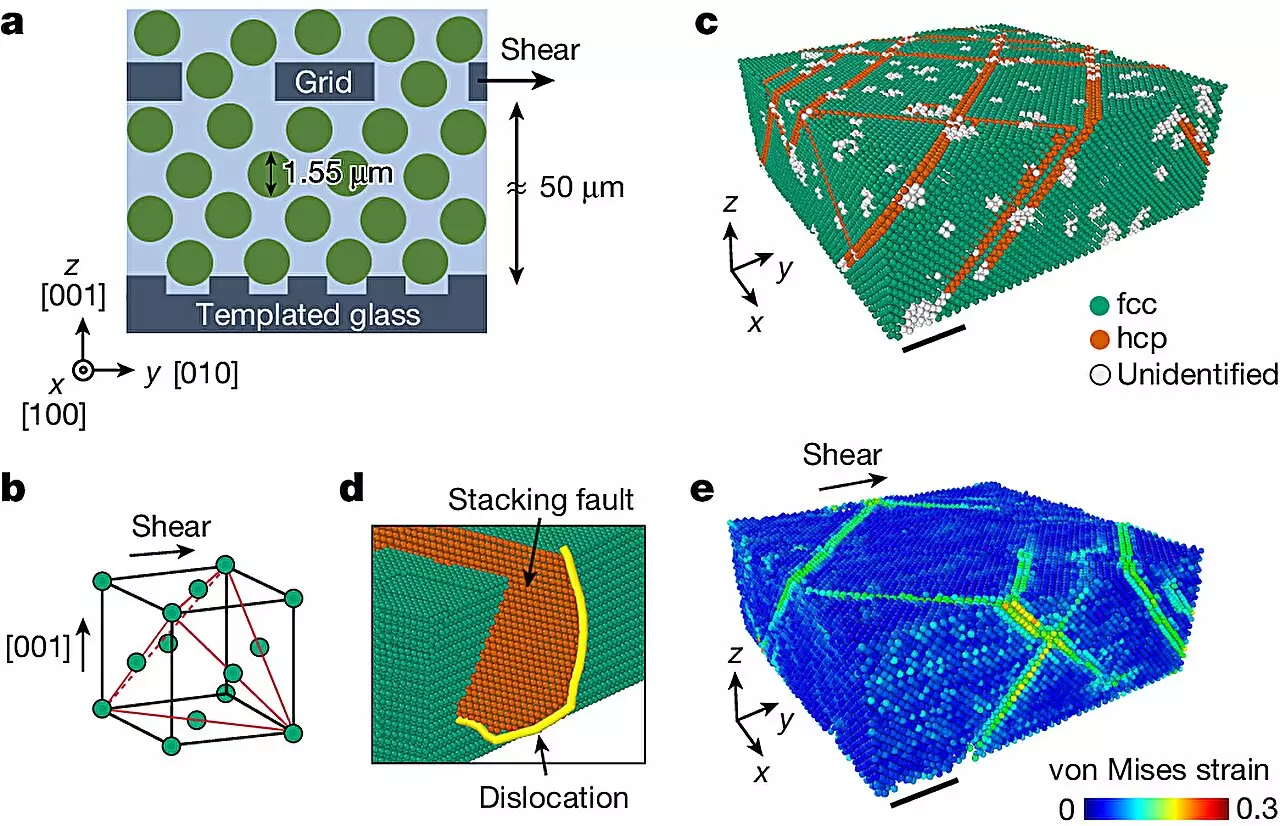

In a creative departure from conventional methods, researchers focused on colloidal crystals—particles significantly larger than atoms that can spontaneously form crystal structures under certain conditions. These crystals mimic atomic behavior yet provide a softer, more accessible system for investigation. The ingenious choice of colloidal crystals, which are about 10,000 times larger than atoms, enabled the research team to visualize the individual movements of the particles as strain was applied.

The researchers used confocal optical microscopy to observe and document the behavior of millions of particles within these soft colloidal crystals. Contrary to expectations, these low-density systems demonstrated remarkable work hardening behavior—proving even more potent than traditional metals like aluminum and copper when accounting for particle size. By viewing the mechanics of soft materials, the researchers could expand their understanding of how work hardening occurs universally across diverse material systems.

At the heart of this research lies the role of defects, specifically dislocations, which have long been known to play a pivotal role in work hardening. As the colloidal crystals were subjected to strain, the dislocation defects dynamically interacted and became entangled, altering the crystals’ overall strength. This intricate interplay among the defects resulted in a much higher density of flaws within the structure, thereby enhancing the material’s strength.

Seongsoo Kim, a graduate student involved in the research, shared the unexpected revelation that these simple interactions among particles led to robust work hardening outcomes. It was initially presumed that the simplistic nature of colloidal particles would not yield significant results in this regard. Nevertheless, the findings underscore a fascinating aspect of material science: the geometry and interactions among defects can influence the mechanical properties of materials, rendering even the softest substances surprisingly strong.

The implications of this groundbreaking research are profound, suggesting that principles observed in colloidal systems may be inherent in all materials, regardless of their structural characteristics. This understanding provides insights that can catalyze advancements in material design and engineering, opening avenues for creating stronger, more efficient materials tailored to specific applications.

As the research highlights the universal mechanisms of work hardening, the potential applications could span various industries—from aerospace to construction—revolutionizing how we approach materials engineering. By recognizing the distinct properties of both hard and soft materials, scientists can innovate, creating next-generation composites that blend strength with versatility.

The exploration of work hardening through colloidal crystals represents a significant advancement in material science. The real-time observations illuminate the critical mechanisms that govern material strength and challenge long-held assumptions. As researchers continue to unravel the intricacies of this universal phenomenon, we may be on the brink of a new era in engineering where unparalleled materials are designed to meet the demands of an ever-evolving world.

Leave a Reply